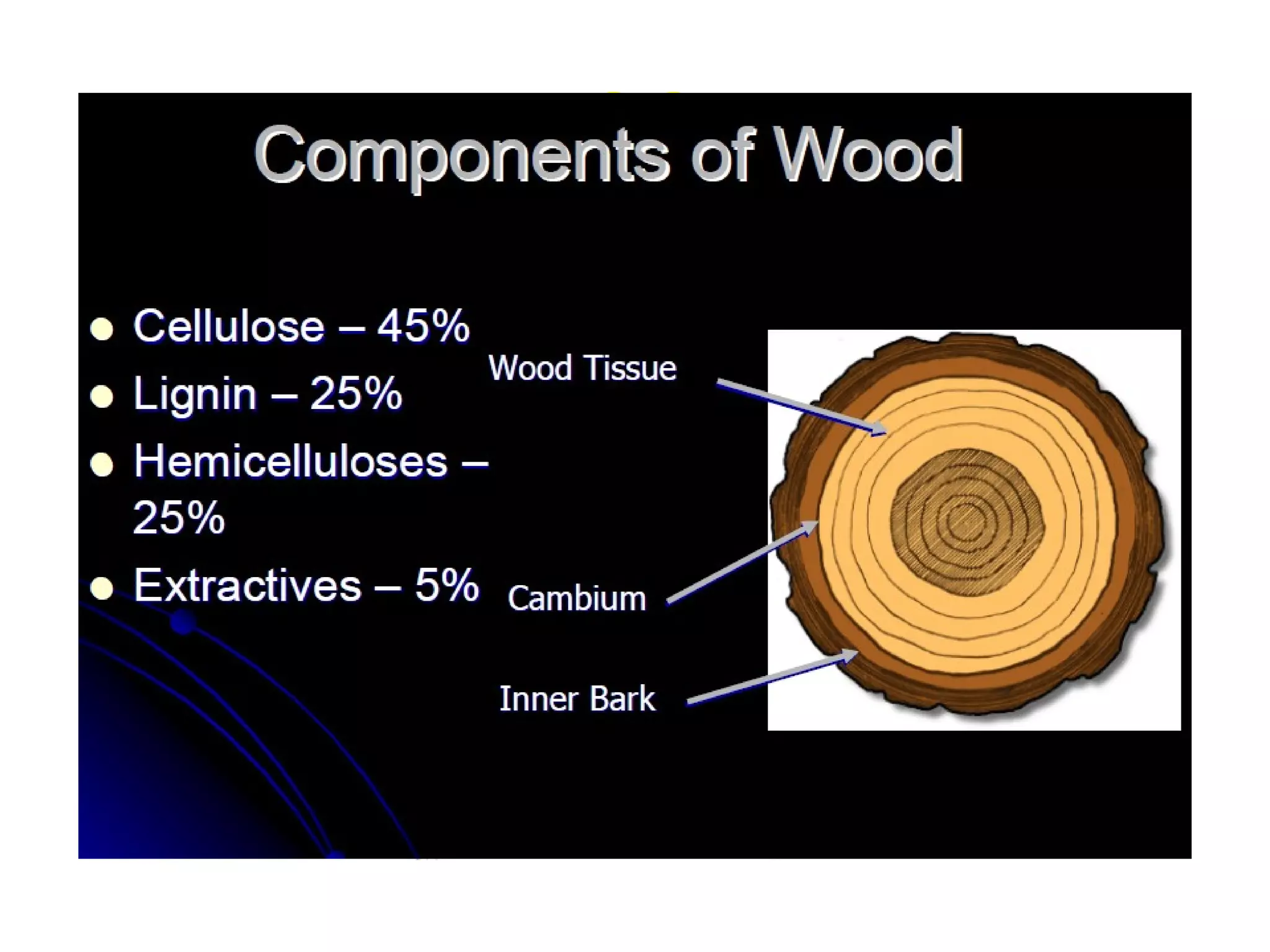

