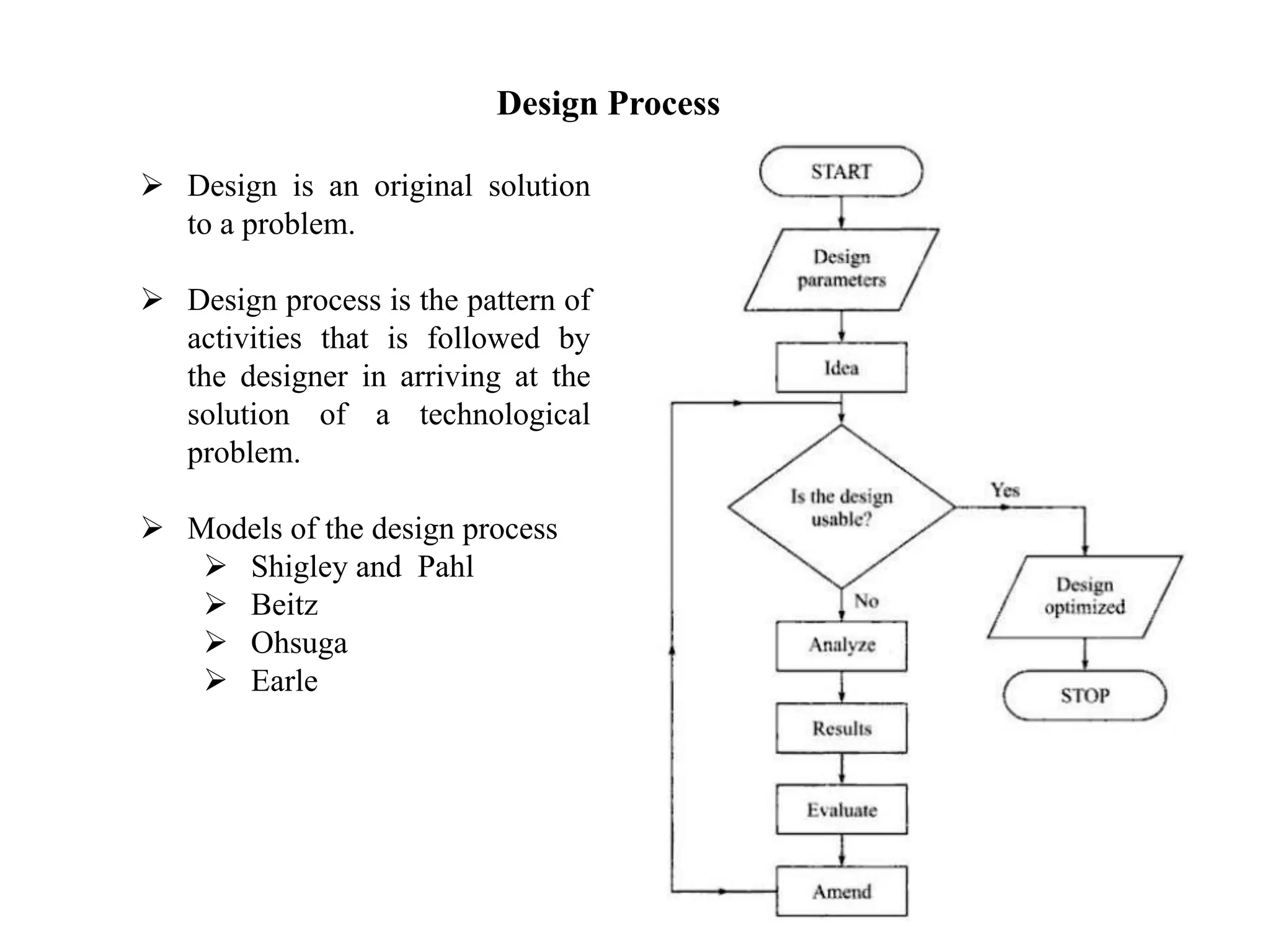

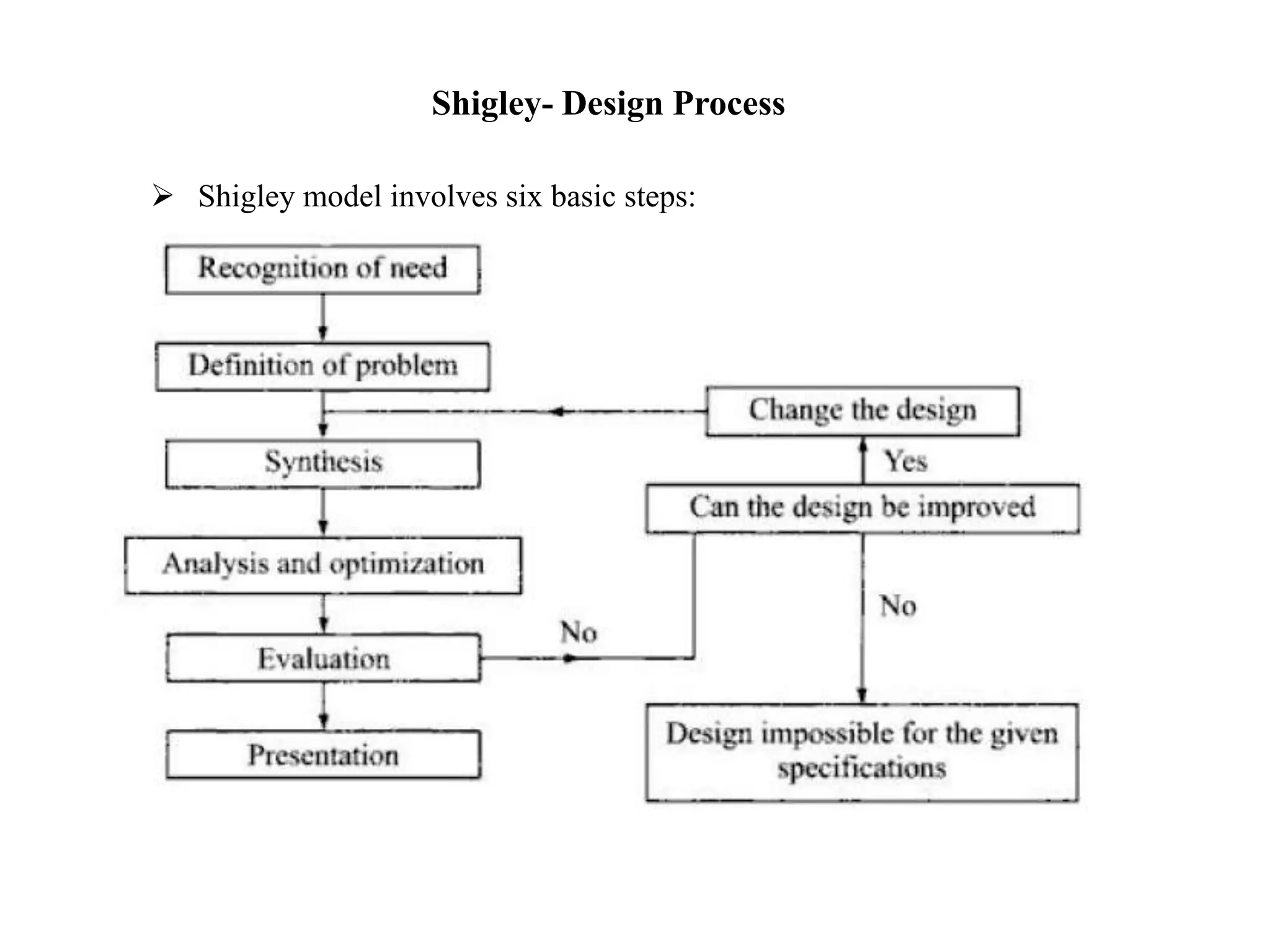

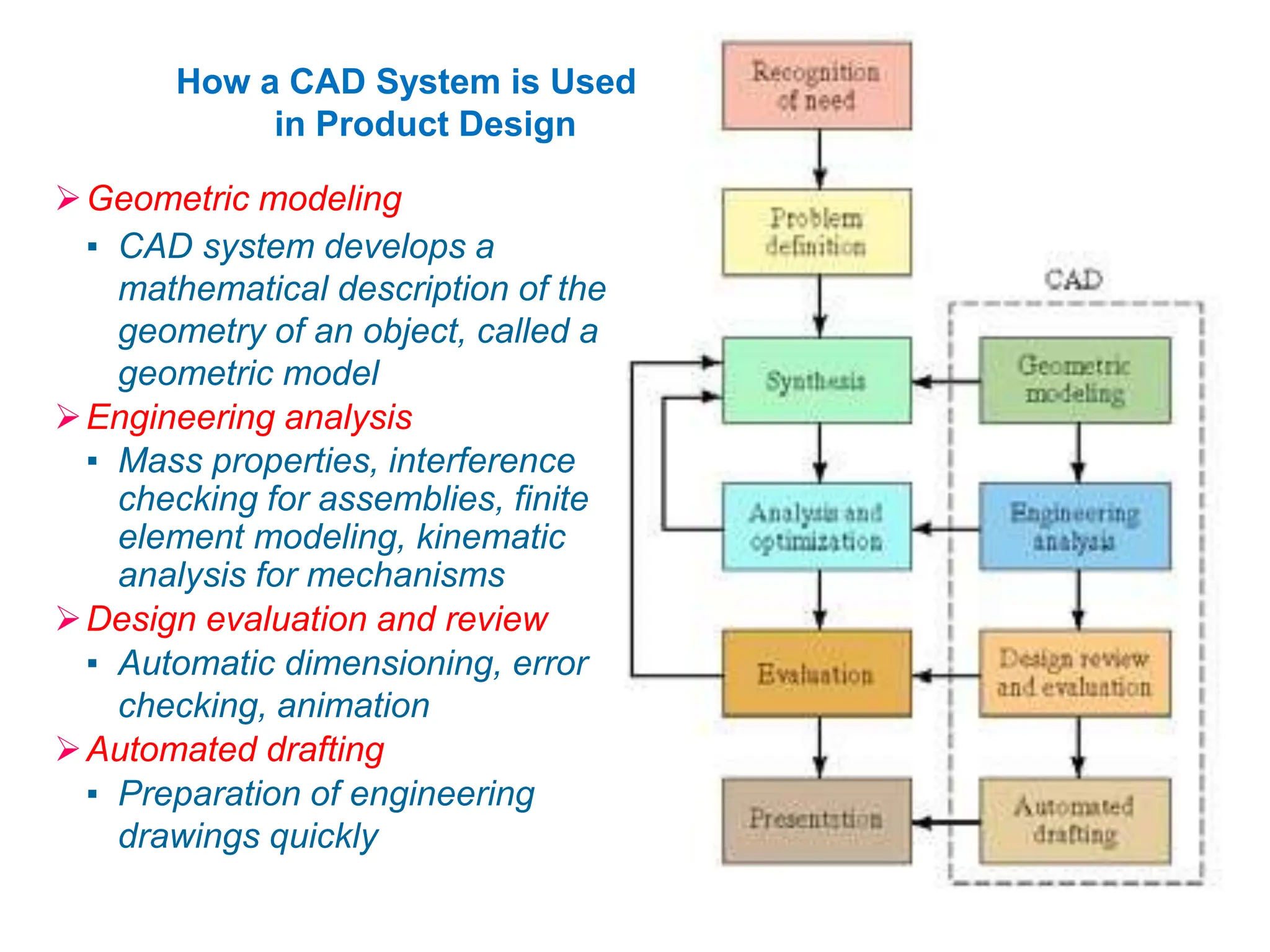

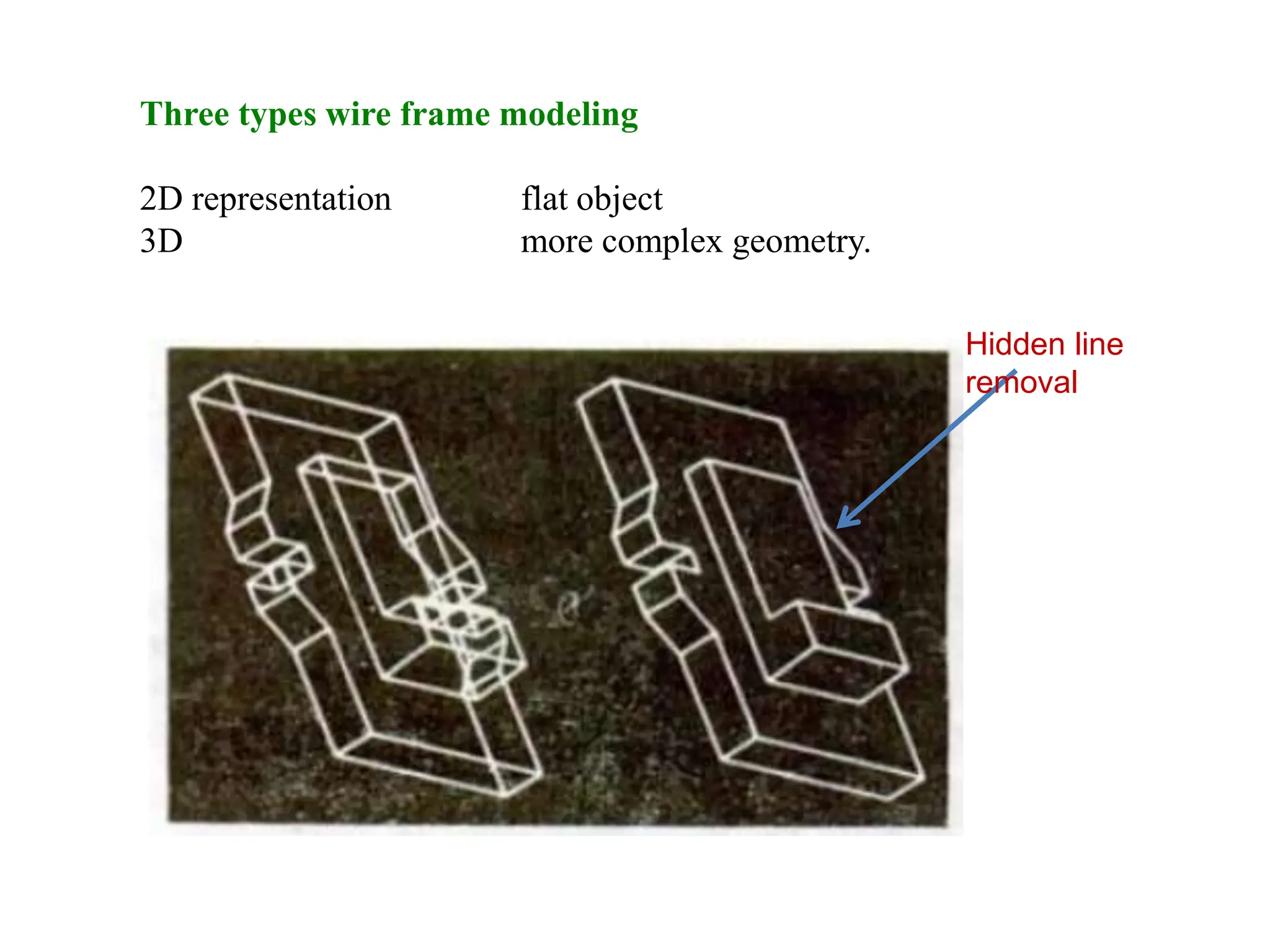

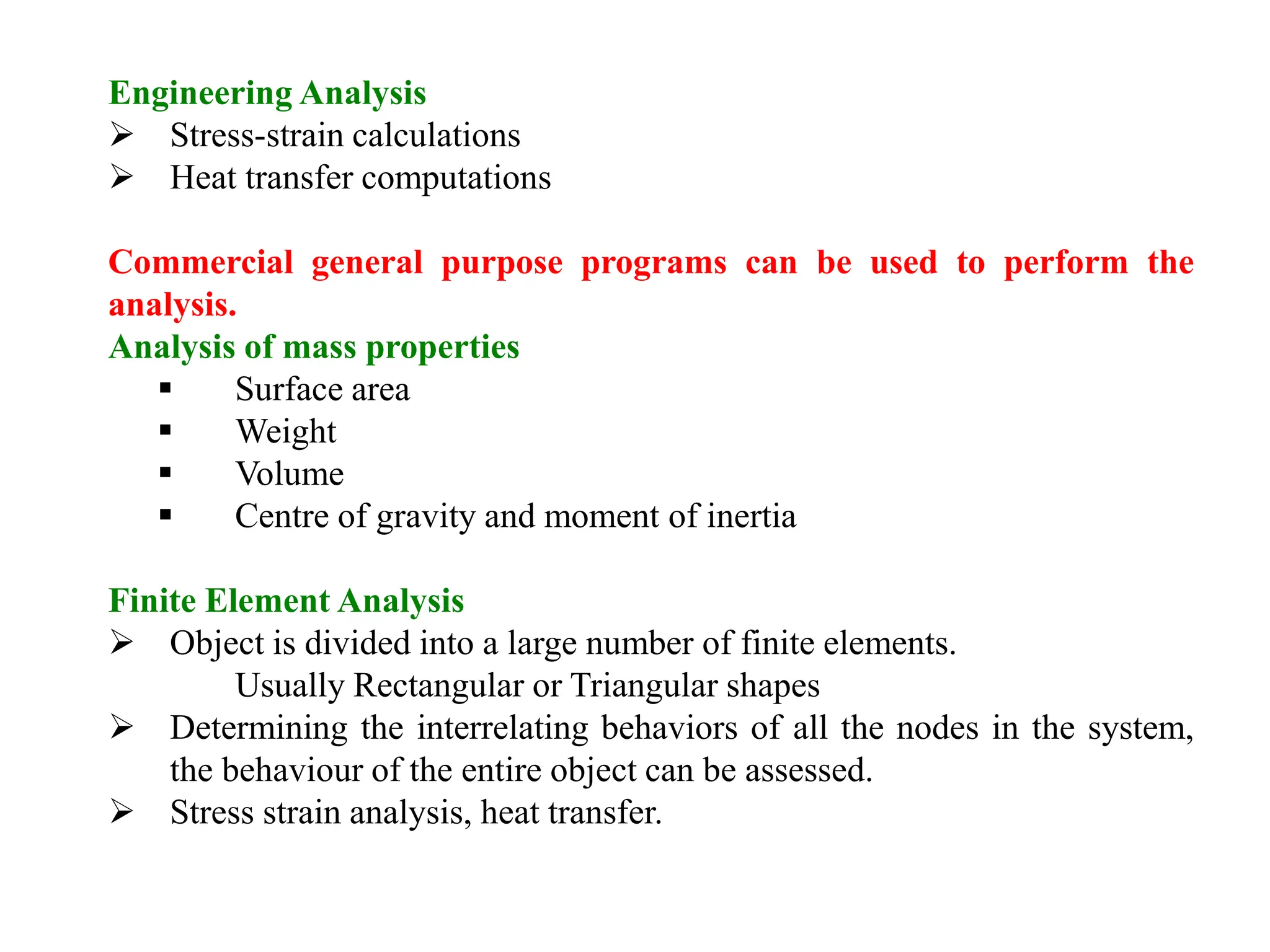

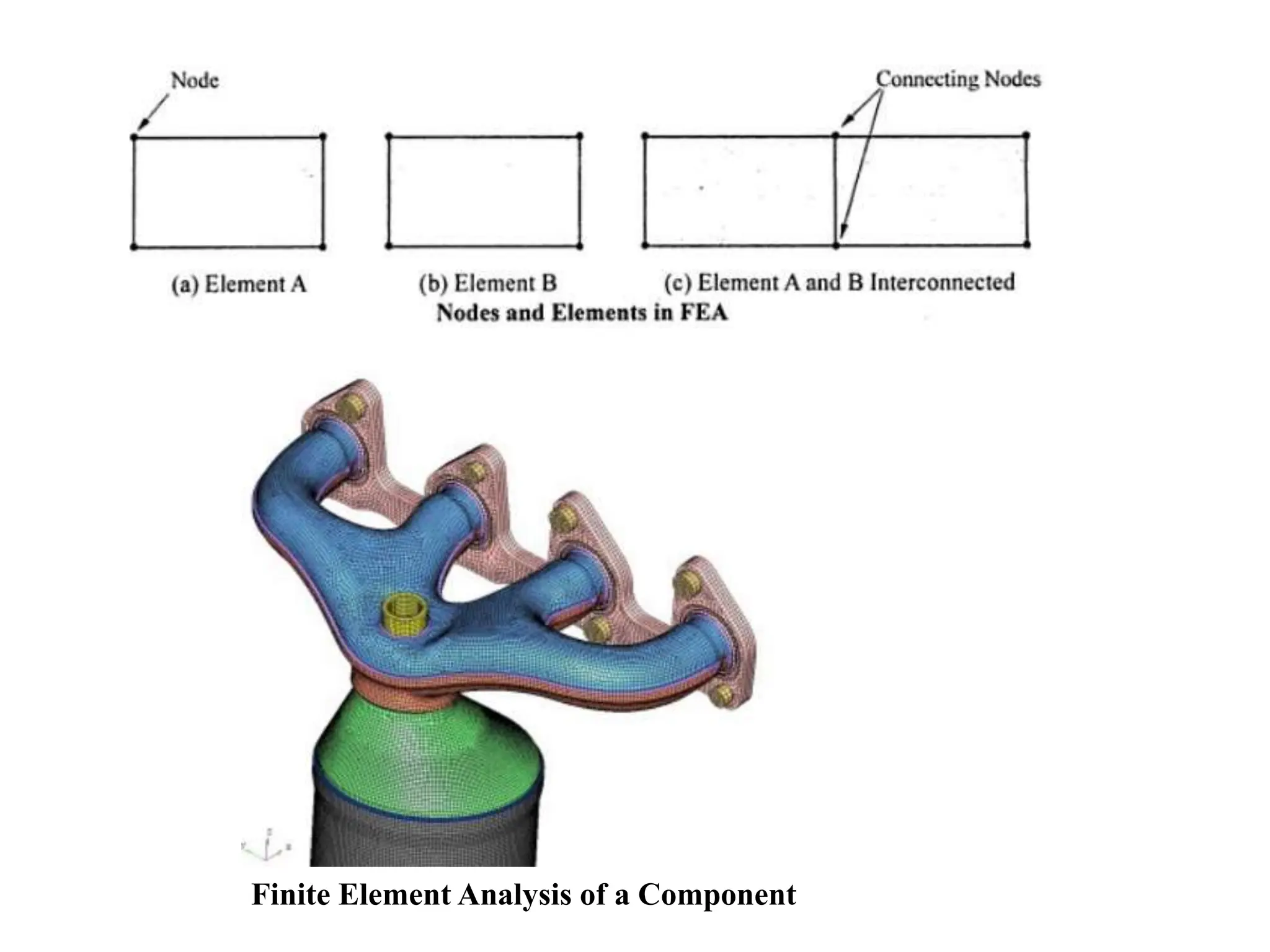

