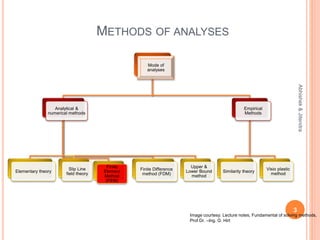

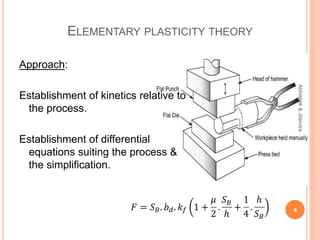

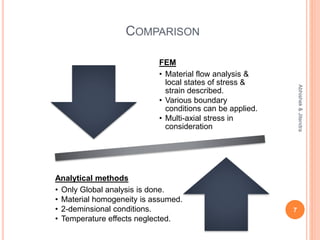

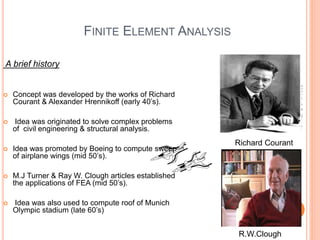

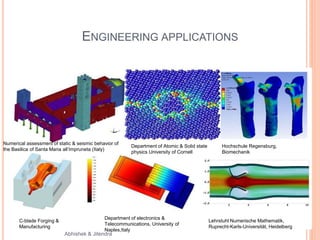

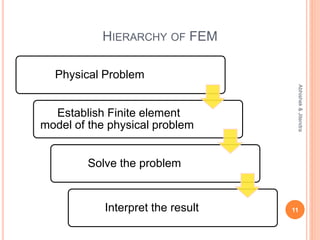

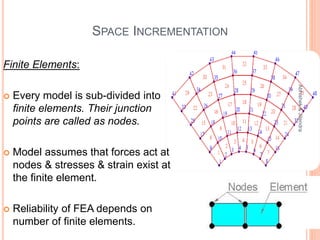

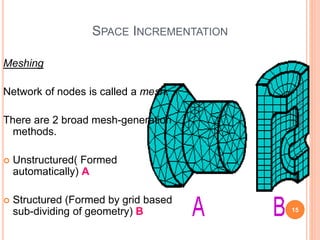

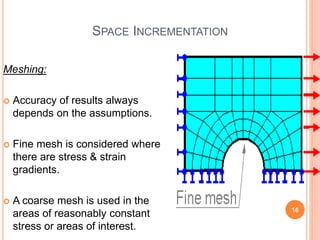

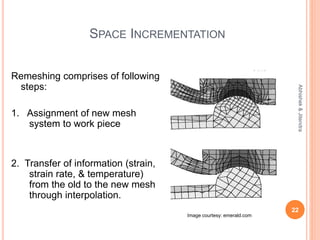

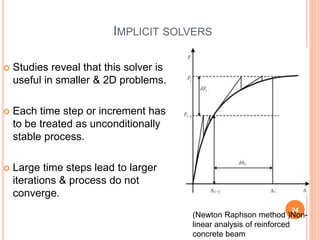

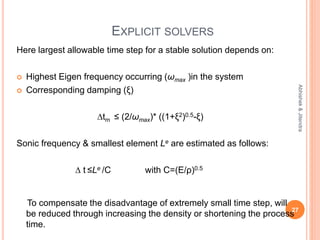

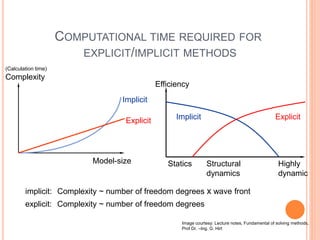

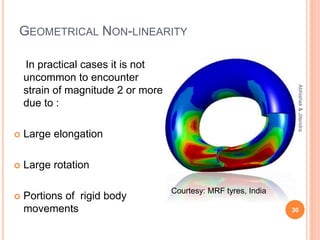

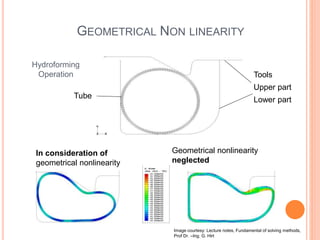

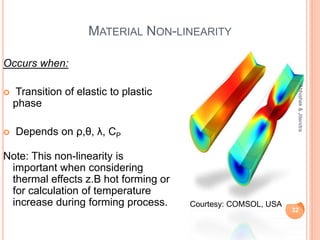

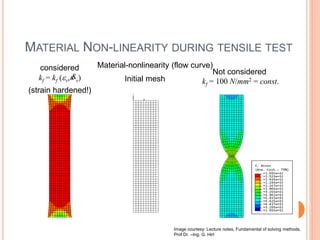

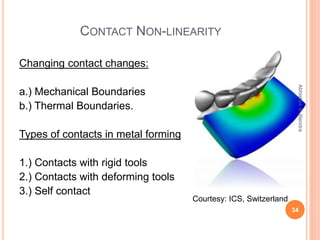

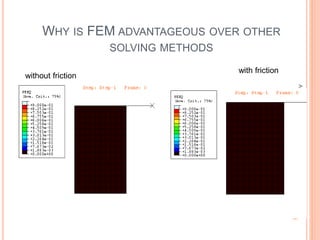

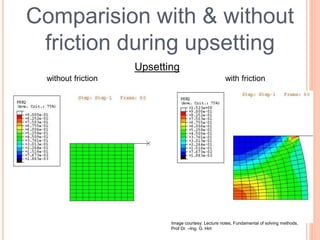

The document discusses various methods of analysis in engineering, particularly focusing on finite element methods (FEM) used for solving complex problems in fields such as metal forming and structural analysis. It outlines the historical development of FEM, its applications, and different types of solvers used, including implicit and explicit methods. Additionally, it covers the assumptions made in these analyses and the non-linearities that may be encountered during simulations.