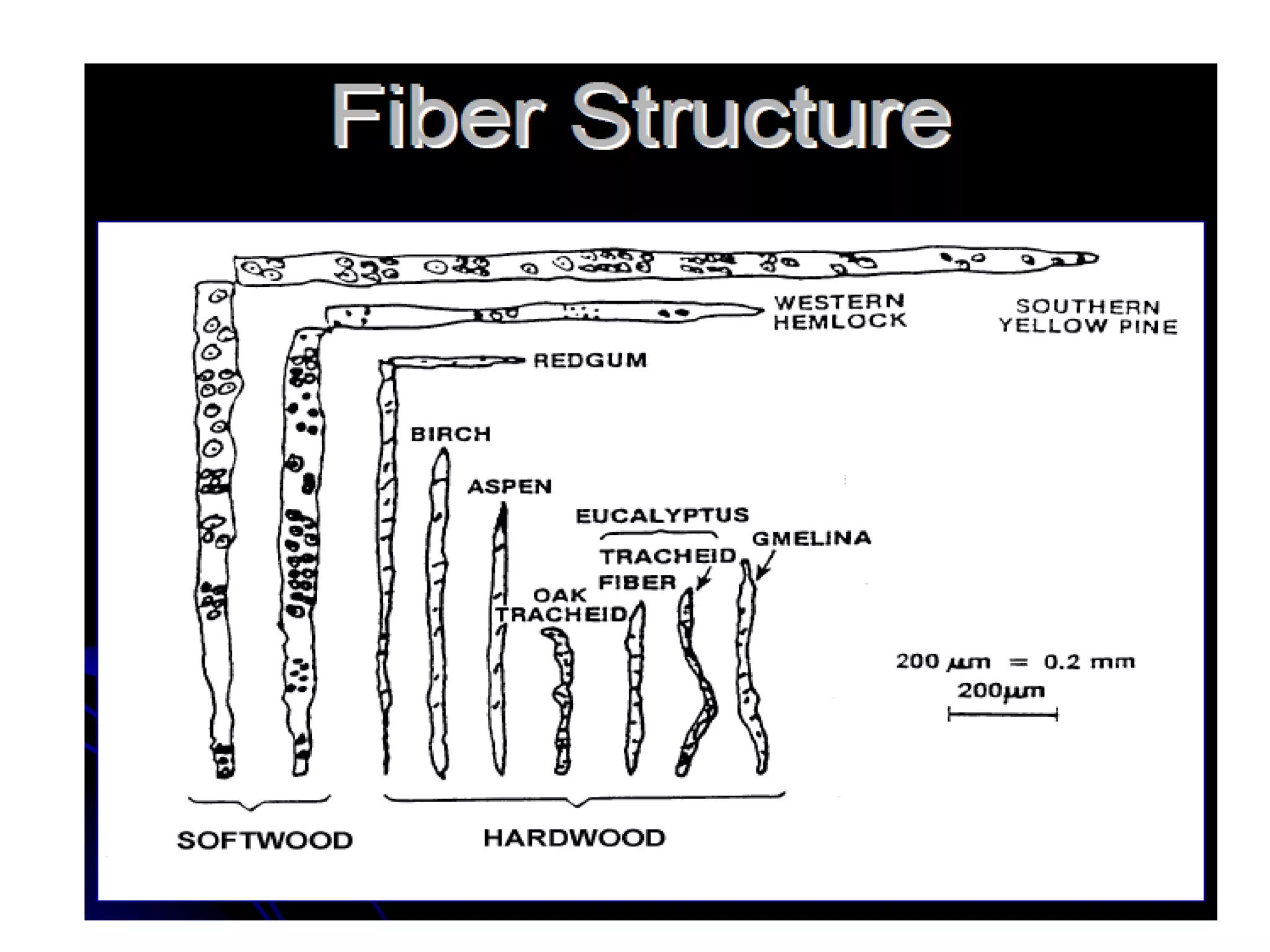