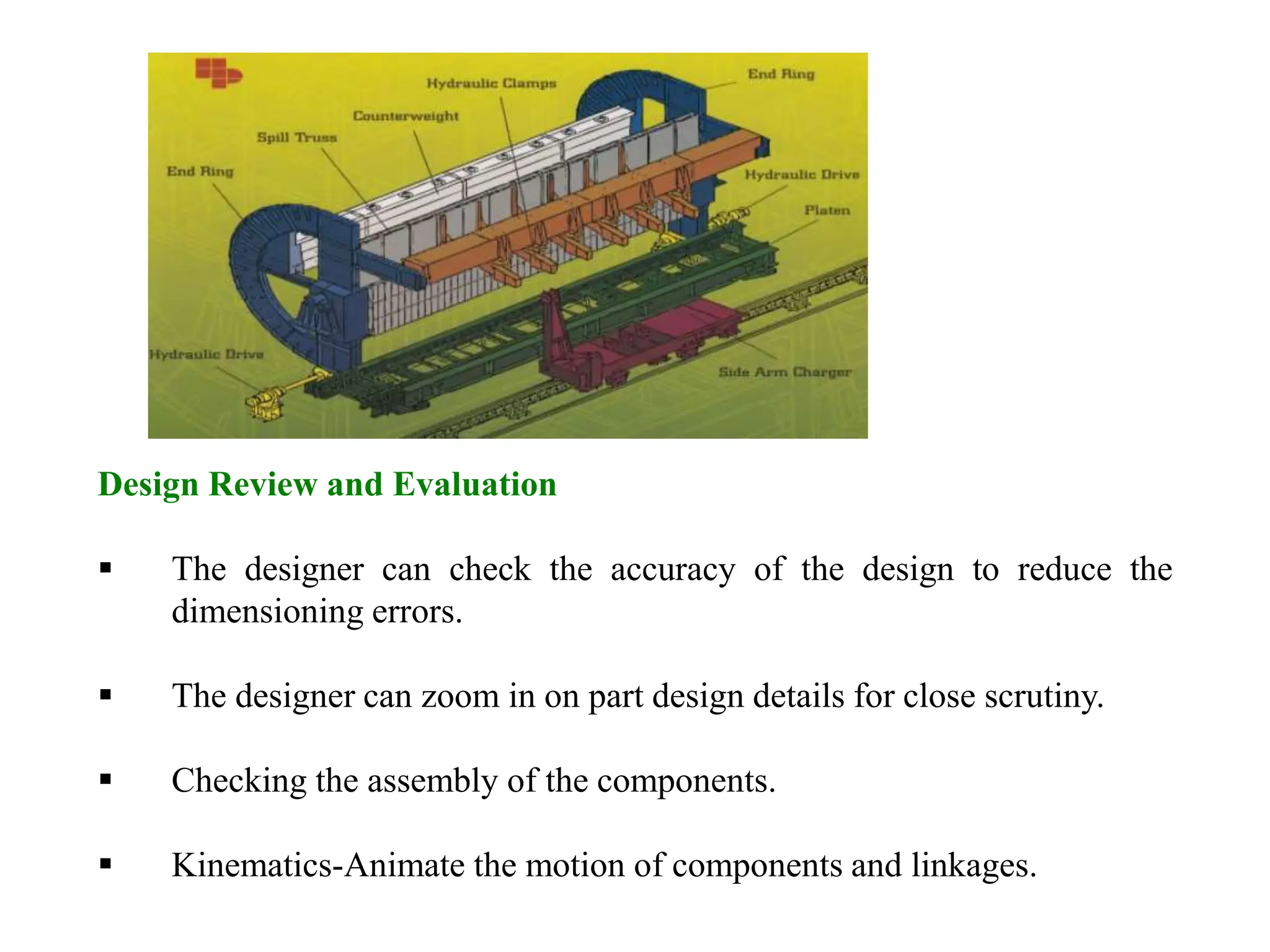

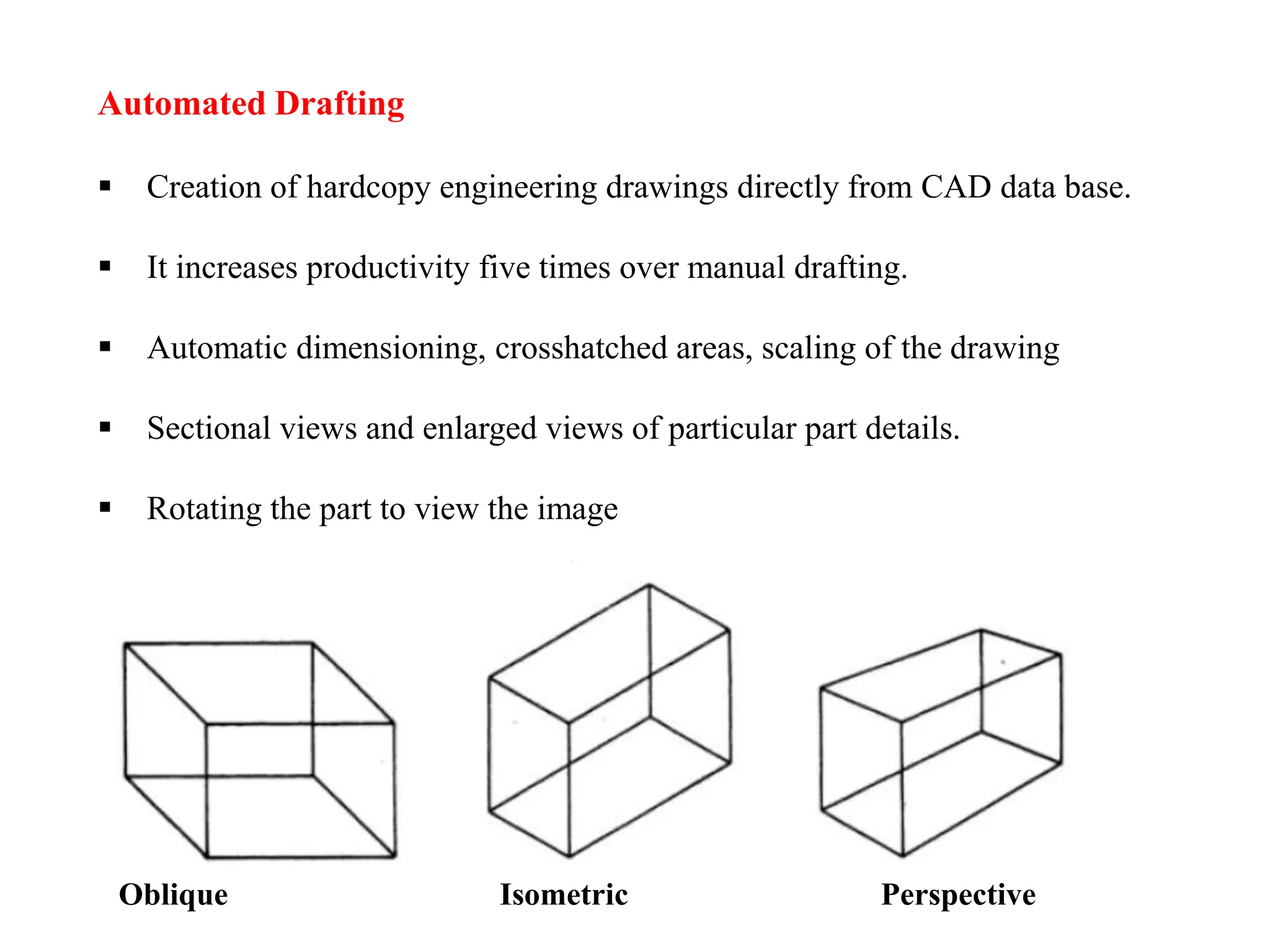

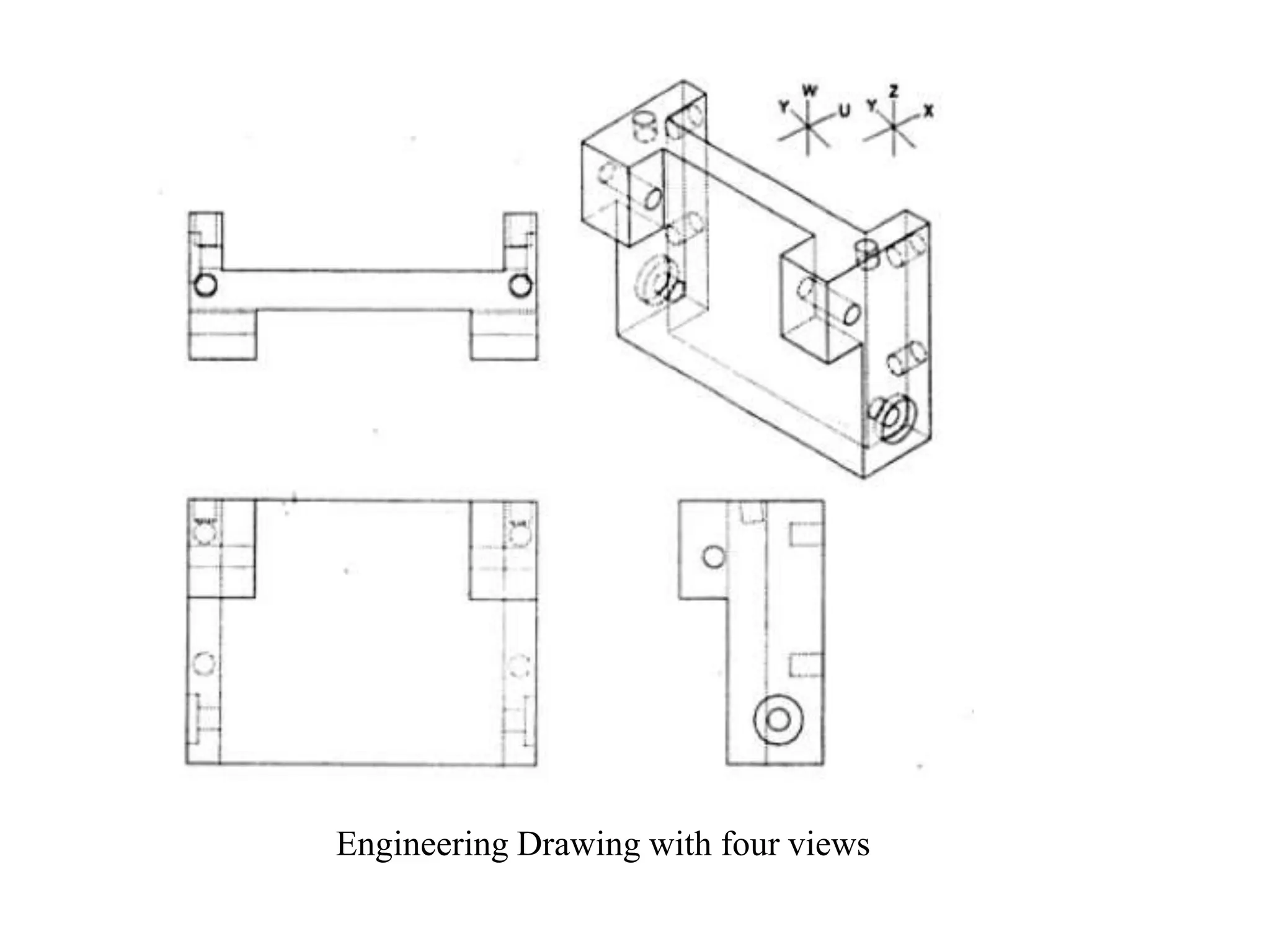

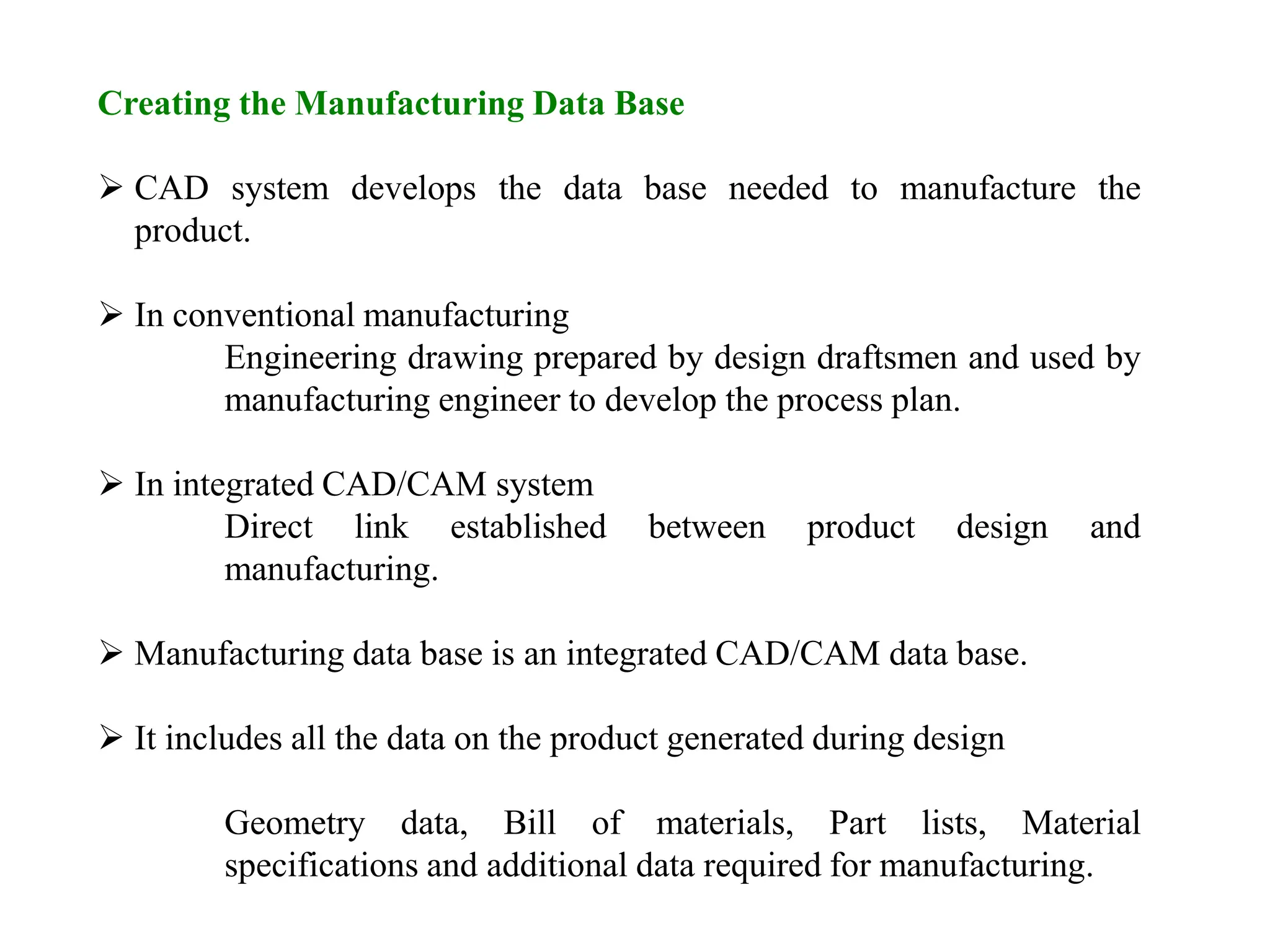

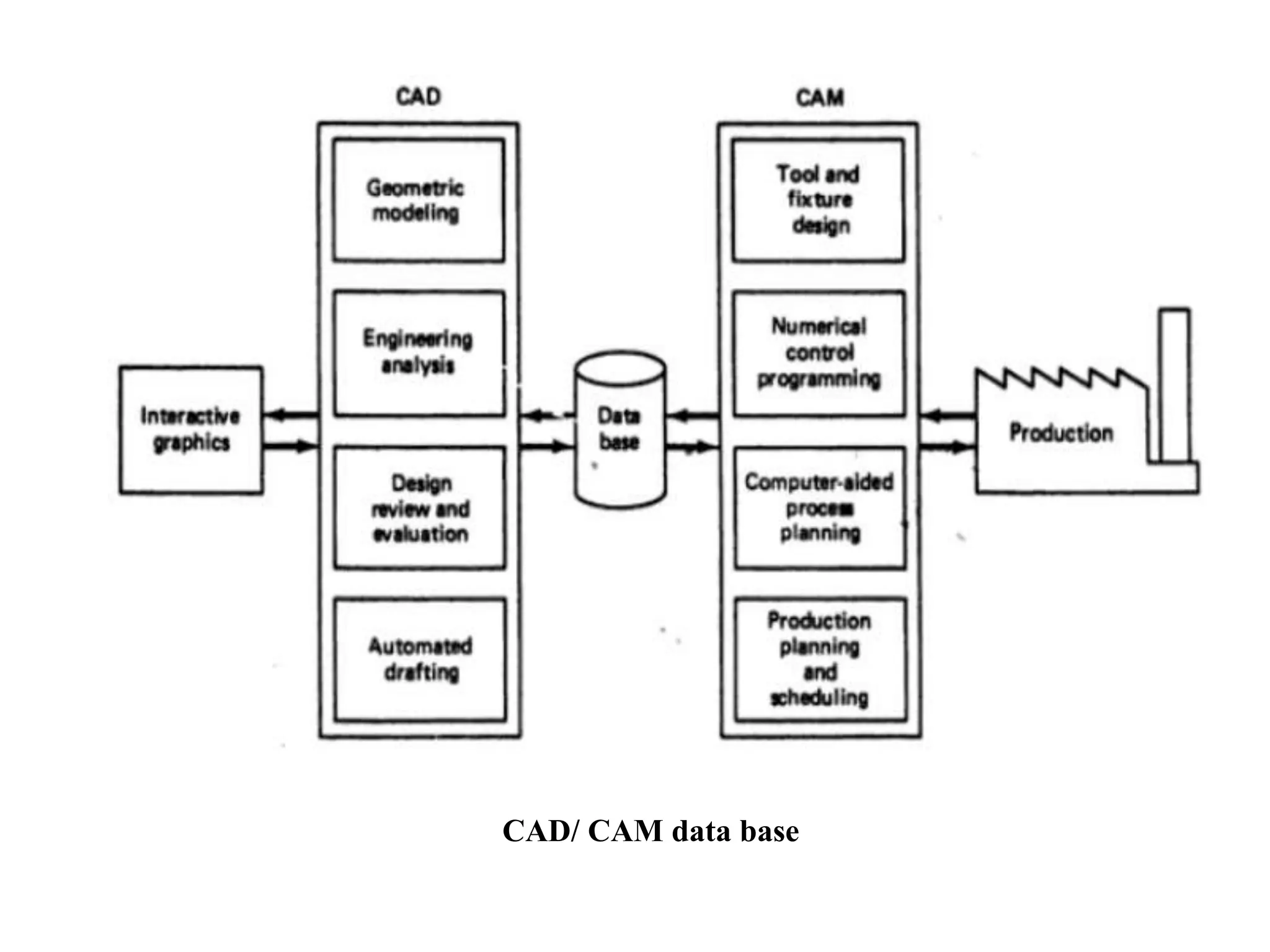

