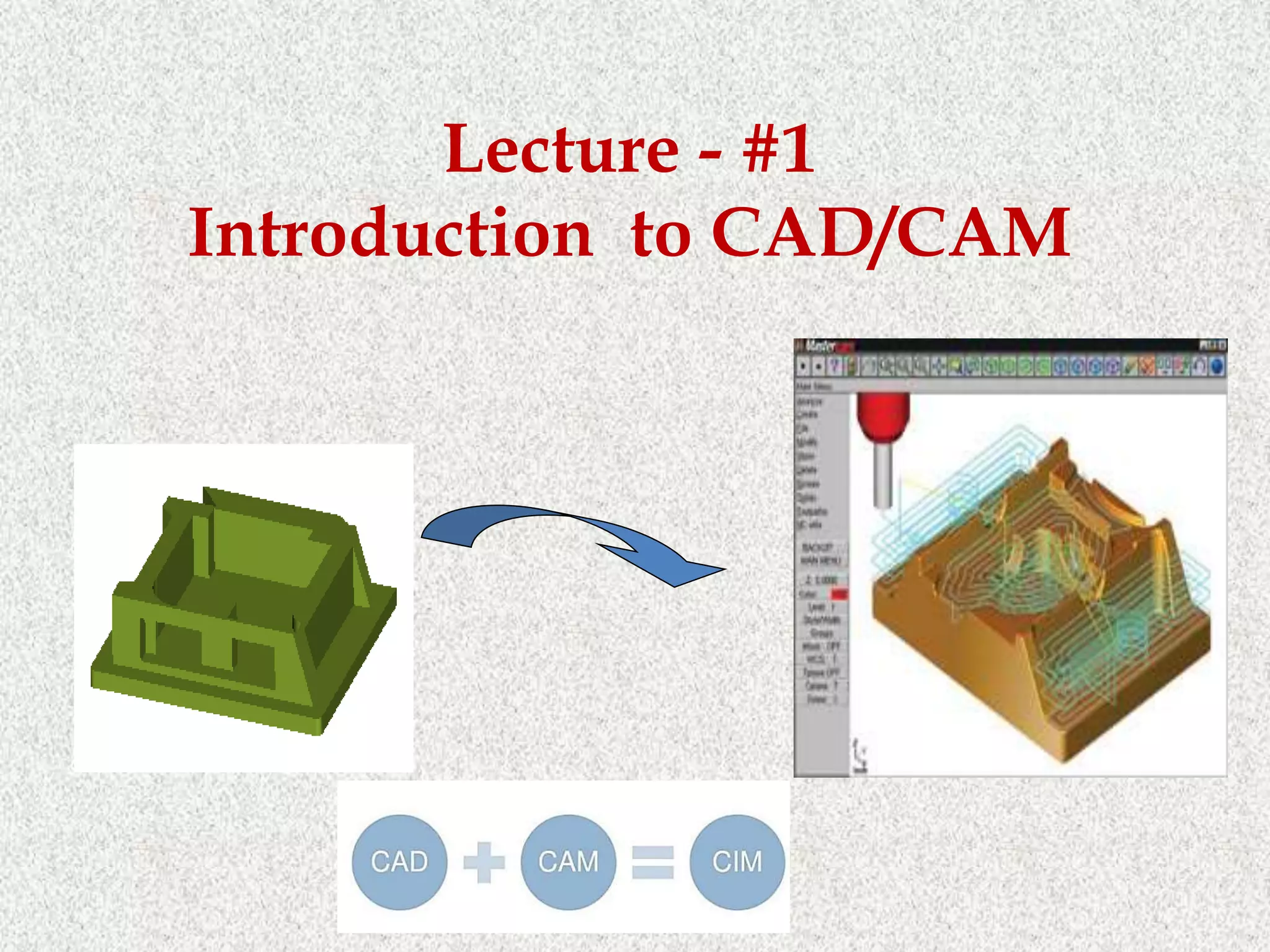

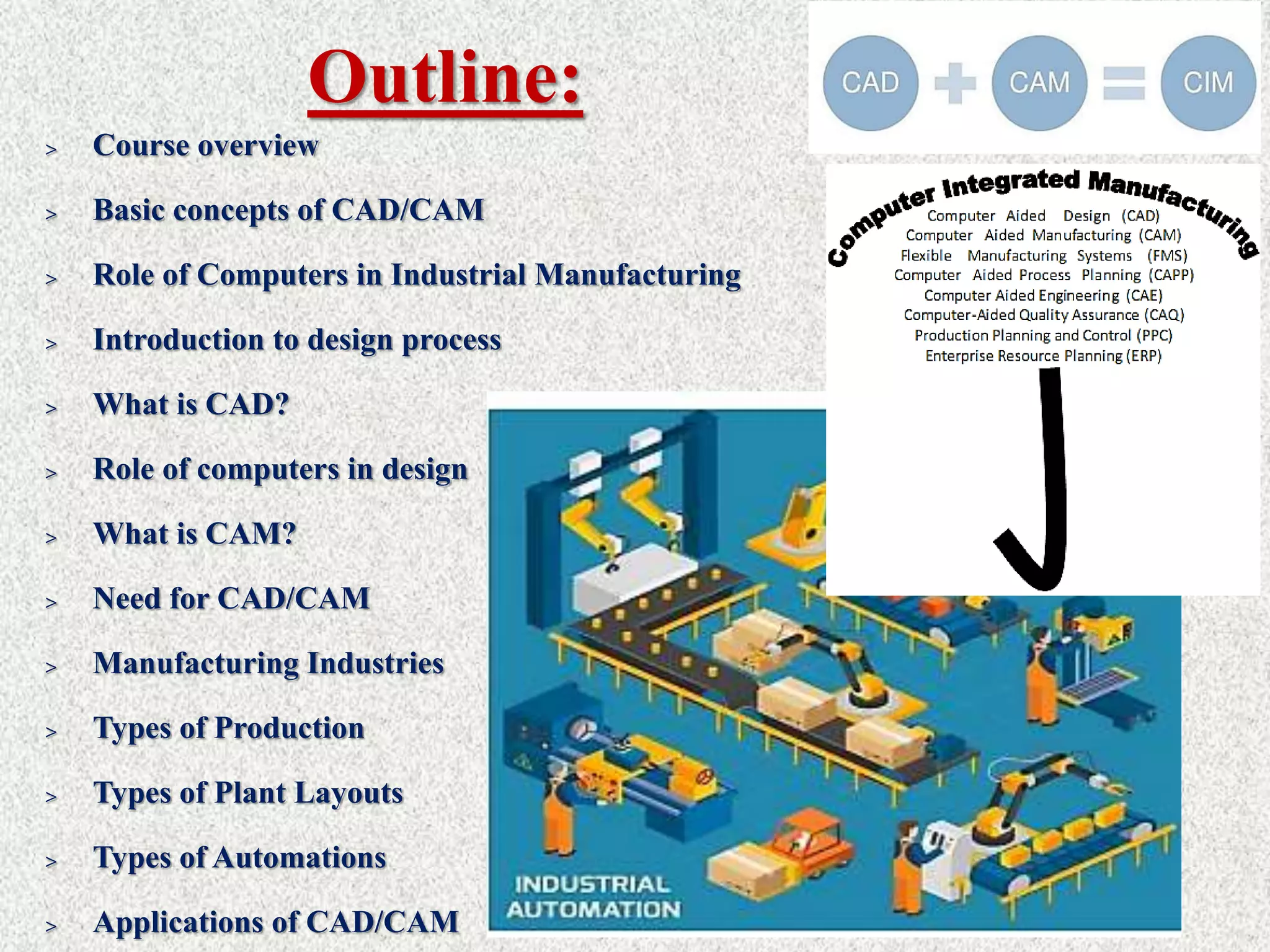

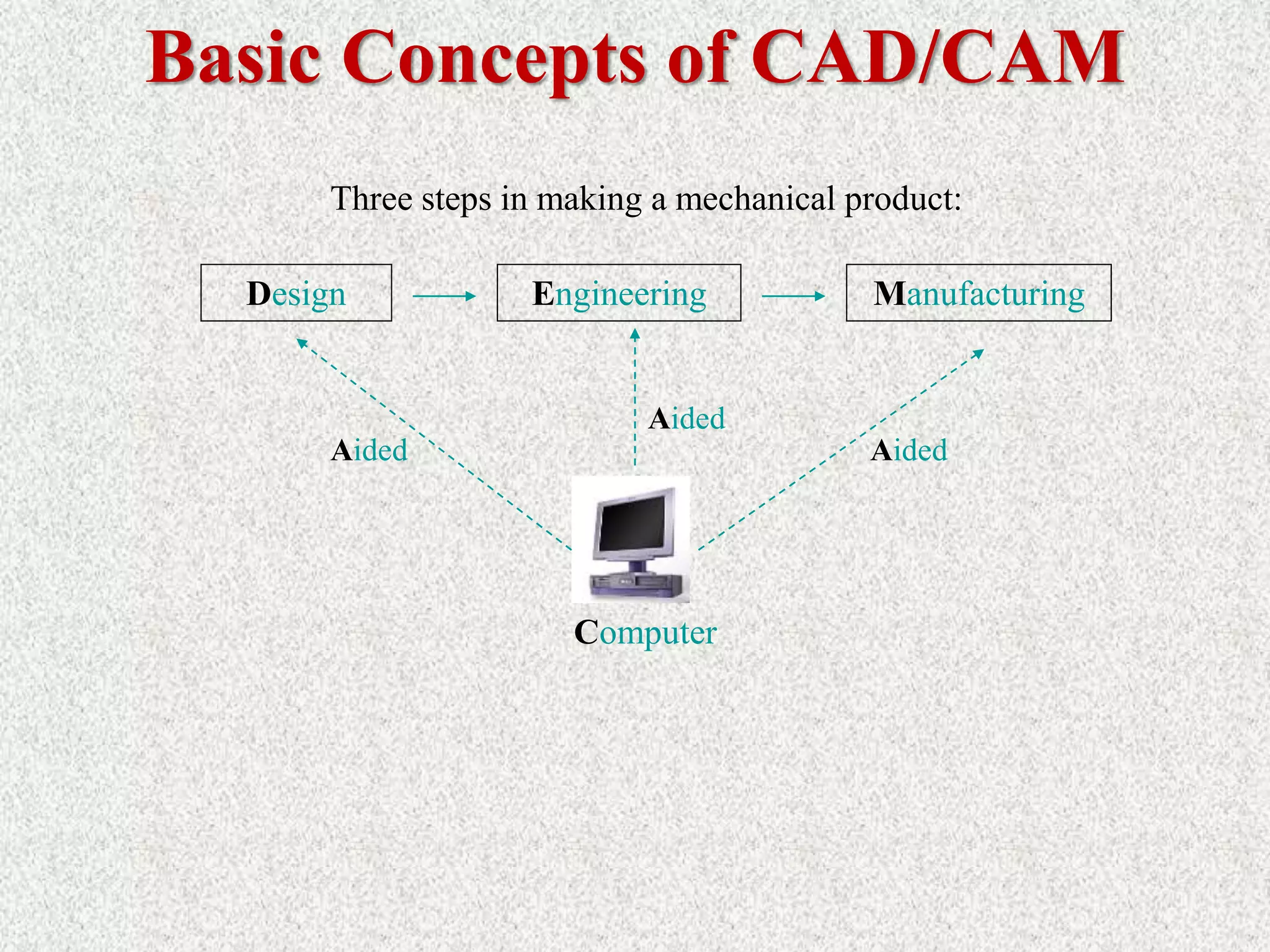

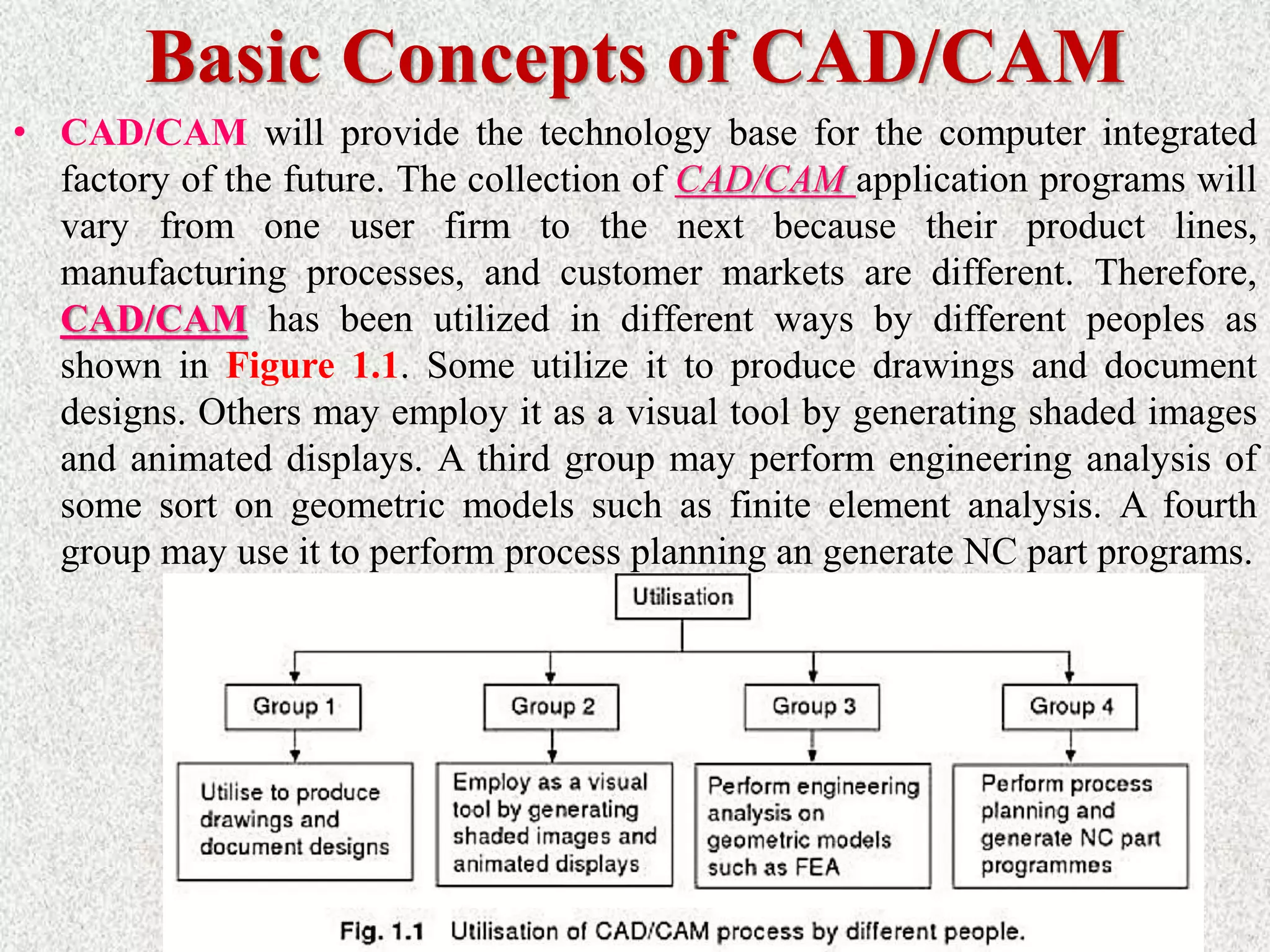