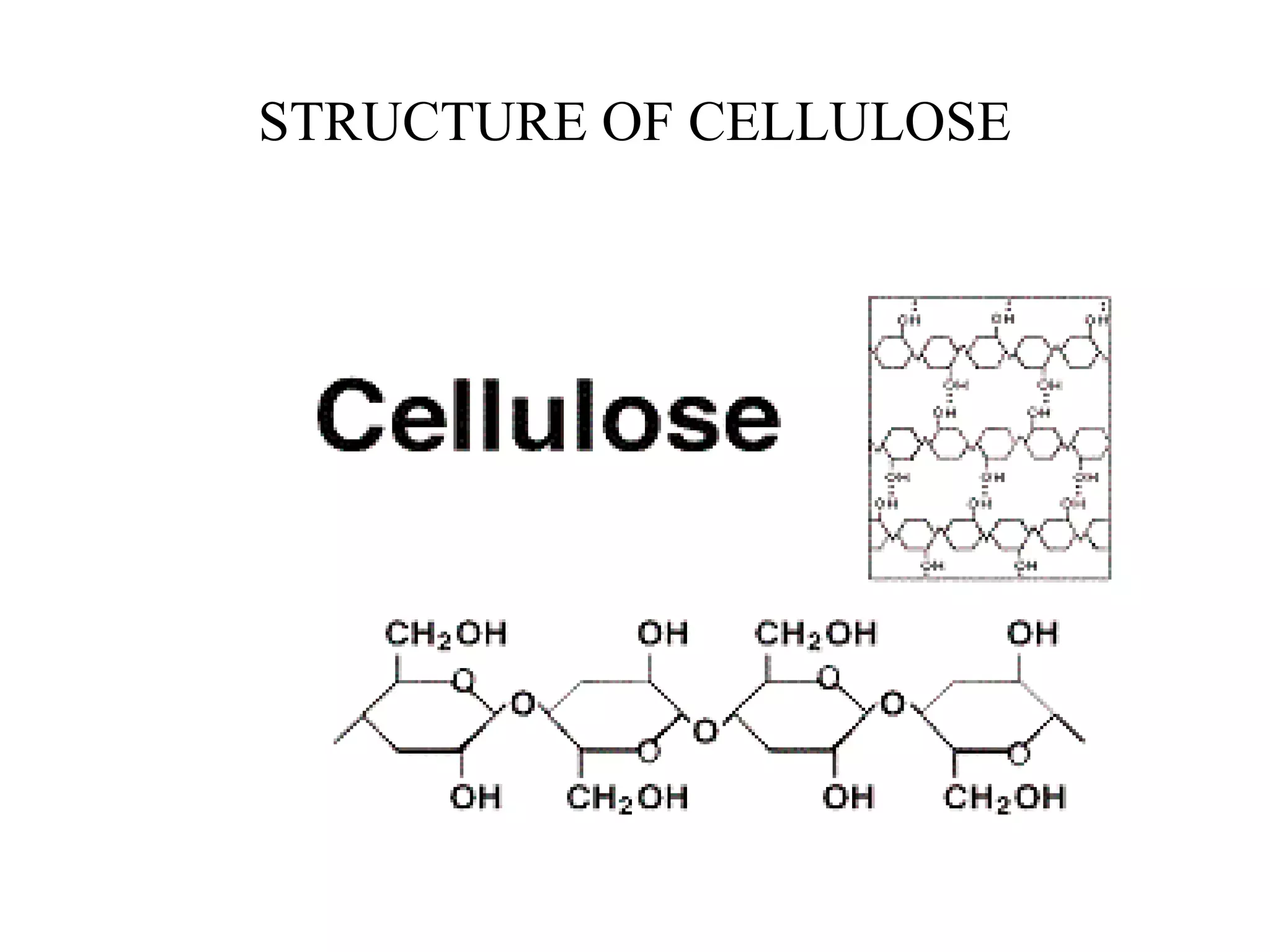