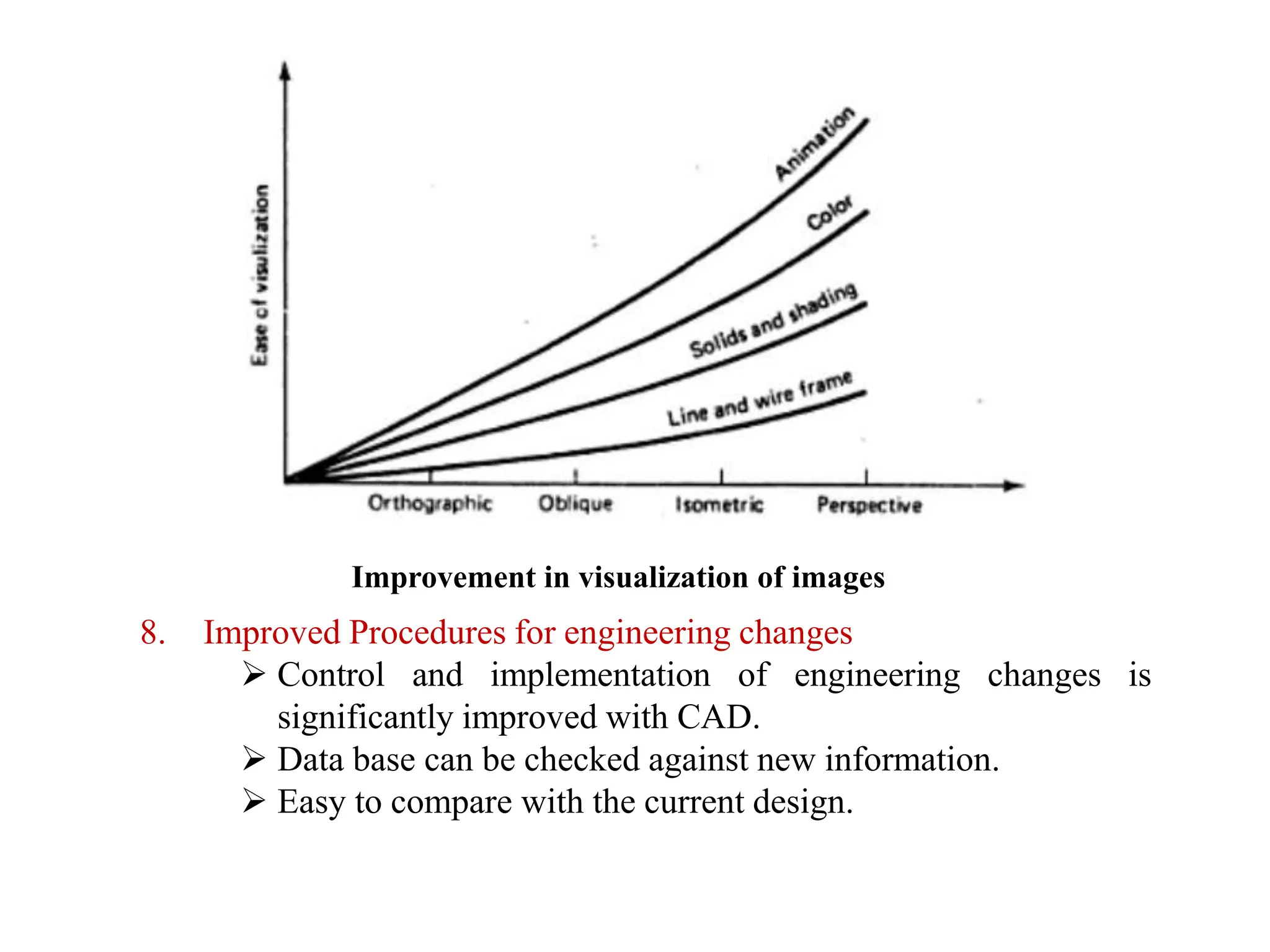

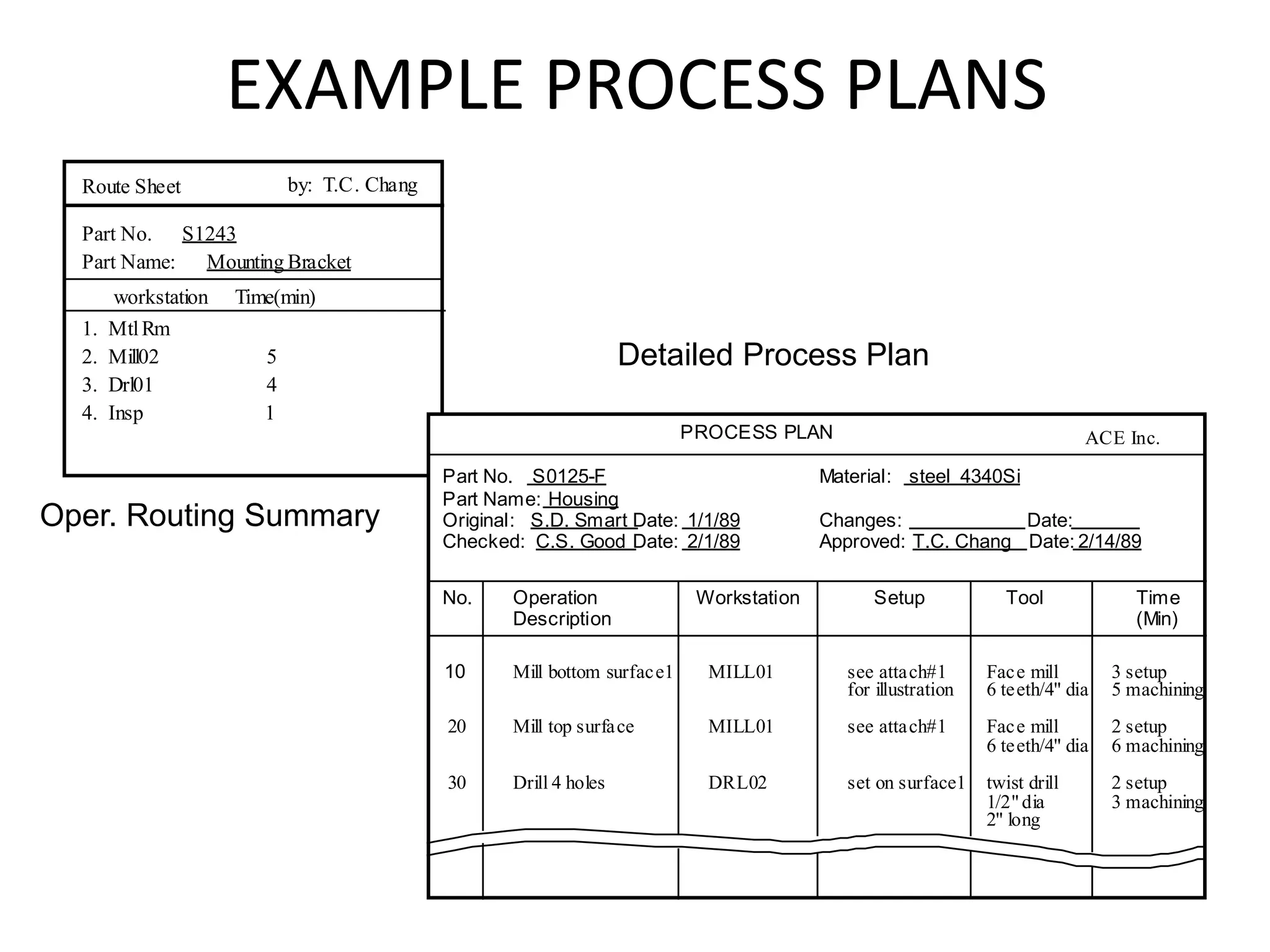

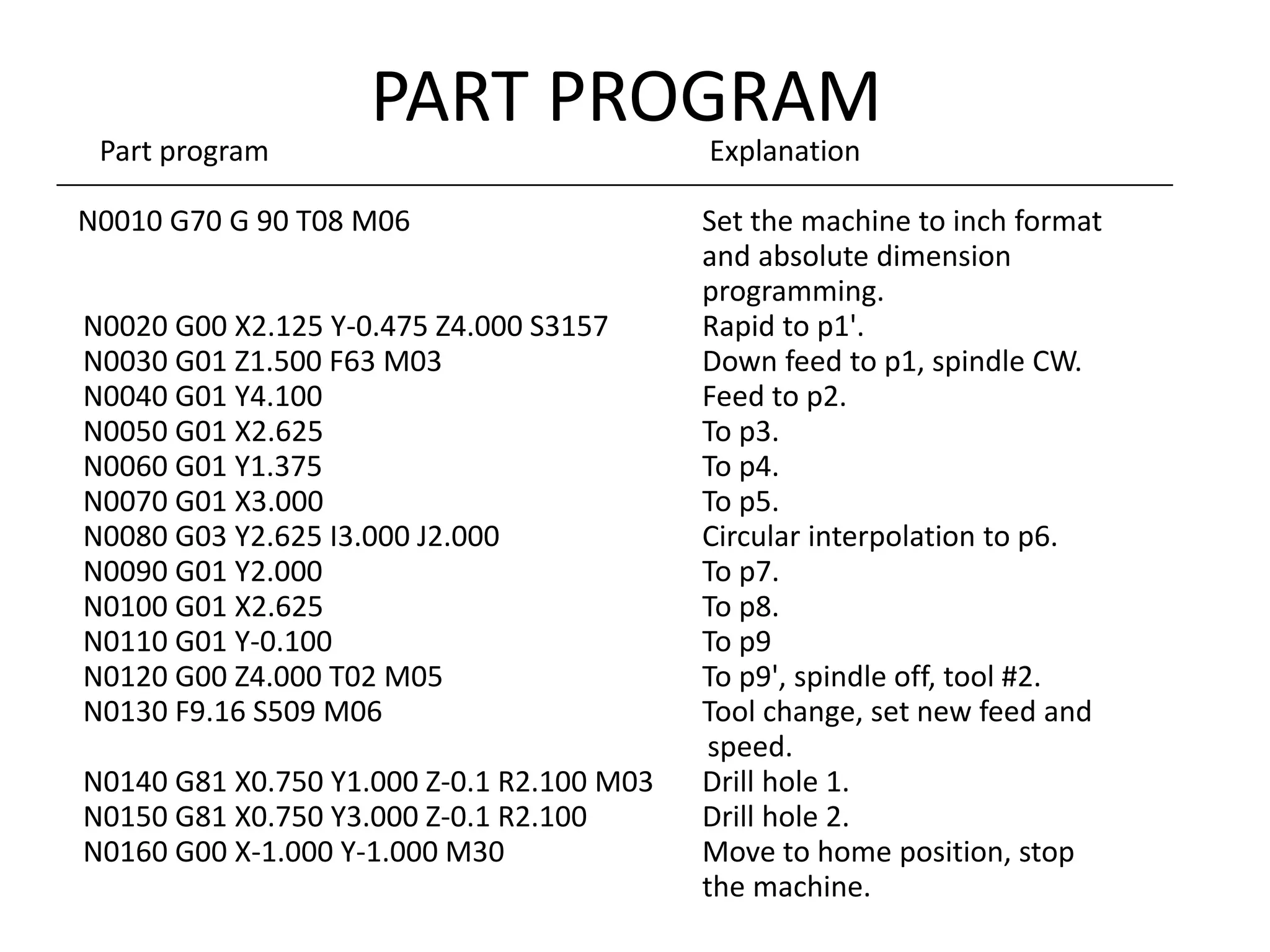

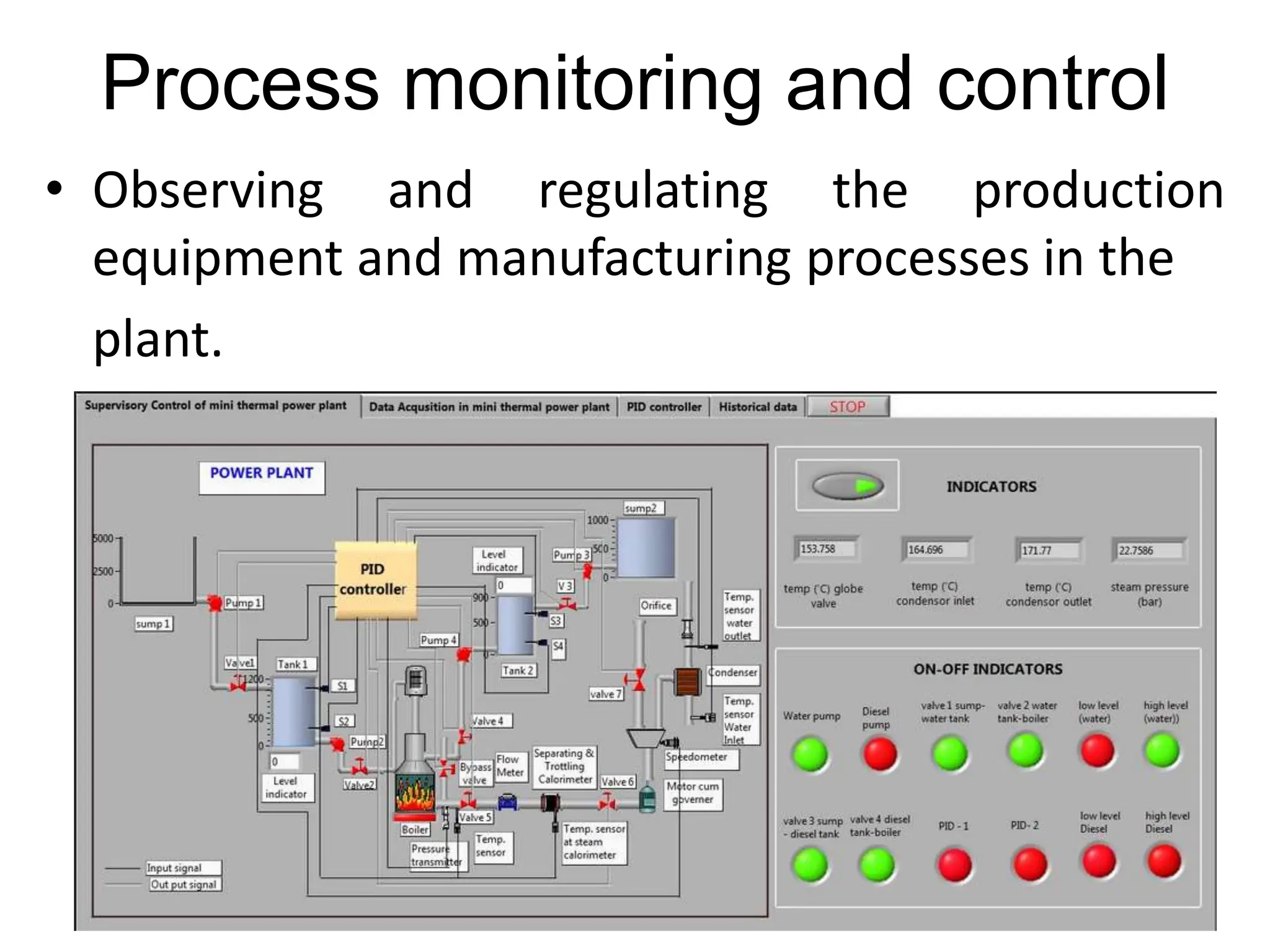

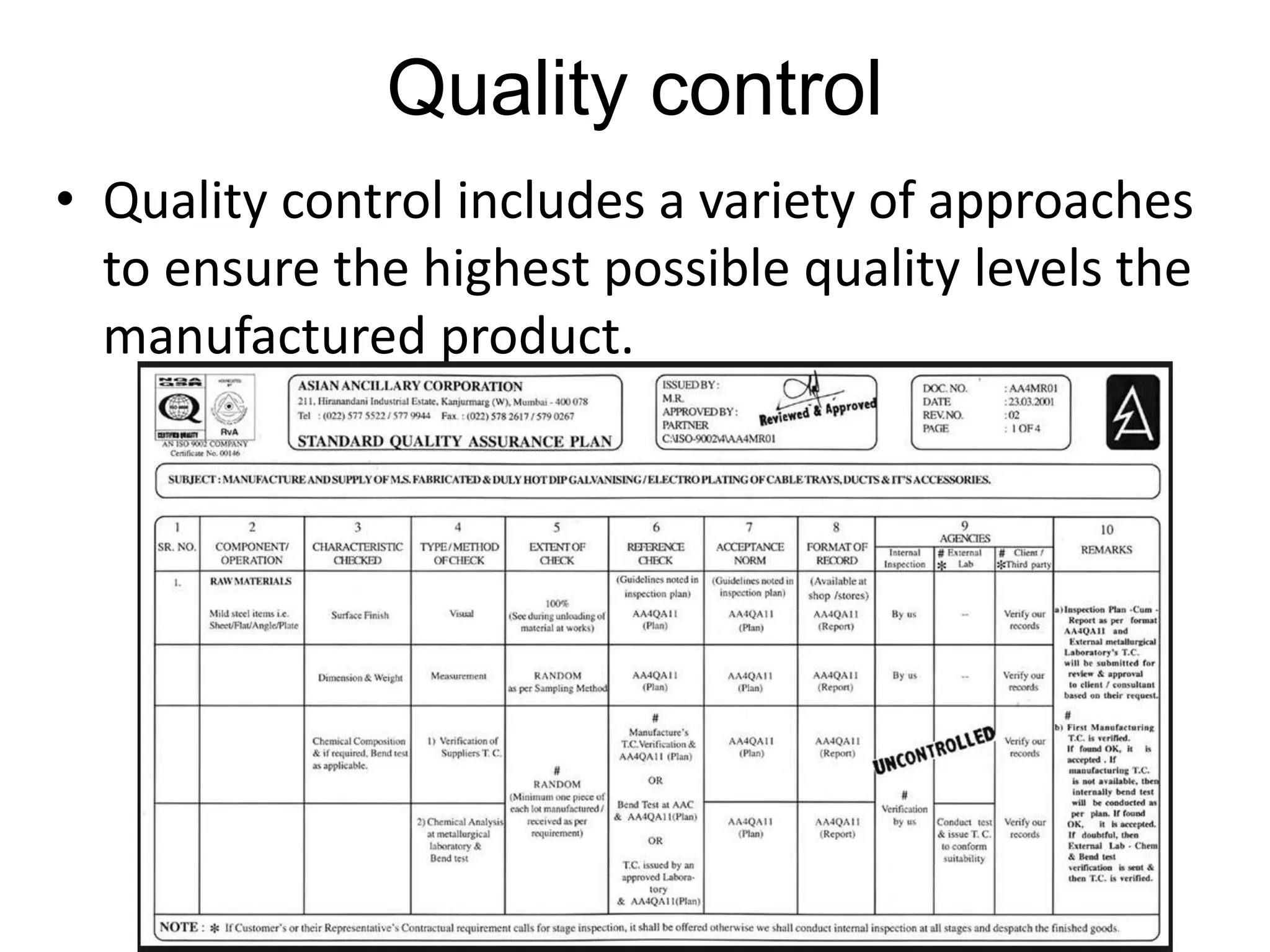

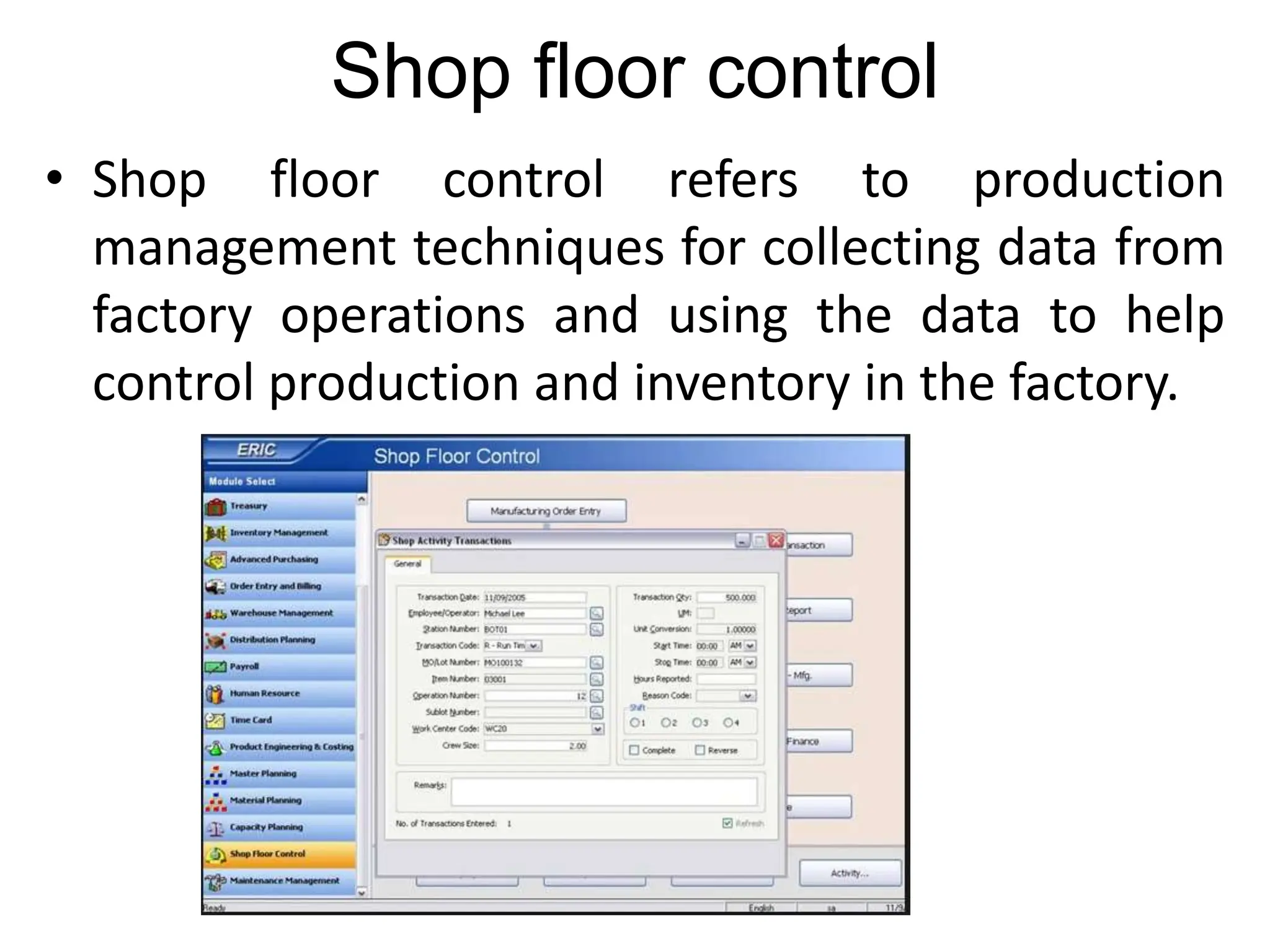

