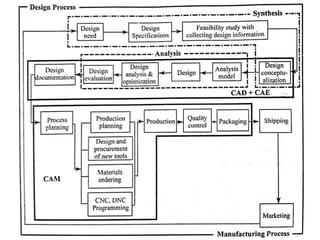

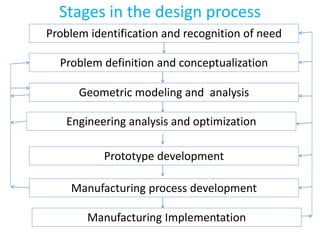

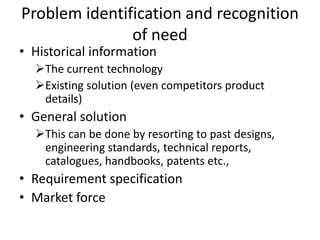

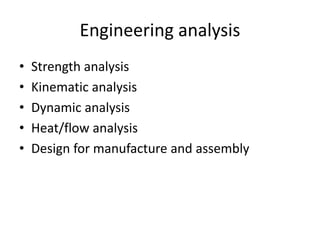

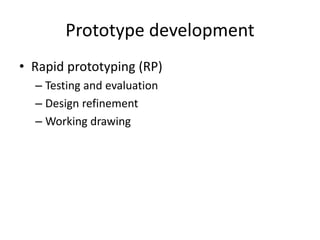

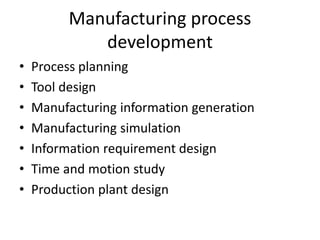

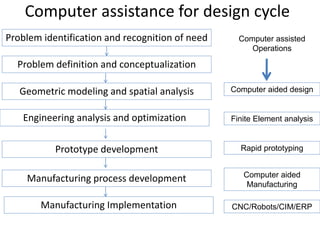

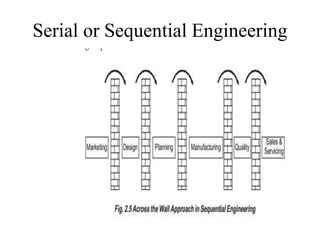

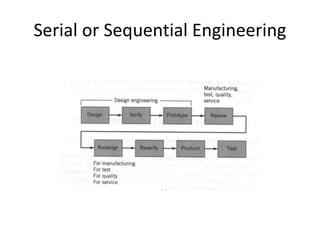

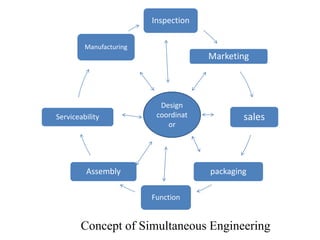

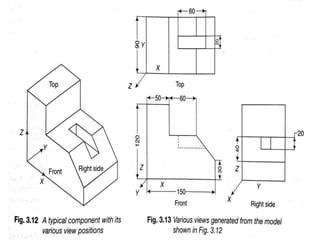

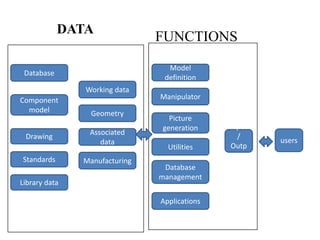

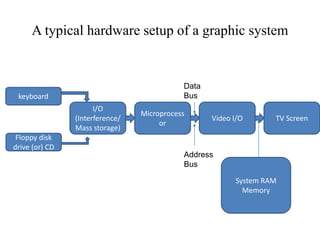

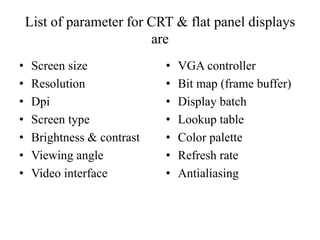

The document outlines the fundamentals of computer-aided design (CAD) and manufacturing (CAM), detailing the product life cycle, design and manufacturing processes, and the technology used in CAD systems. It emphasizes the importance of geometric modeling, concurrent engineering, and various computer graphics principles relevant to design. Additionally, it discusses the advantages of CAD and how it enhances accuracy and efficiency throughout the design and manufacturing stages.