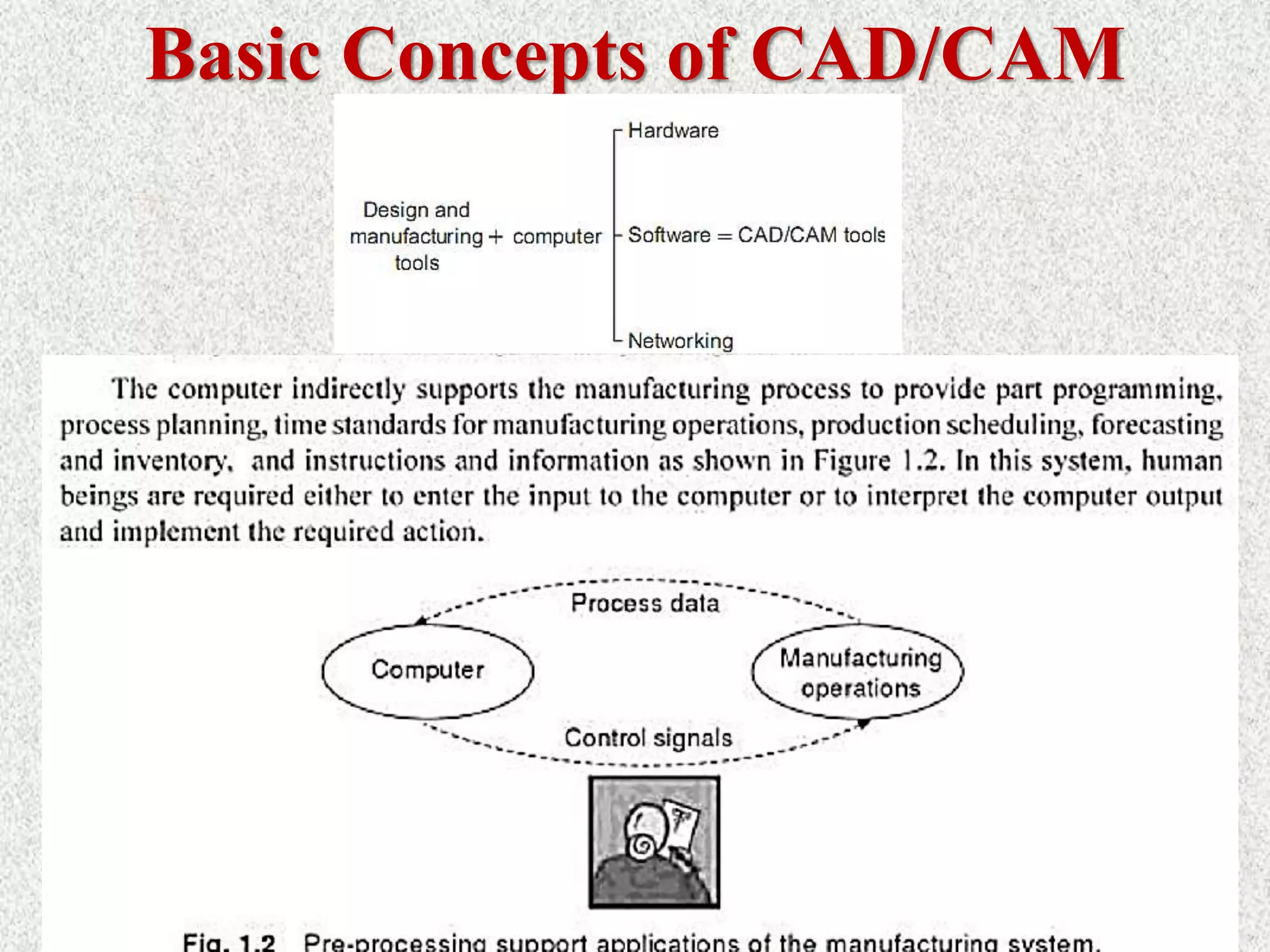

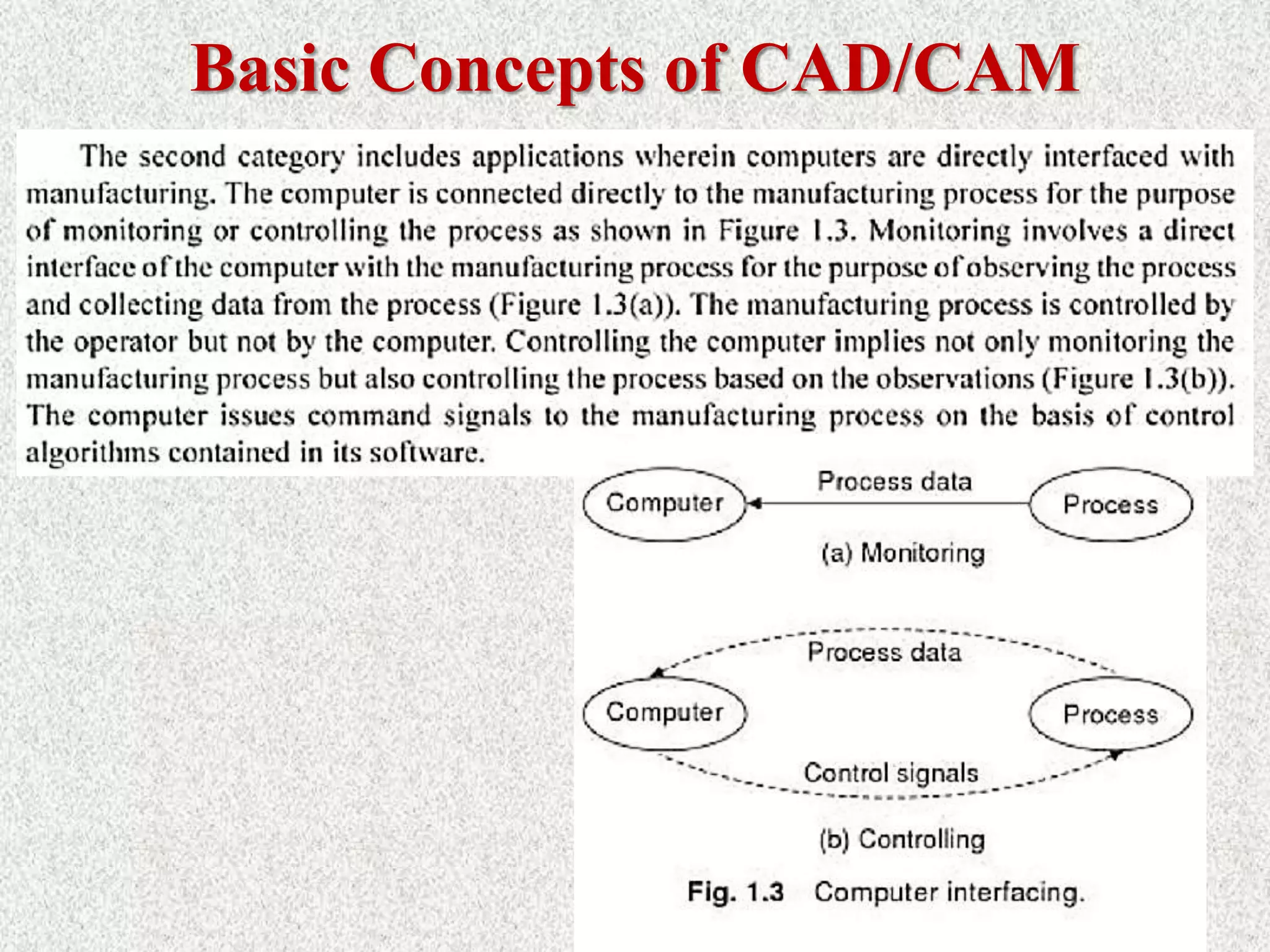

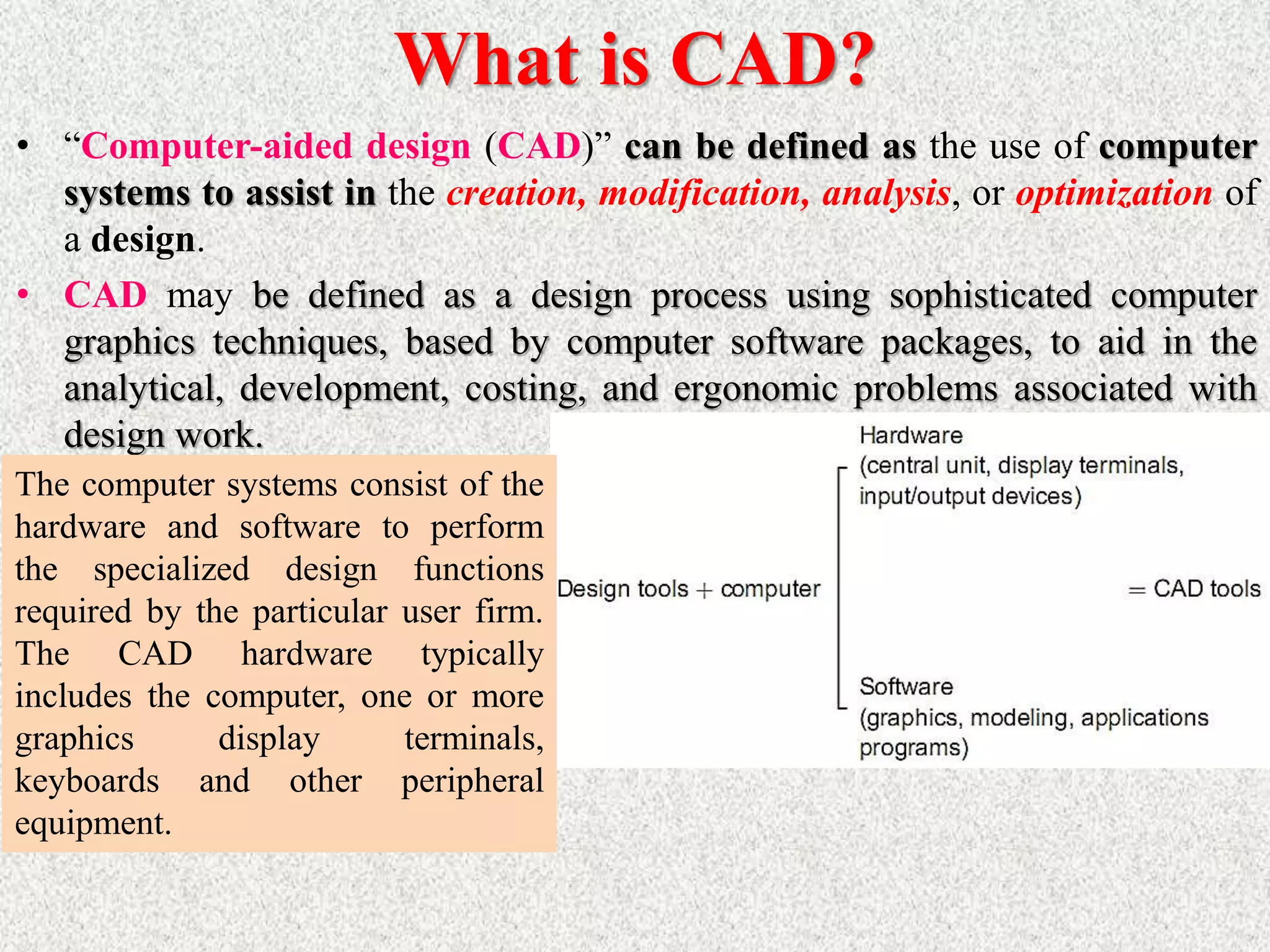