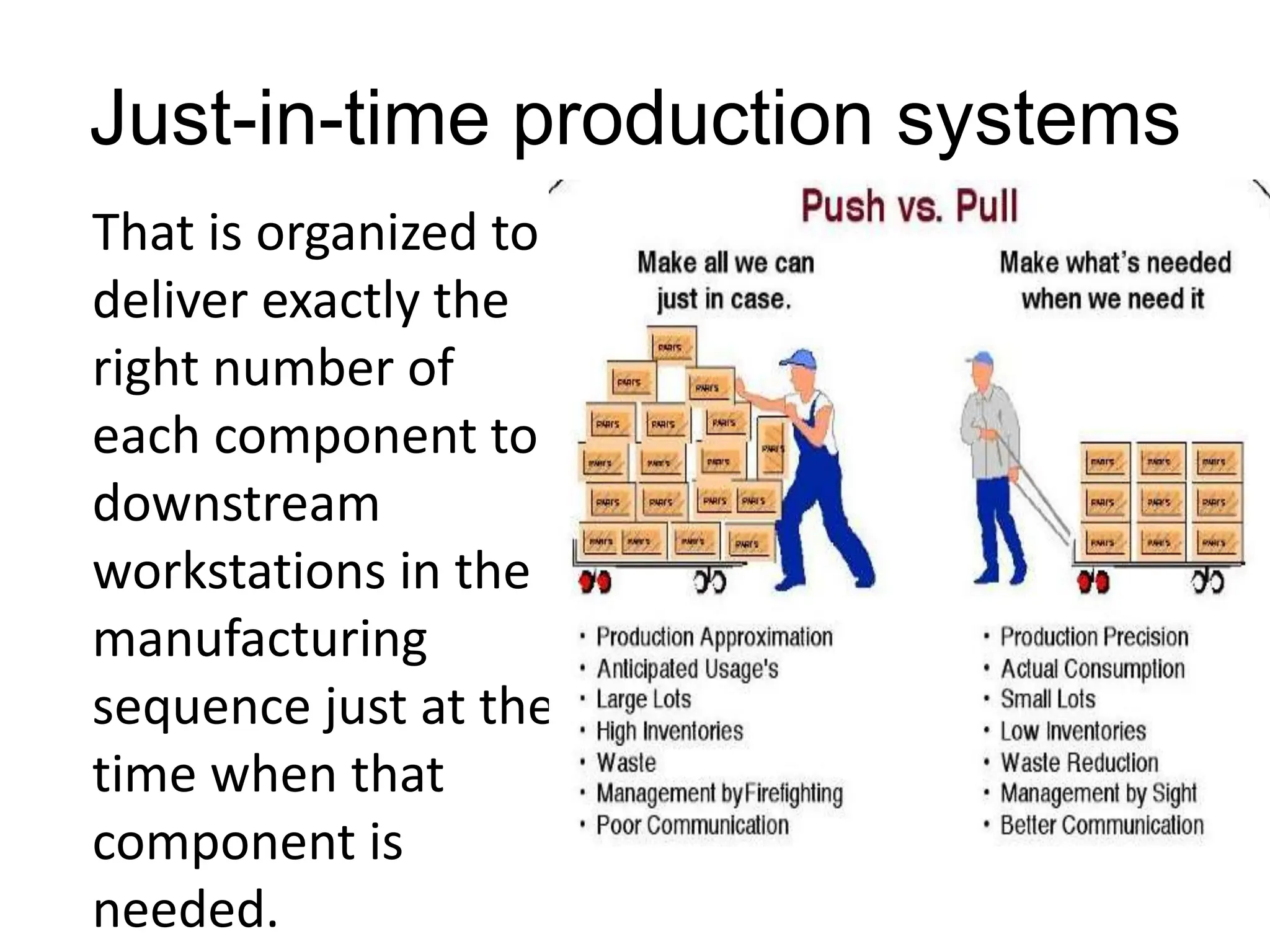

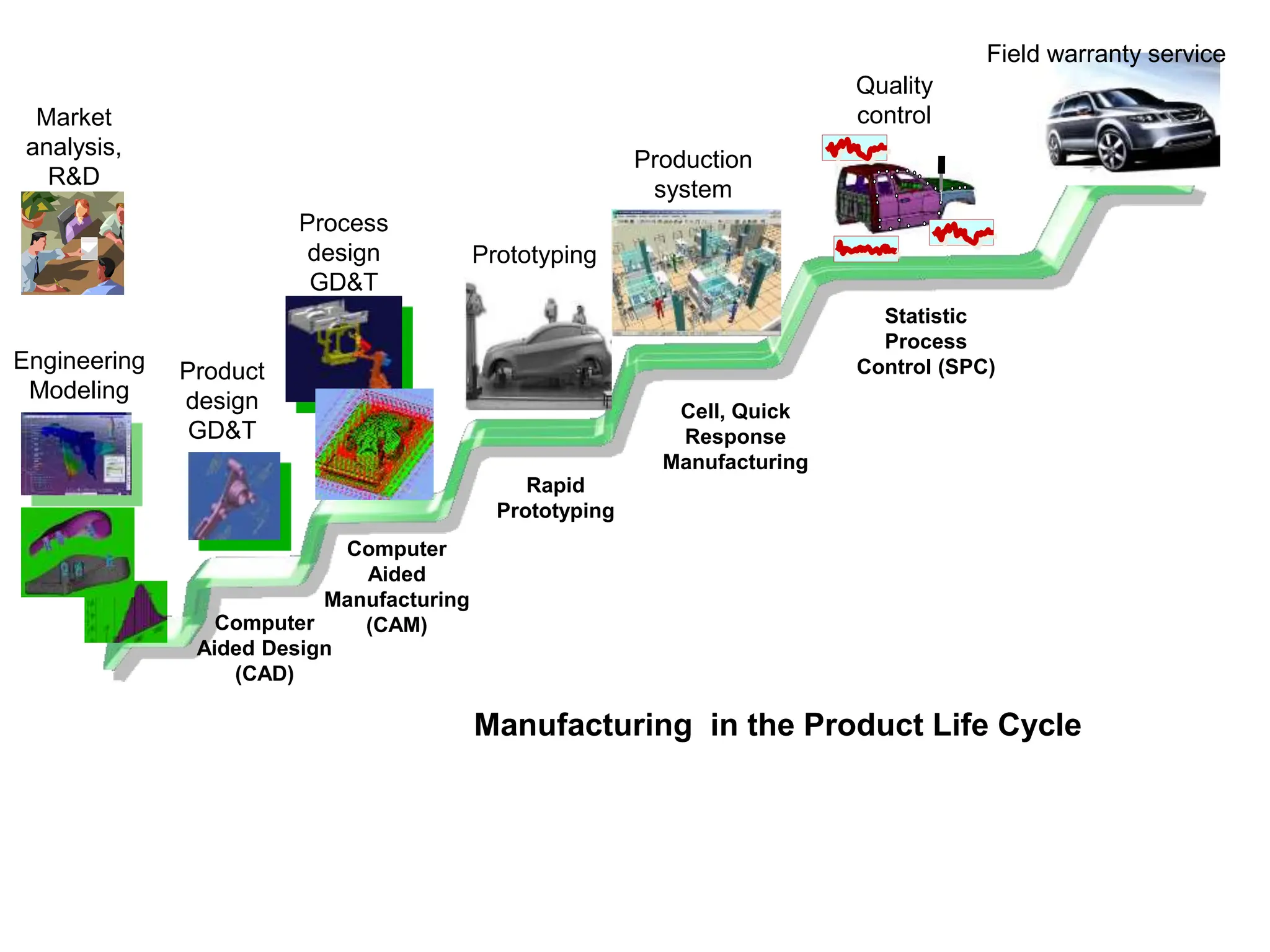

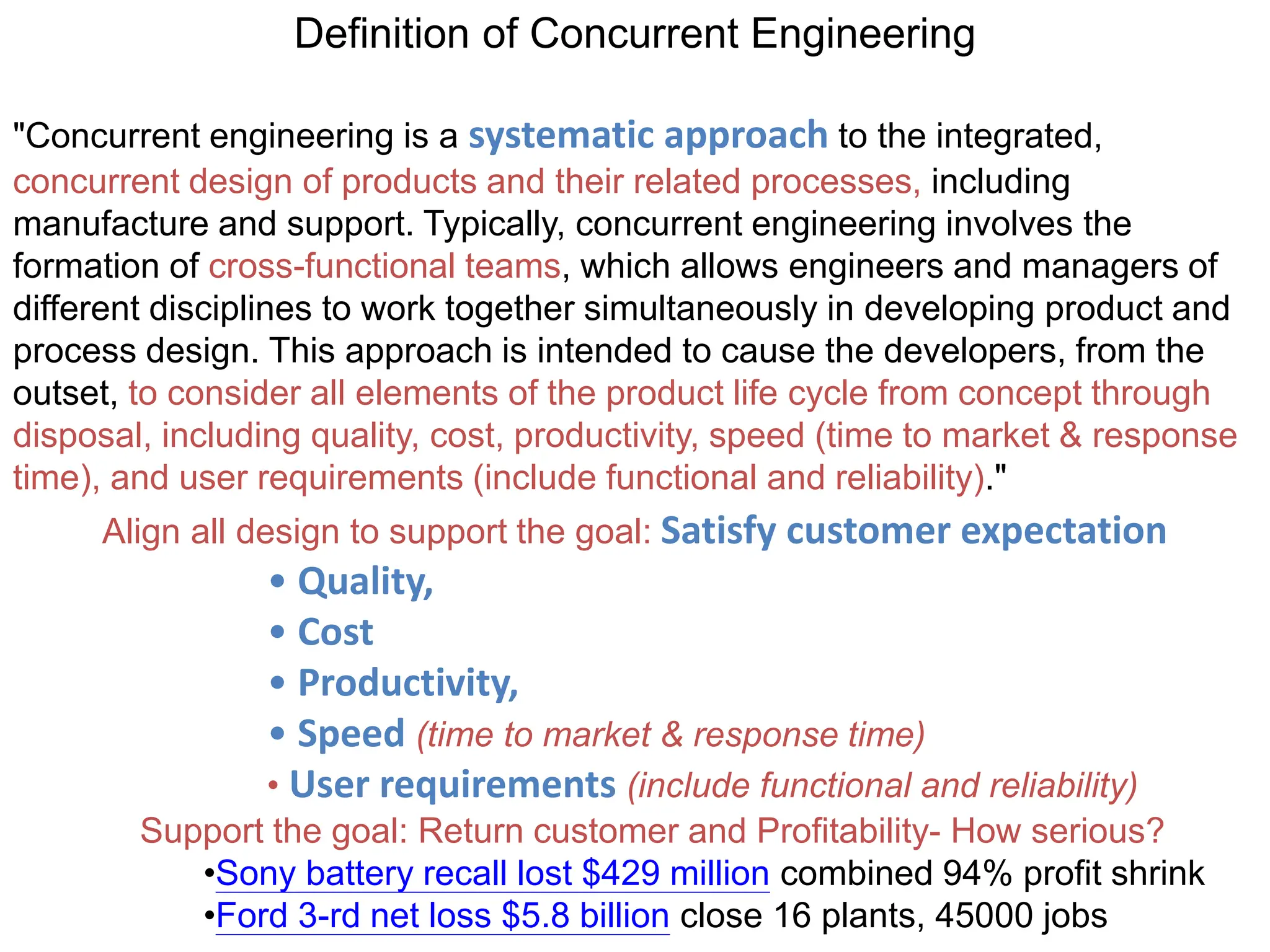

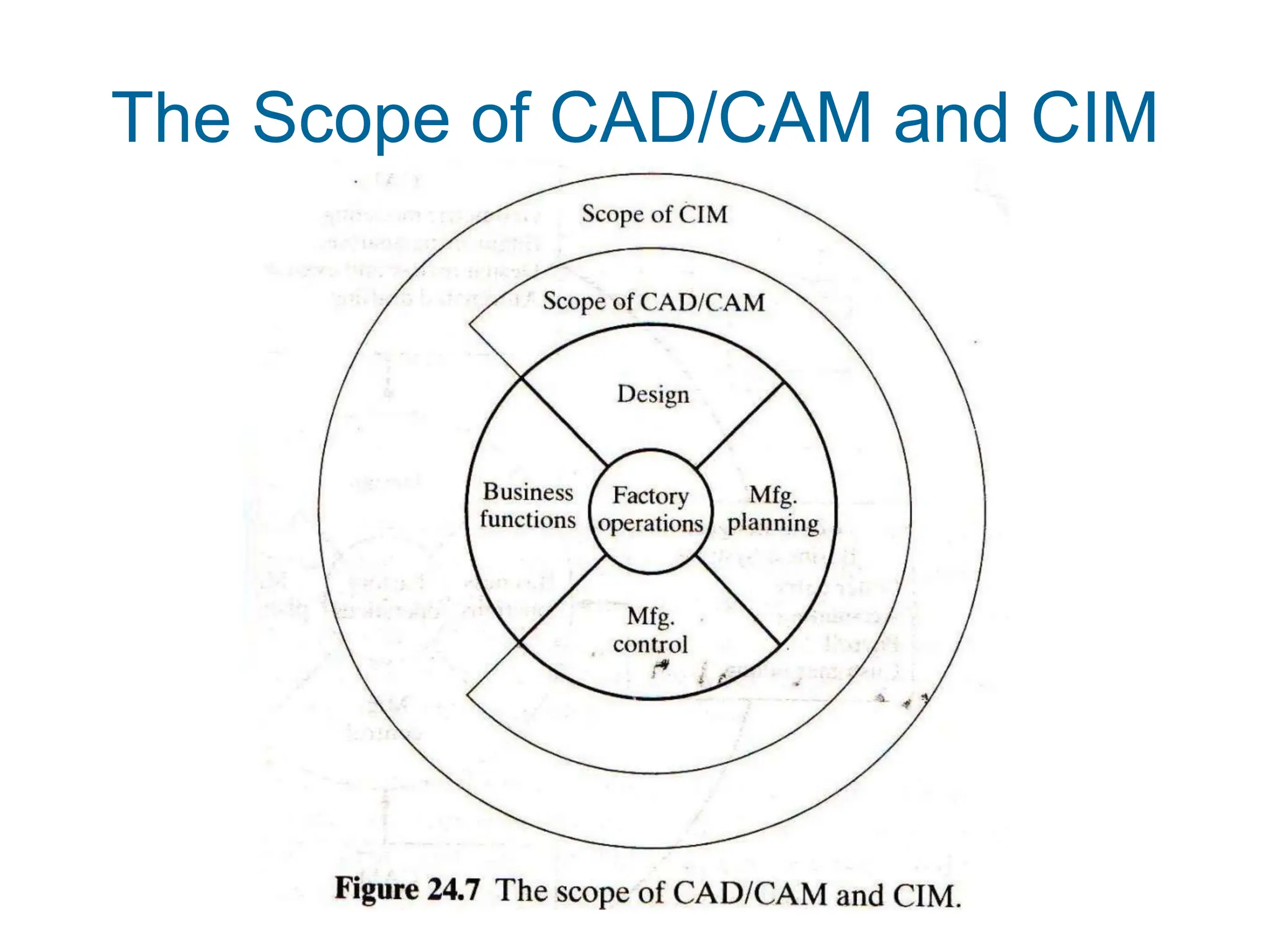

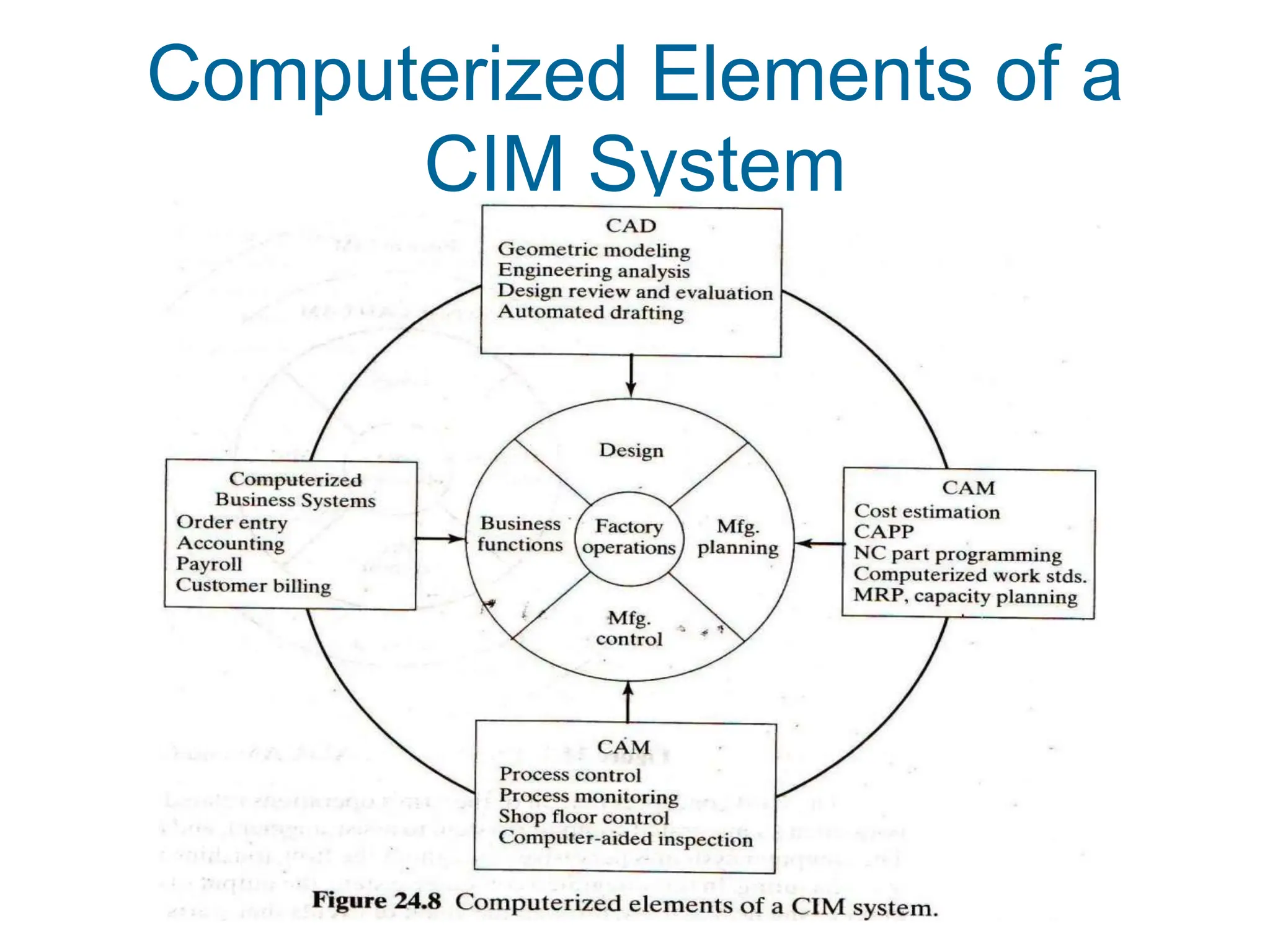

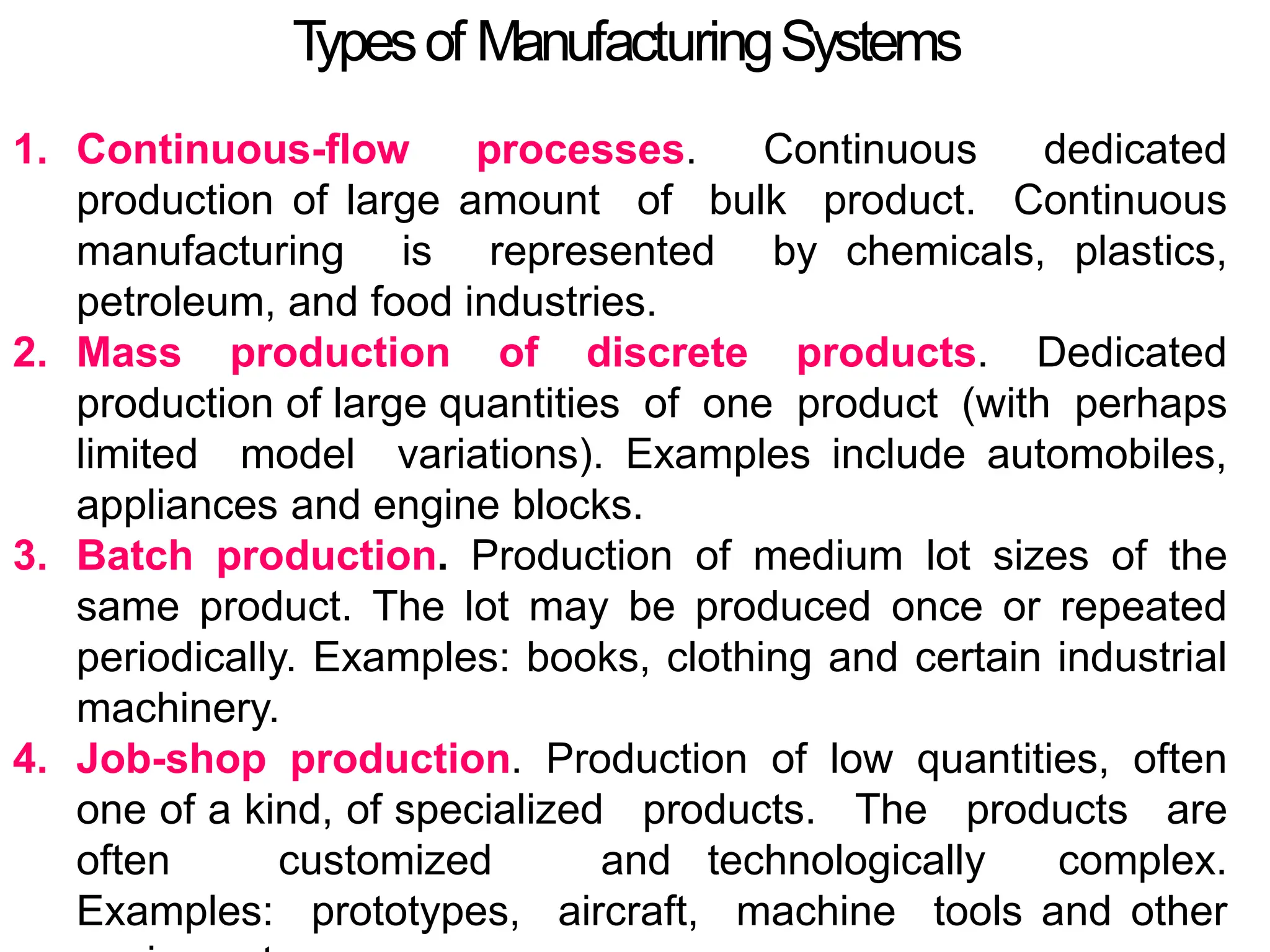