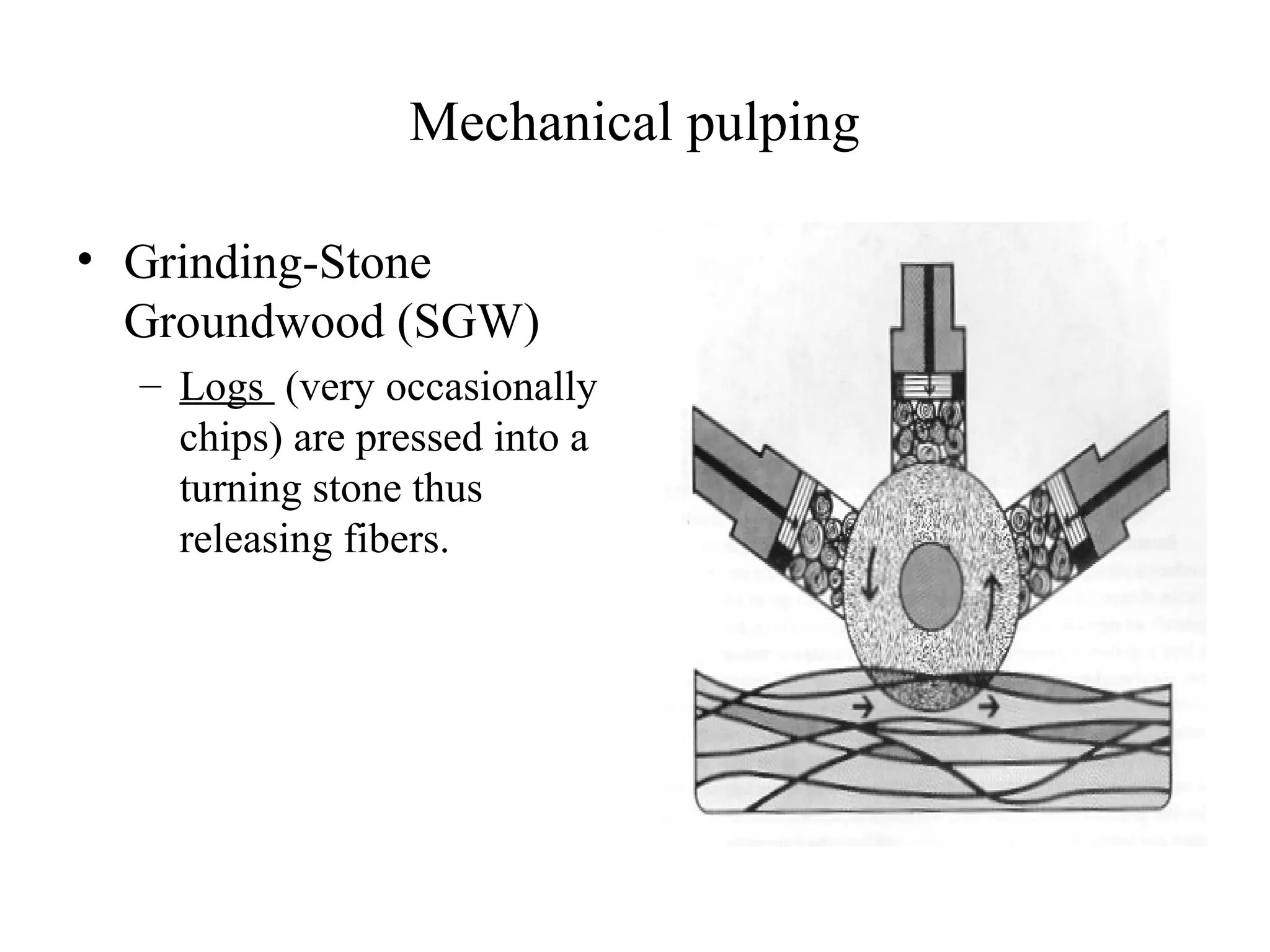