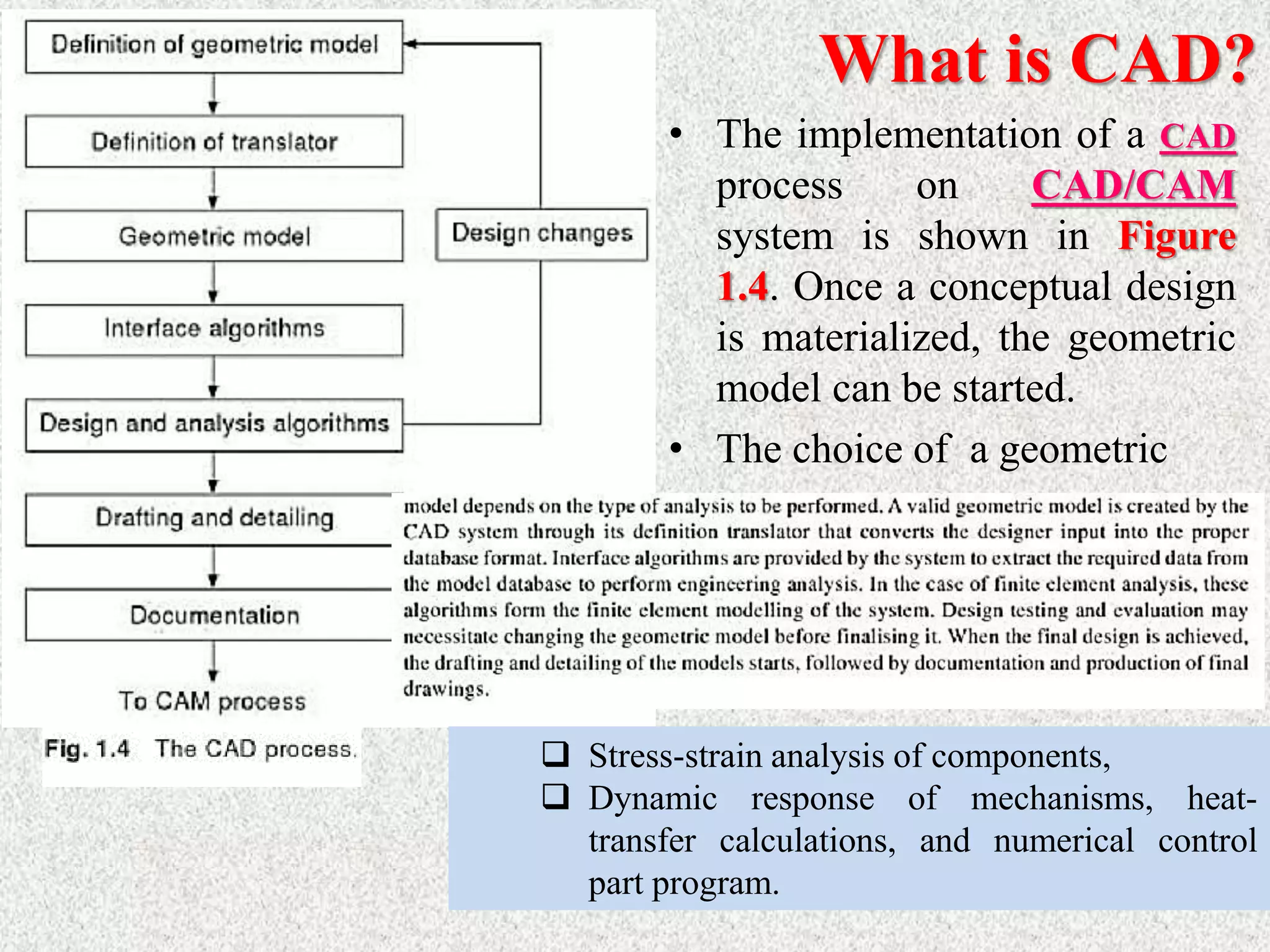

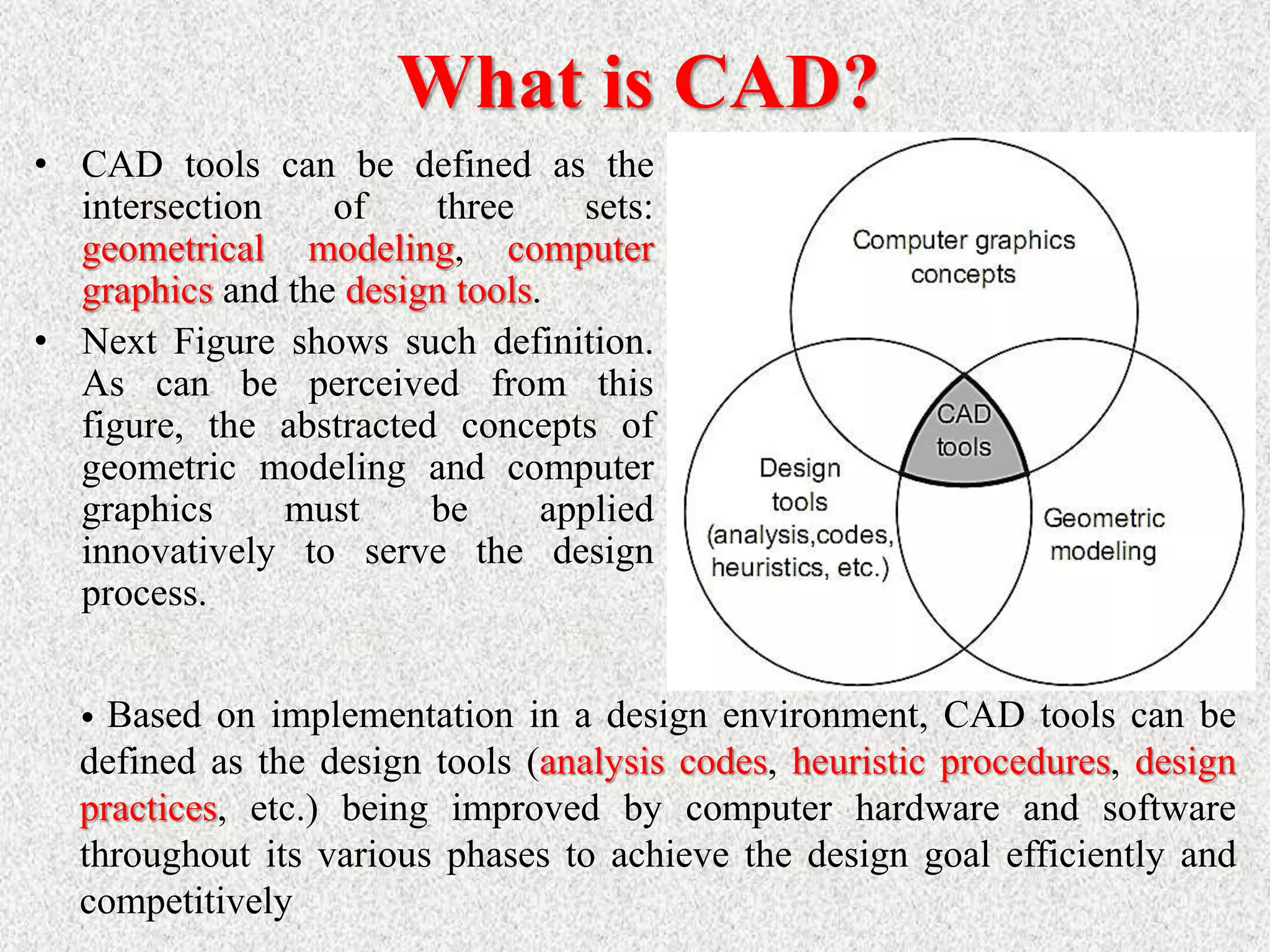

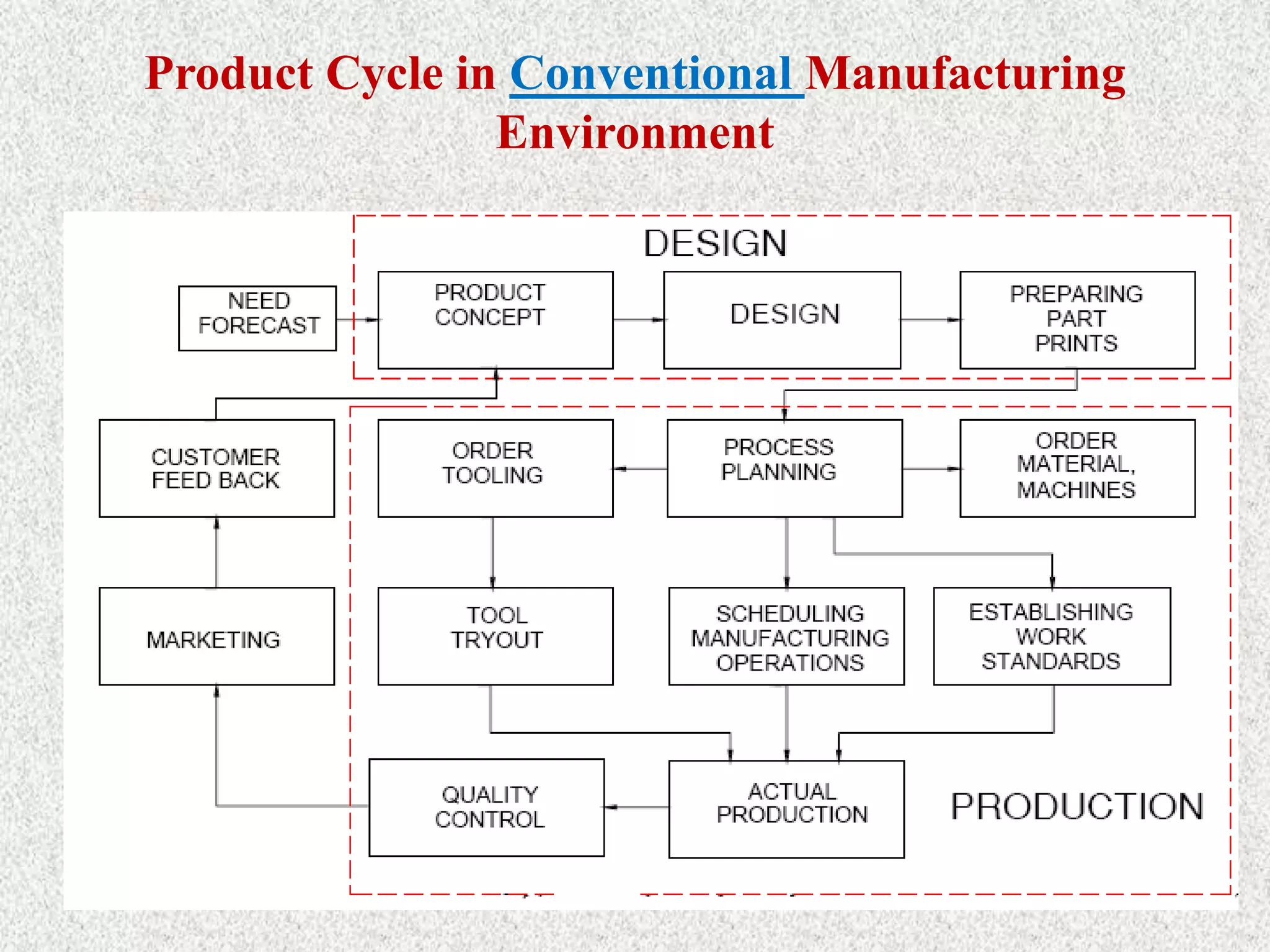

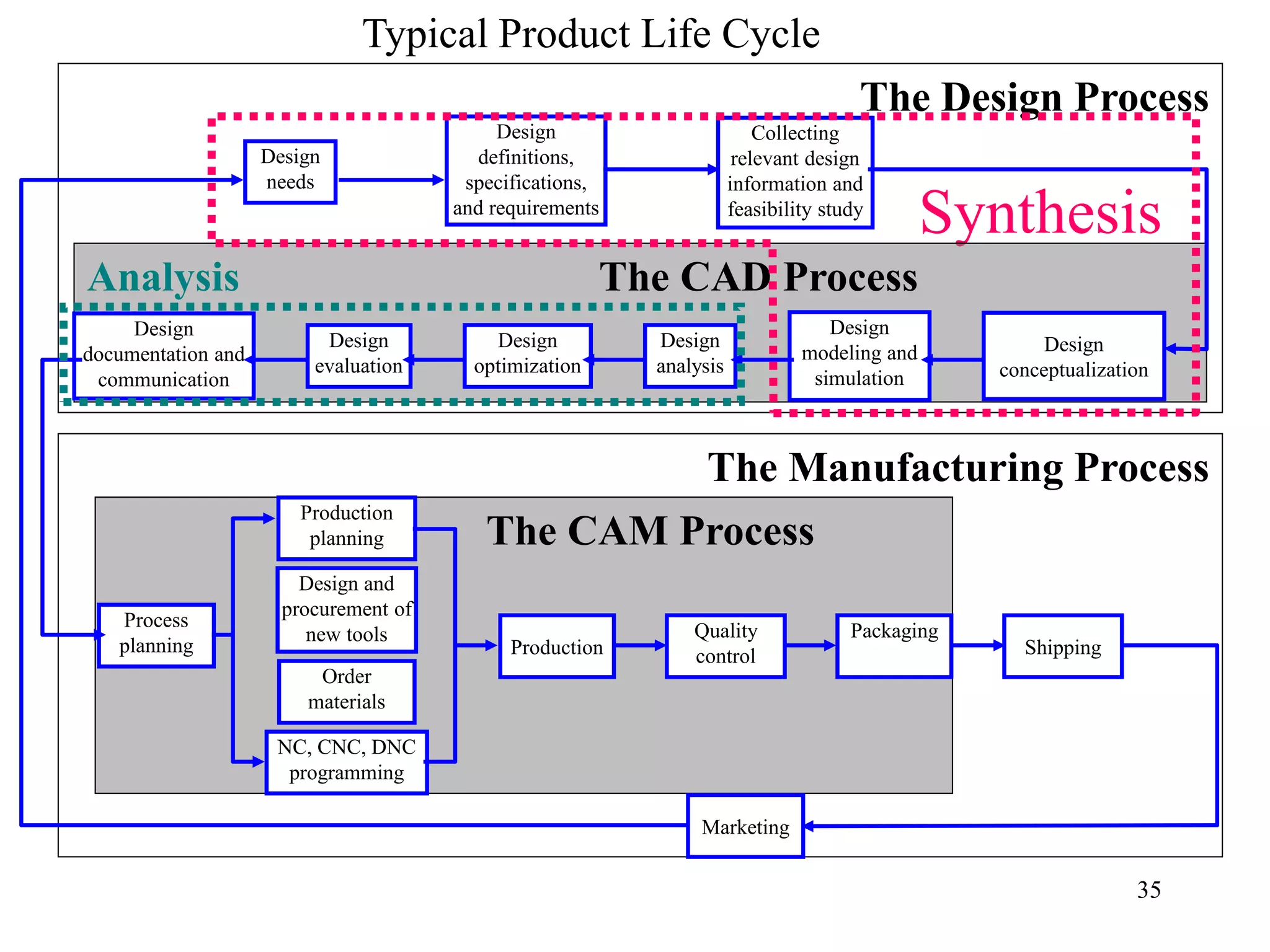

