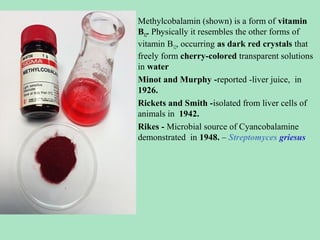

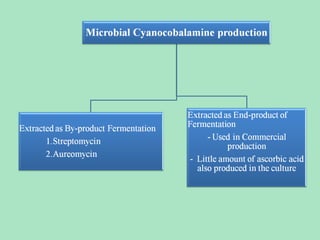

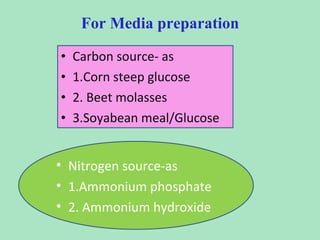

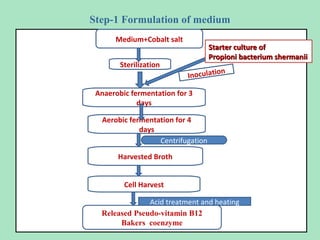

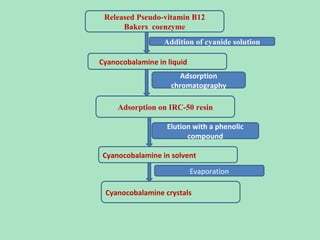

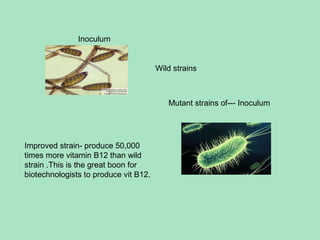

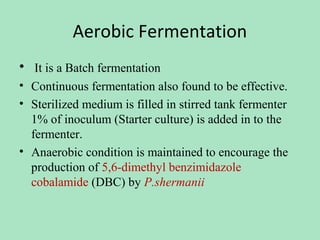

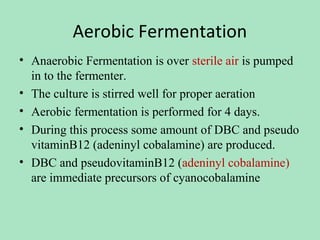

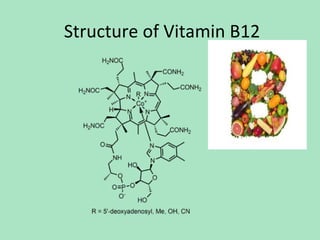

This document discusses vitamin B12, including its structure, functions, deficiency, production, and uses. It provides details on the microbial production of cyanocobalamin (vitamin B12) through fermentation using Propionibacterium shermanii. The process involves anaerobic fermentation to produce precursors, aerobic fermentation, cell harvesting, acid treatment to release precursors, addition of cyanide to produce cyanocobalamin, and downstream purification using chromatography and crystallization. Vitamin B12 is important for normal functioning of the brain/nervous system, blood formation, and cellular metabolism. Deficiency can cause anemia and fatigue.

![• Species from the following genera are known to synthesize

B12: Acetobacterium, Aerobacter, Agrobacterium, Alcaligenes,

Azotobacter, Bacillus, Clostridium, Corynebacterium,

Flavobacterium, Lactobacillus, Micromonospora,

Mycobacterium, Nocardia, Propionibacterium,

Protaminobacter, Proteus, Pseudomonas, Rhizobium,

Salmonella, Serratia, Streptomyces, Streptococcus and

Xanthomonas.

• Industrial production of B12 is through fermentation of

selected microorganisms. Streptomyces griseus, a bacterium

once thought to be a yeast, was the commercial source of

vitamin B12 for many years.[48][49] The species Pseudomonas

denitrificans and Propionibacterium shermanii are more

commonly used today](https://image.slidesharecdn.com/finalvitb12-131118085301-phpapp01/85/vitamin-B12-6-320.jpg)