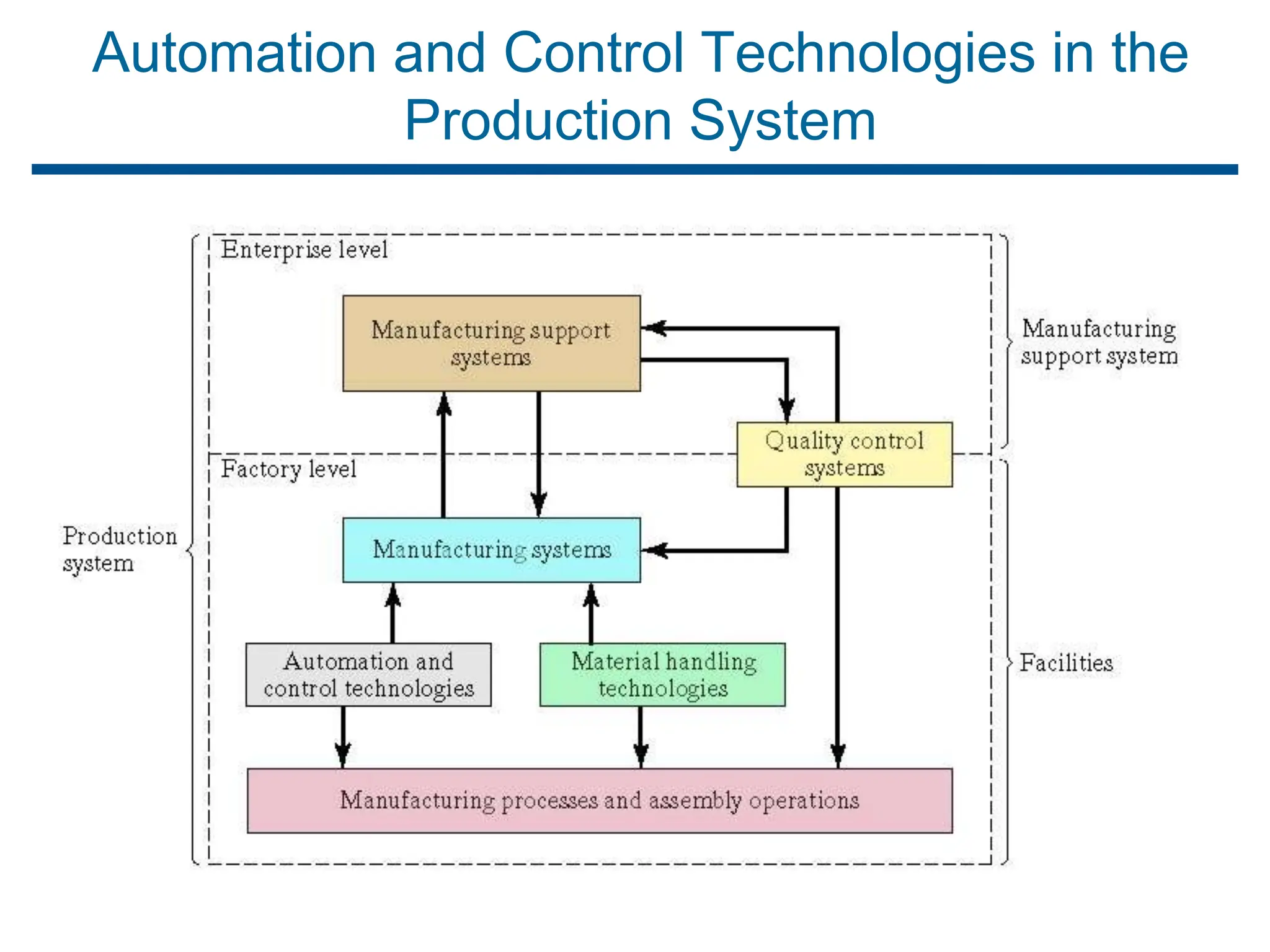

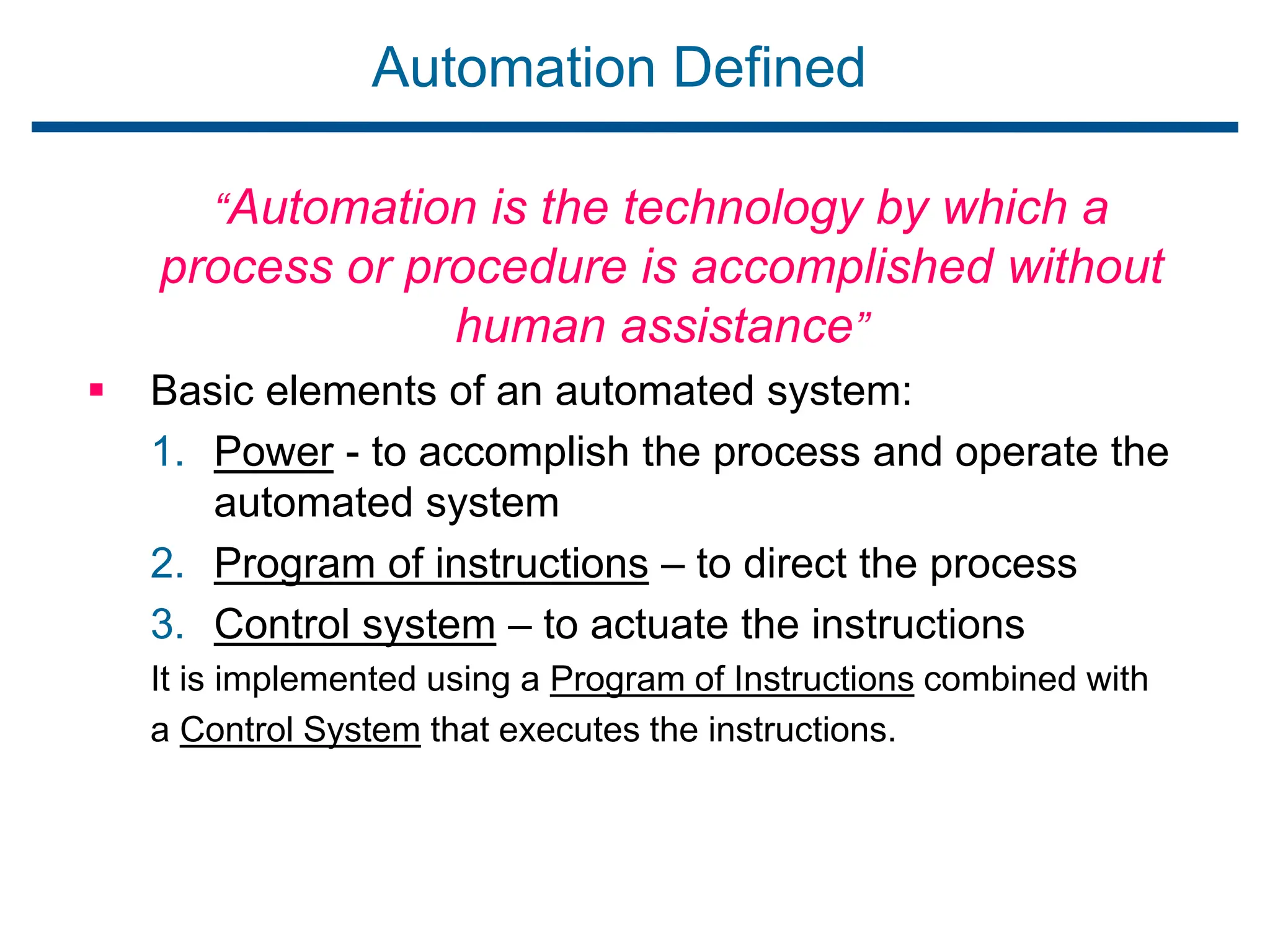

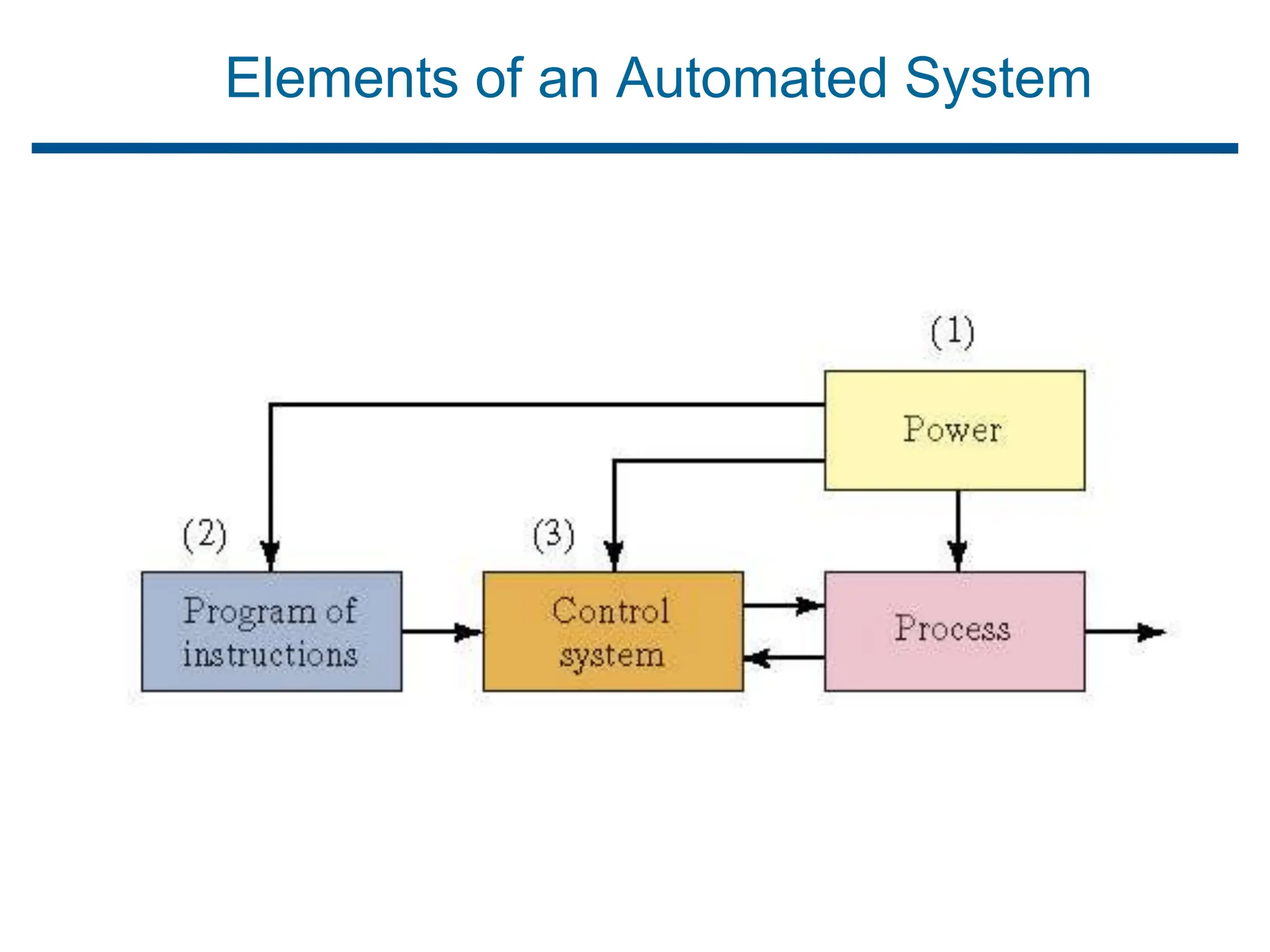

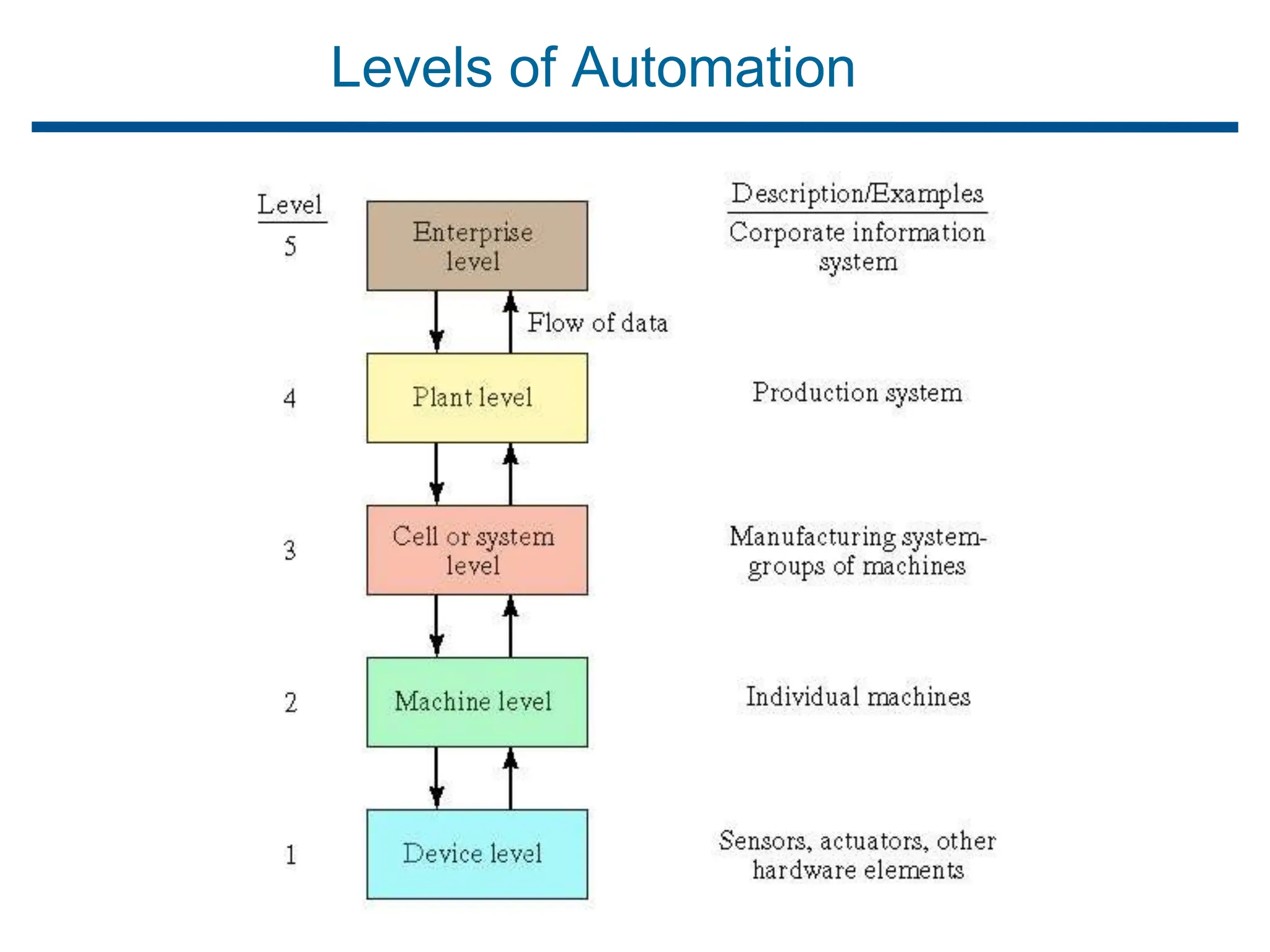

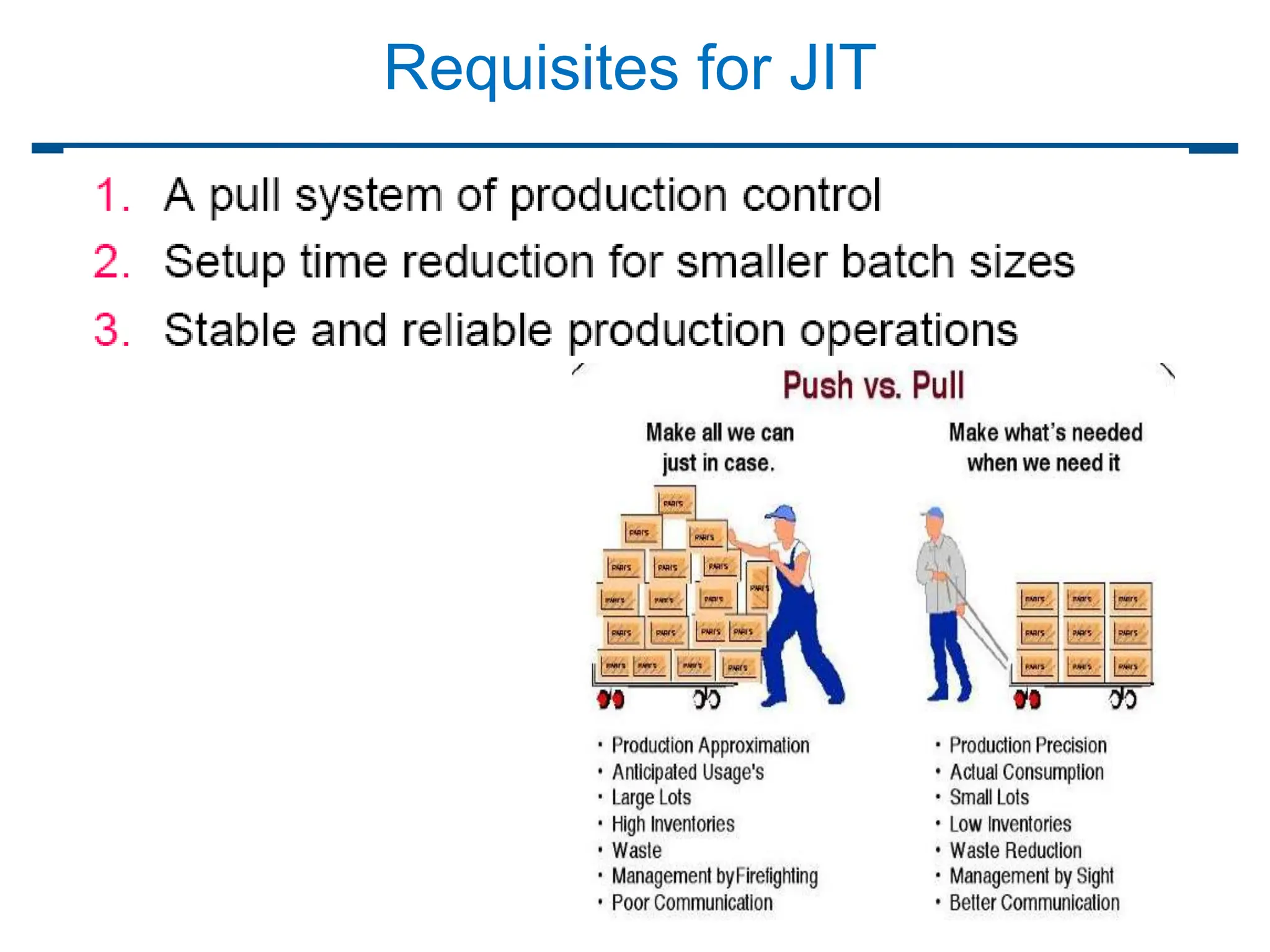