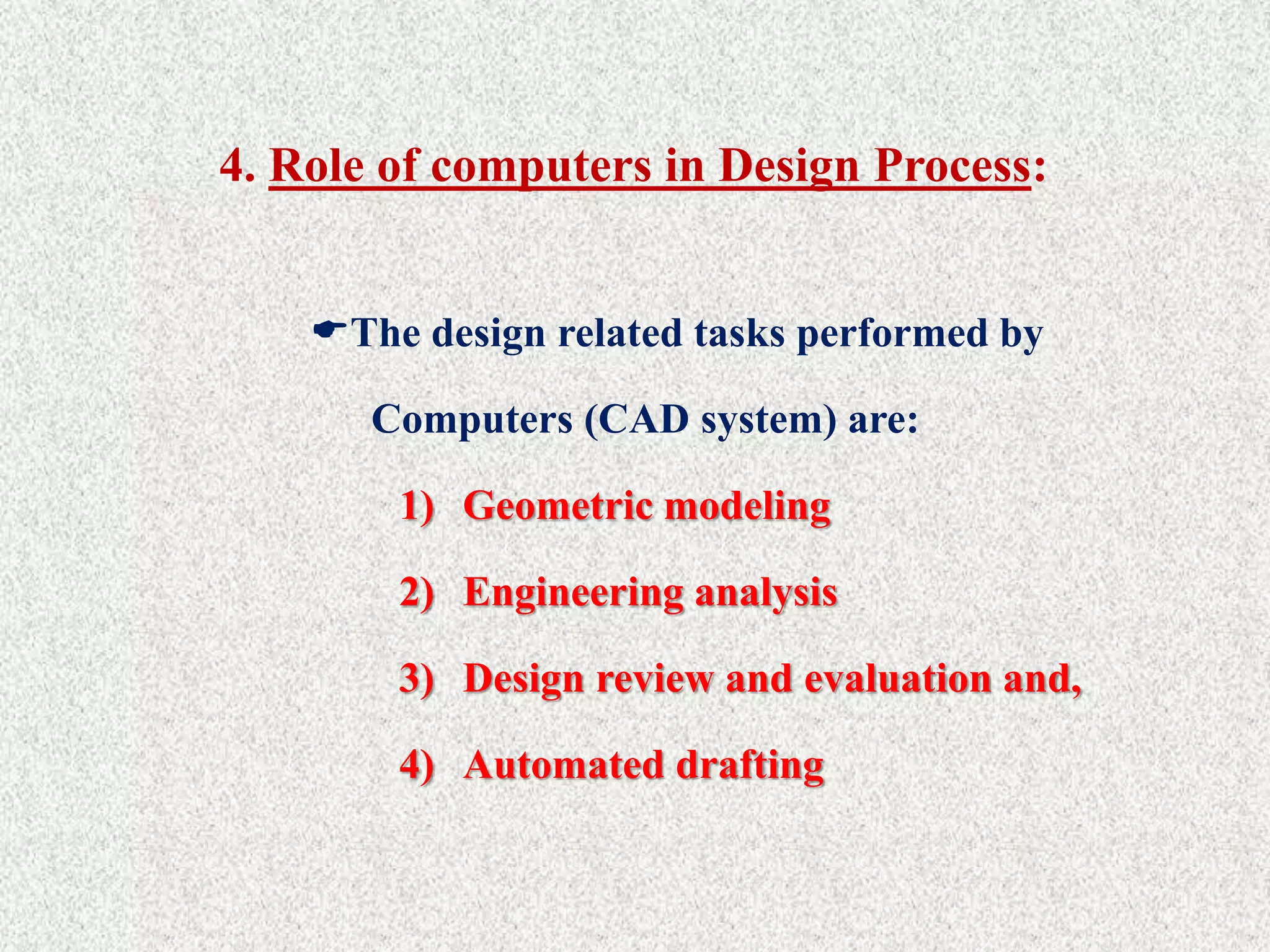

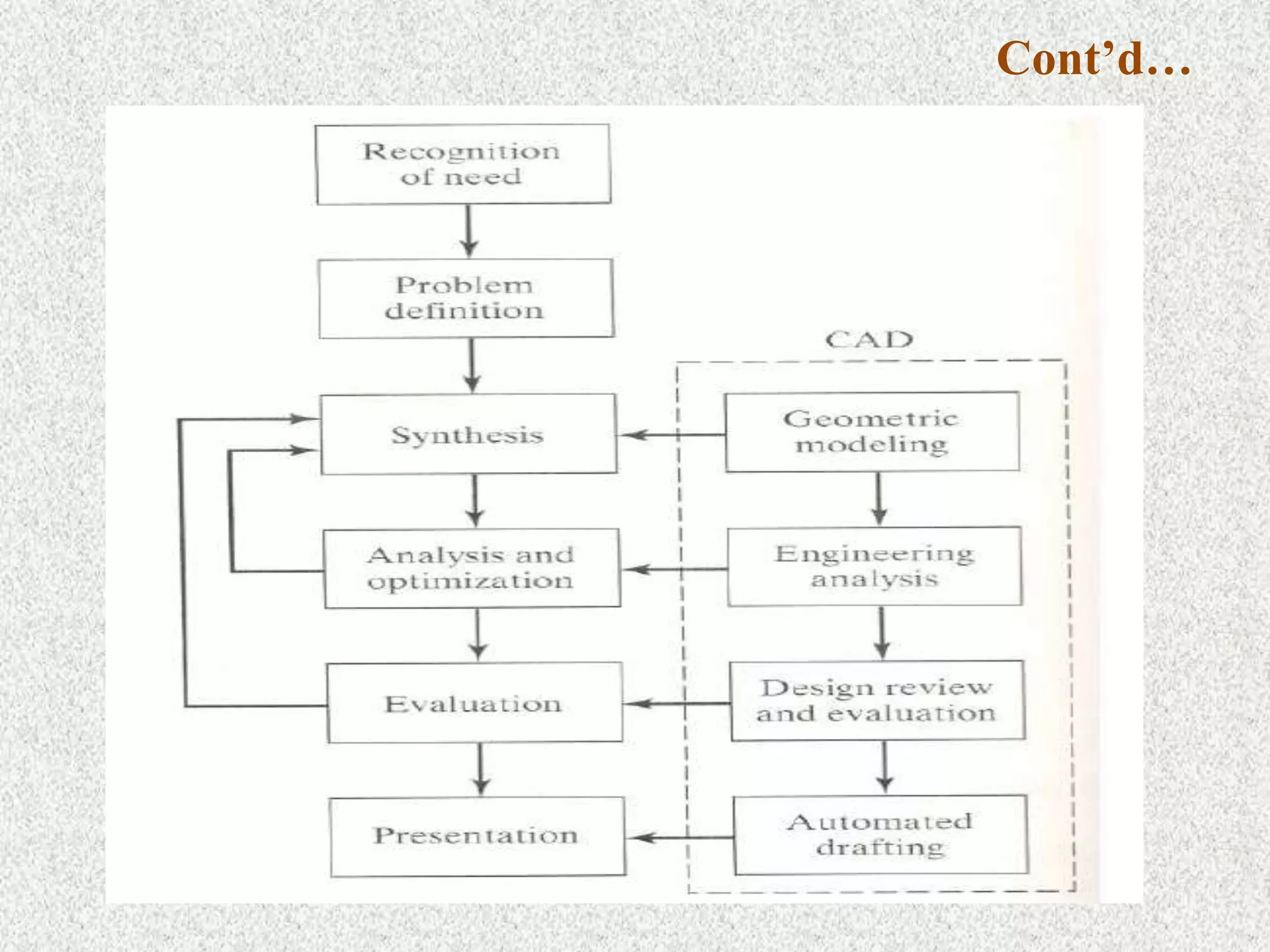

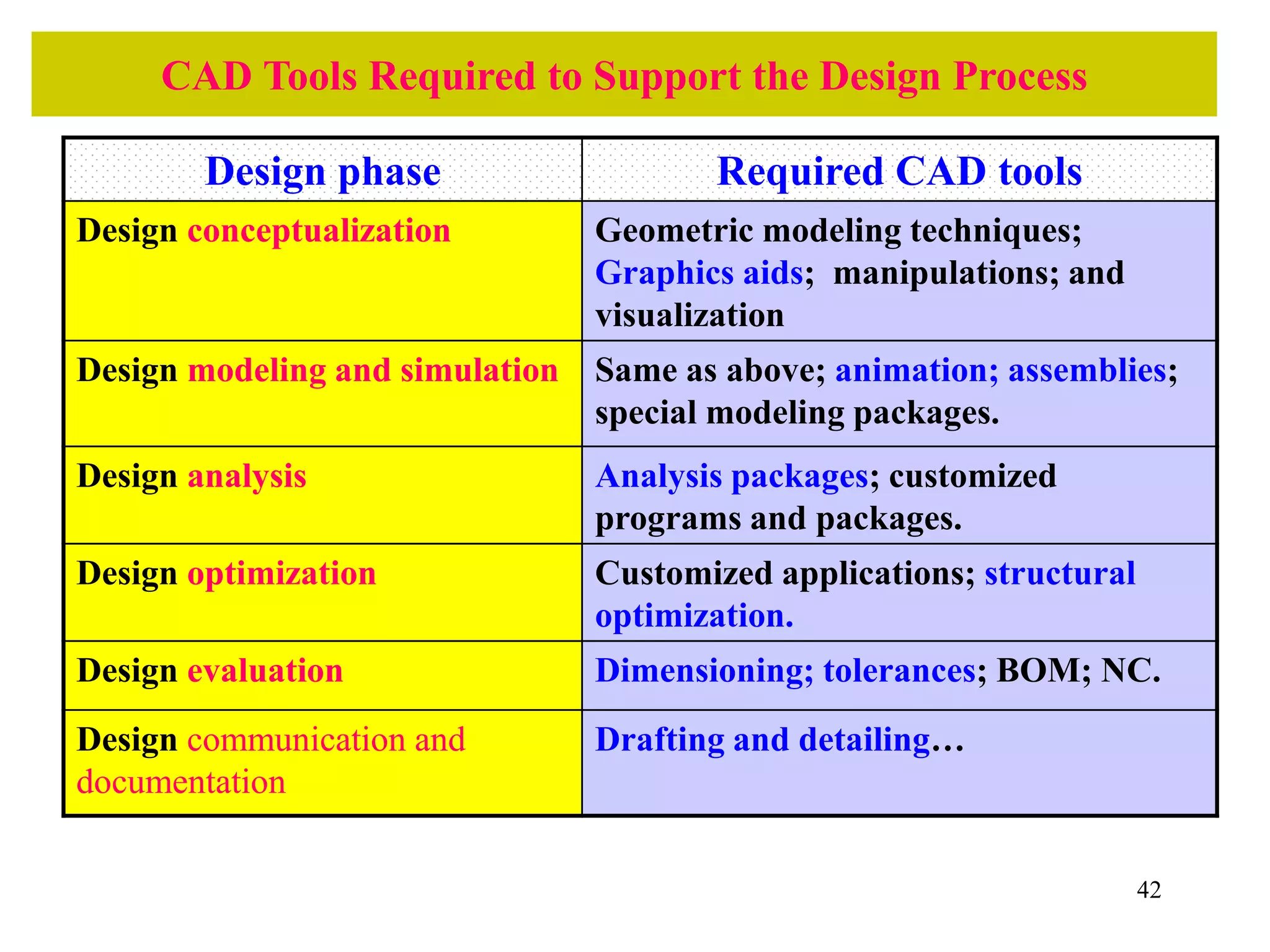

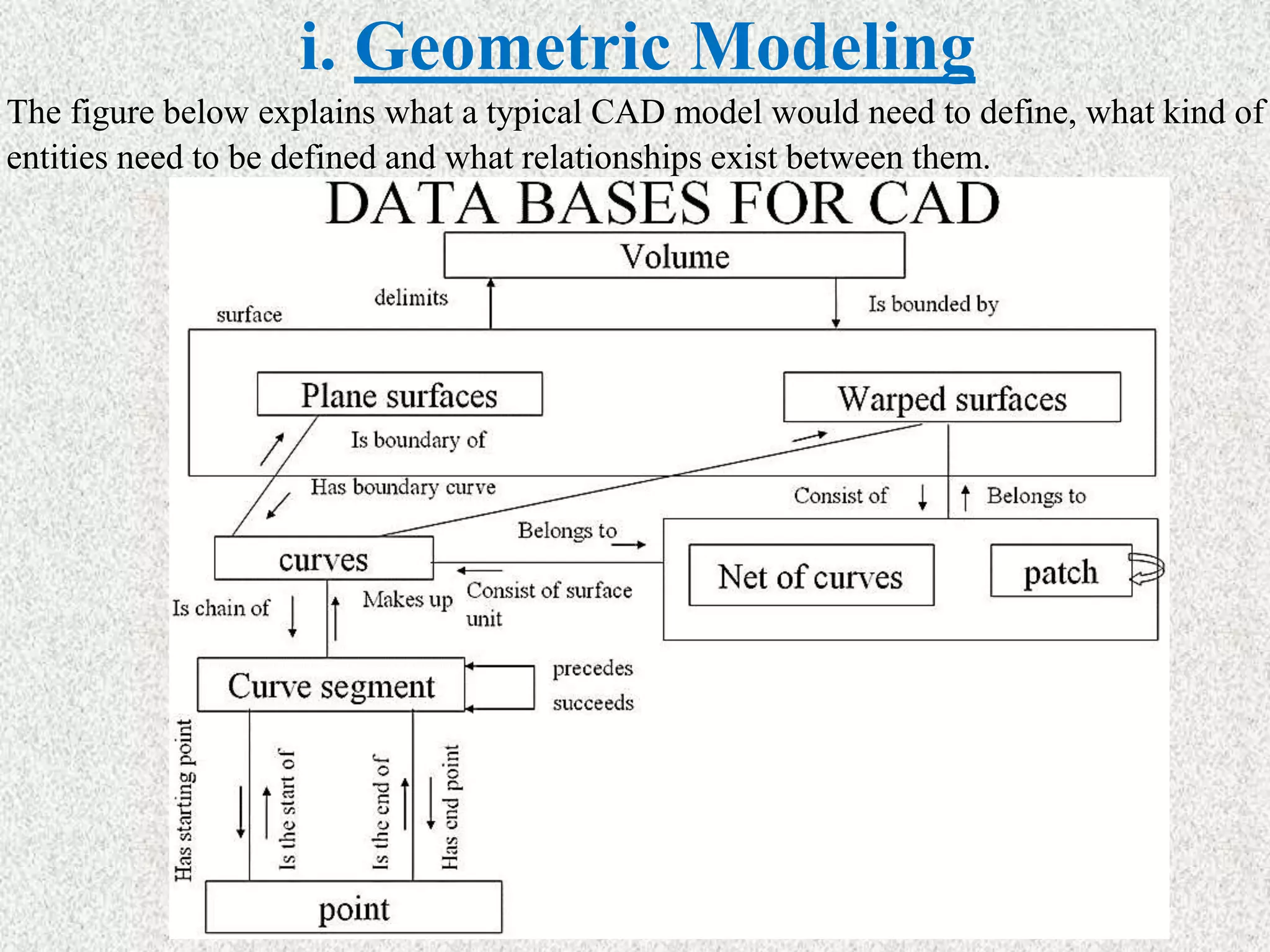