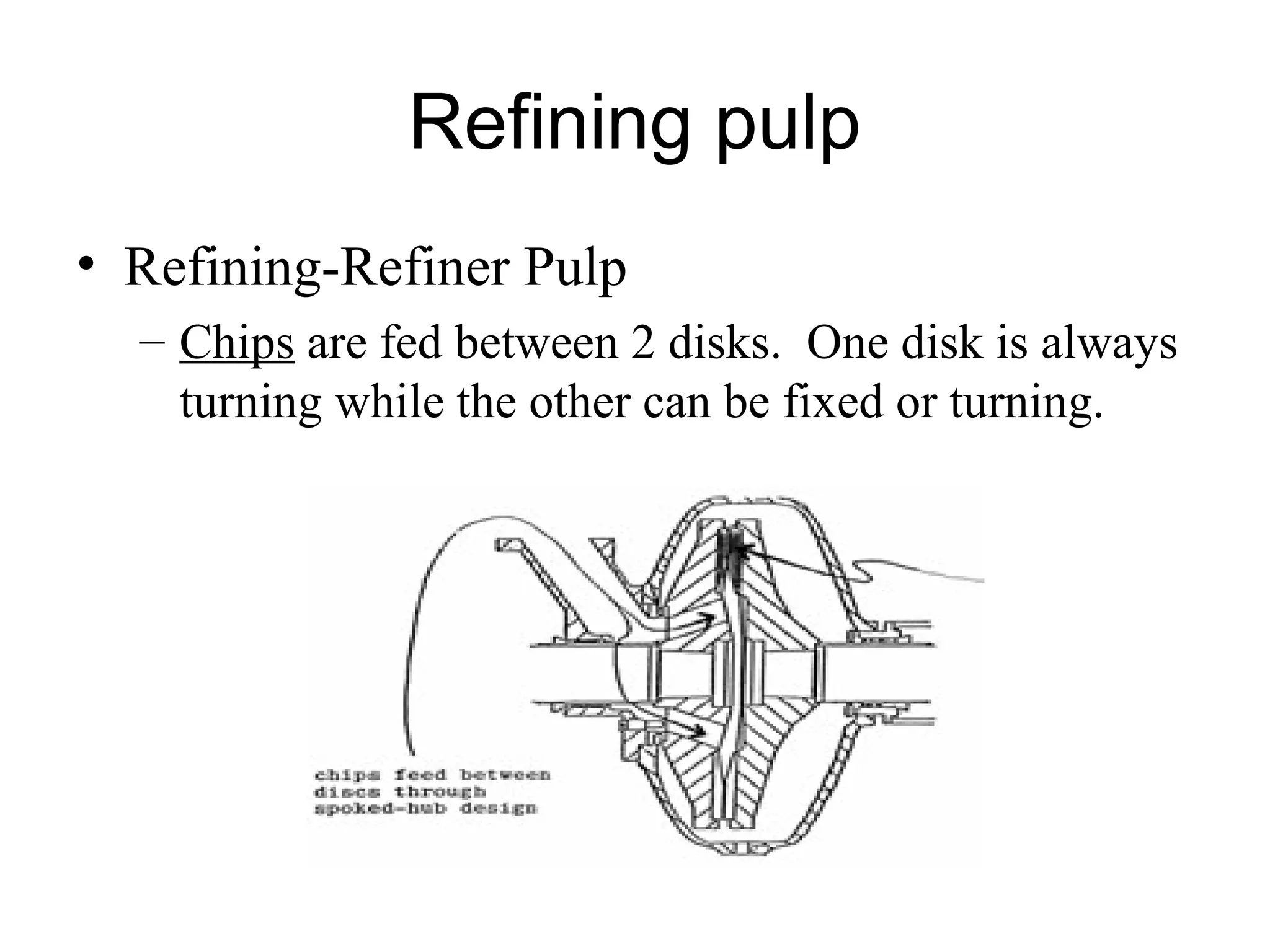