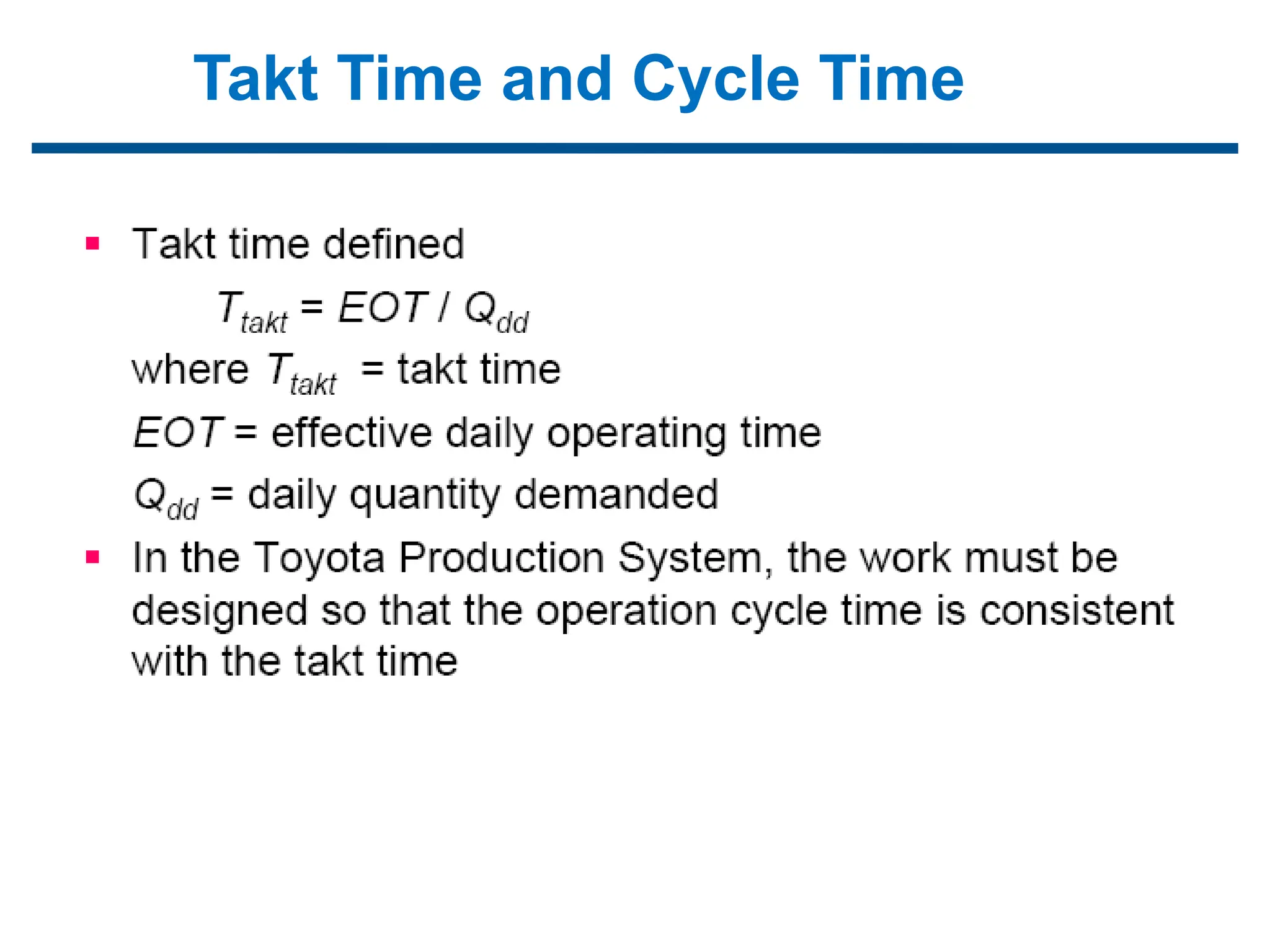

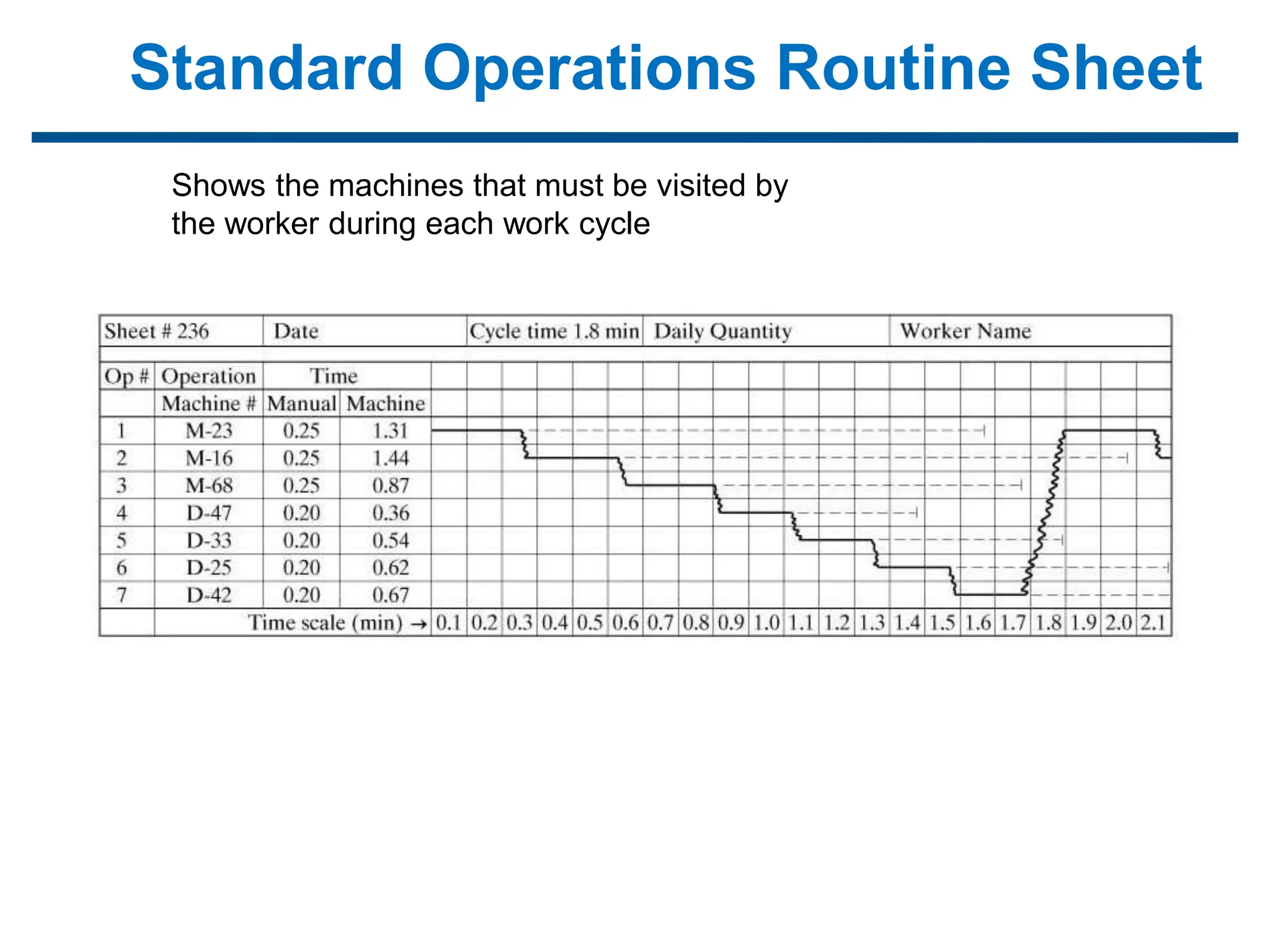

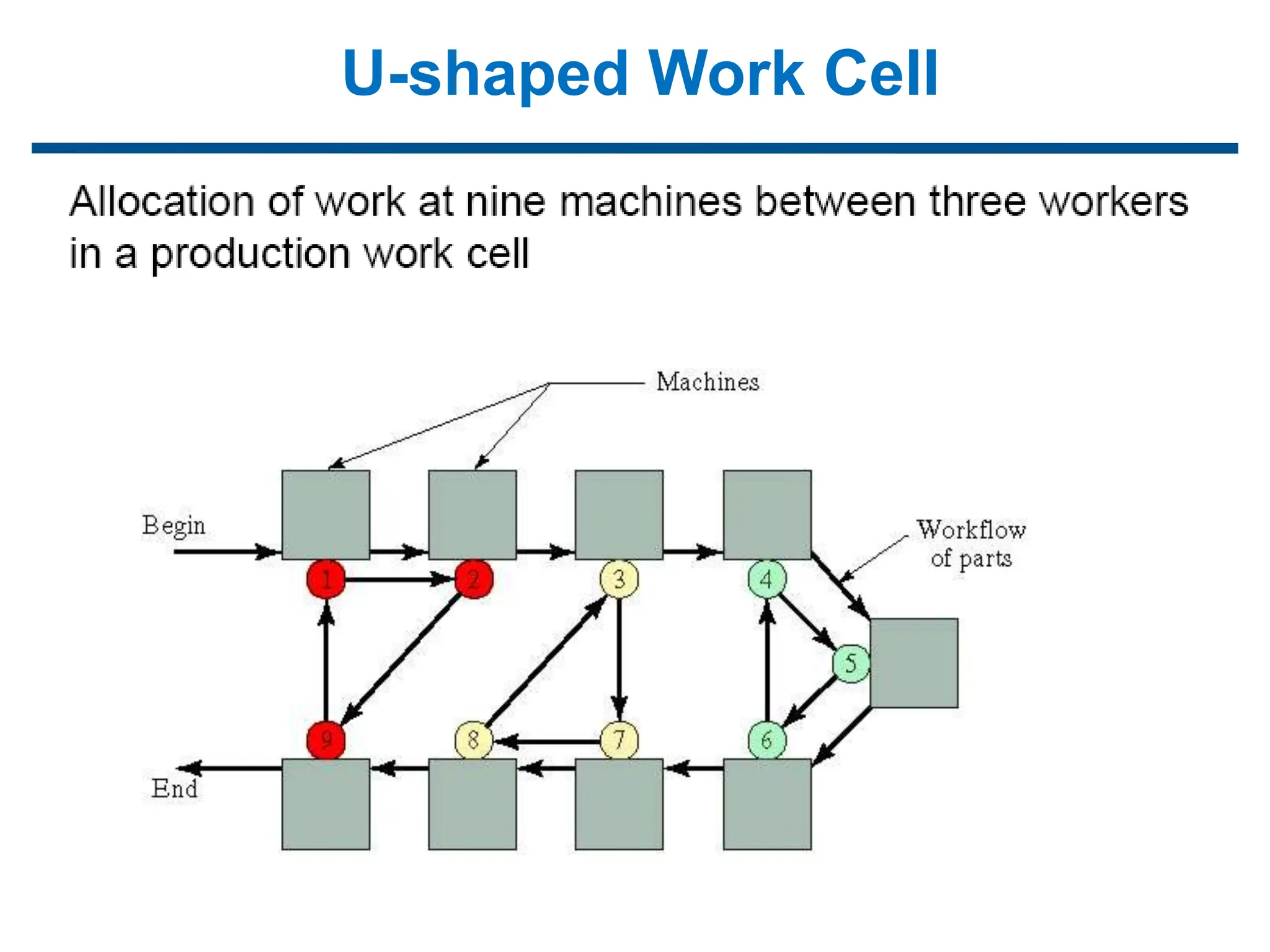

The document provides an overview of computer-aided design (CAD) and computer-aided manufacturing (CAM). It discusses the reasons for implementing CAD, including increasing productivity and improving quality. It describes the basic CAD modeling techniques of wireframe, solid modeling, and engineering analysis tools. The document also outlines common CAM applications in manufacturing planning, such as computer-aided process planning and computer-assisted NC part programming. Applications in manufacturing control discussed include process monitoring, quality control, and just-in-time production systems.