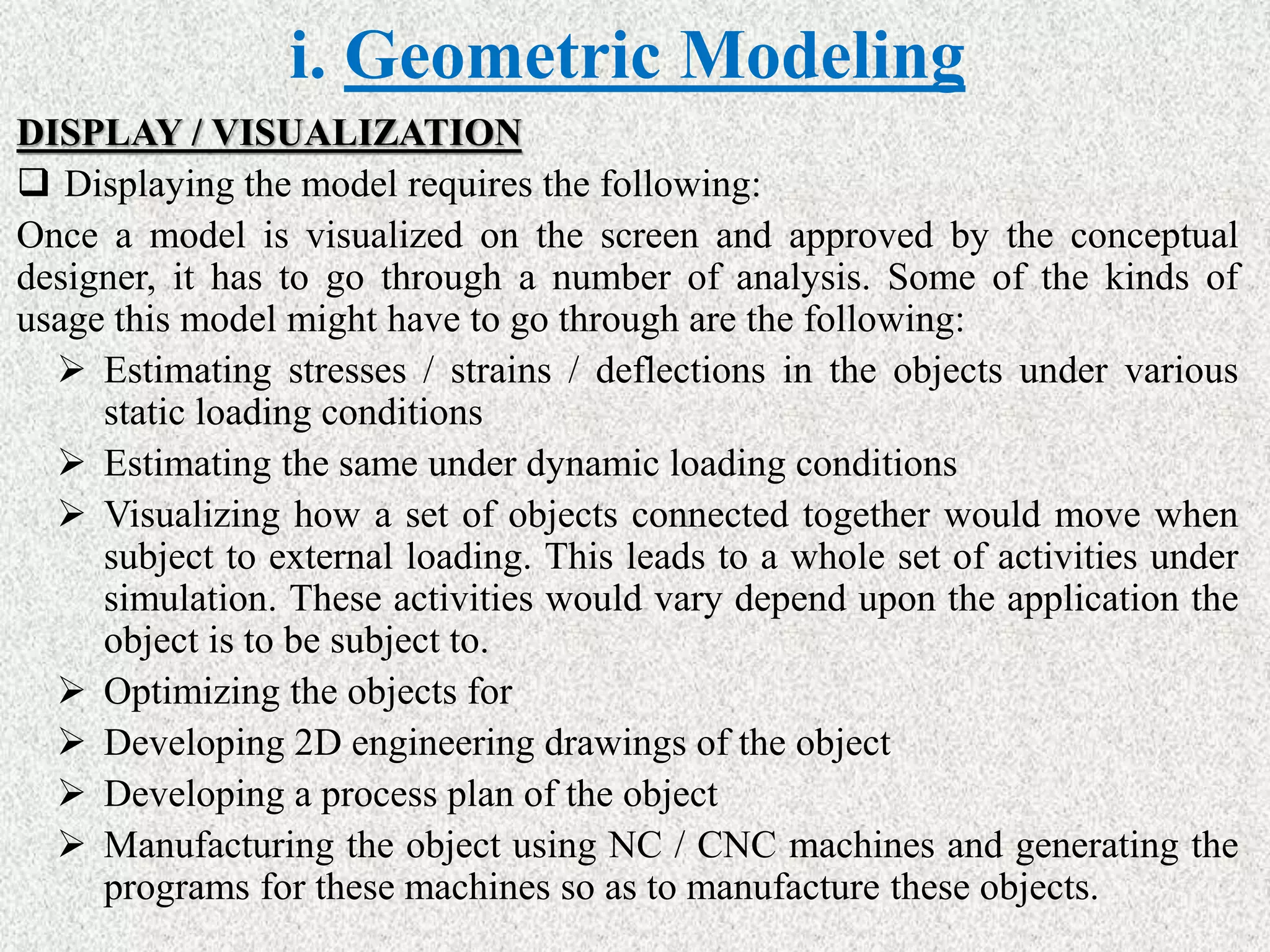

This document provides an overview and introduction to CAD/CAM. It defines CAD as using computers to assist in the design process through computer graphics and software packages. CAD involves creating, modifying, analyzing, or optimizing a design on a computer system using hardware and software. CAM is defined as using computers to control machines and processes during manufacturing. The document outlines the basic concepts of CAD/CAM, the role of computers in design and manufacturing, and the design process from recognizing needs to presenting the final design.