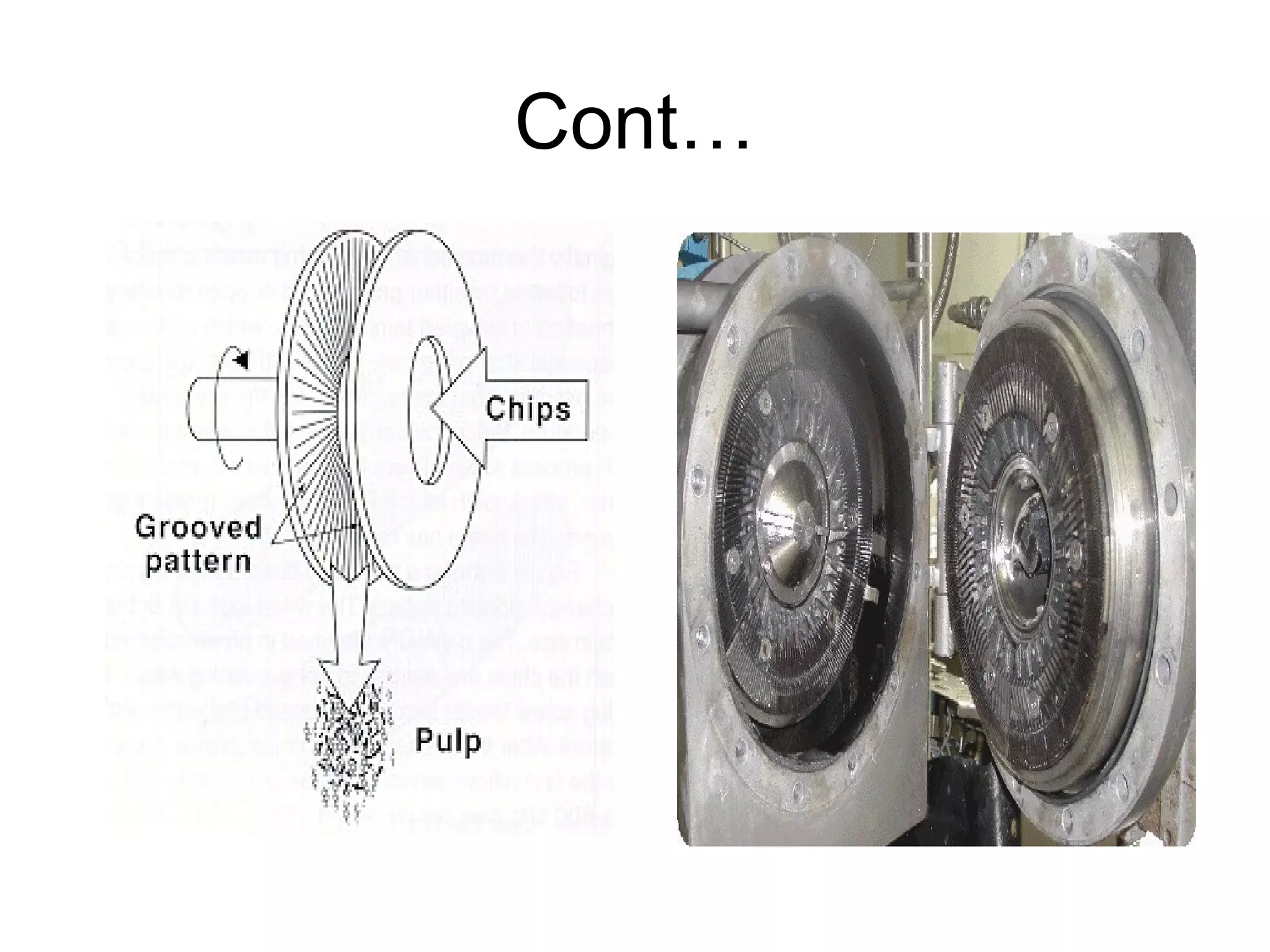

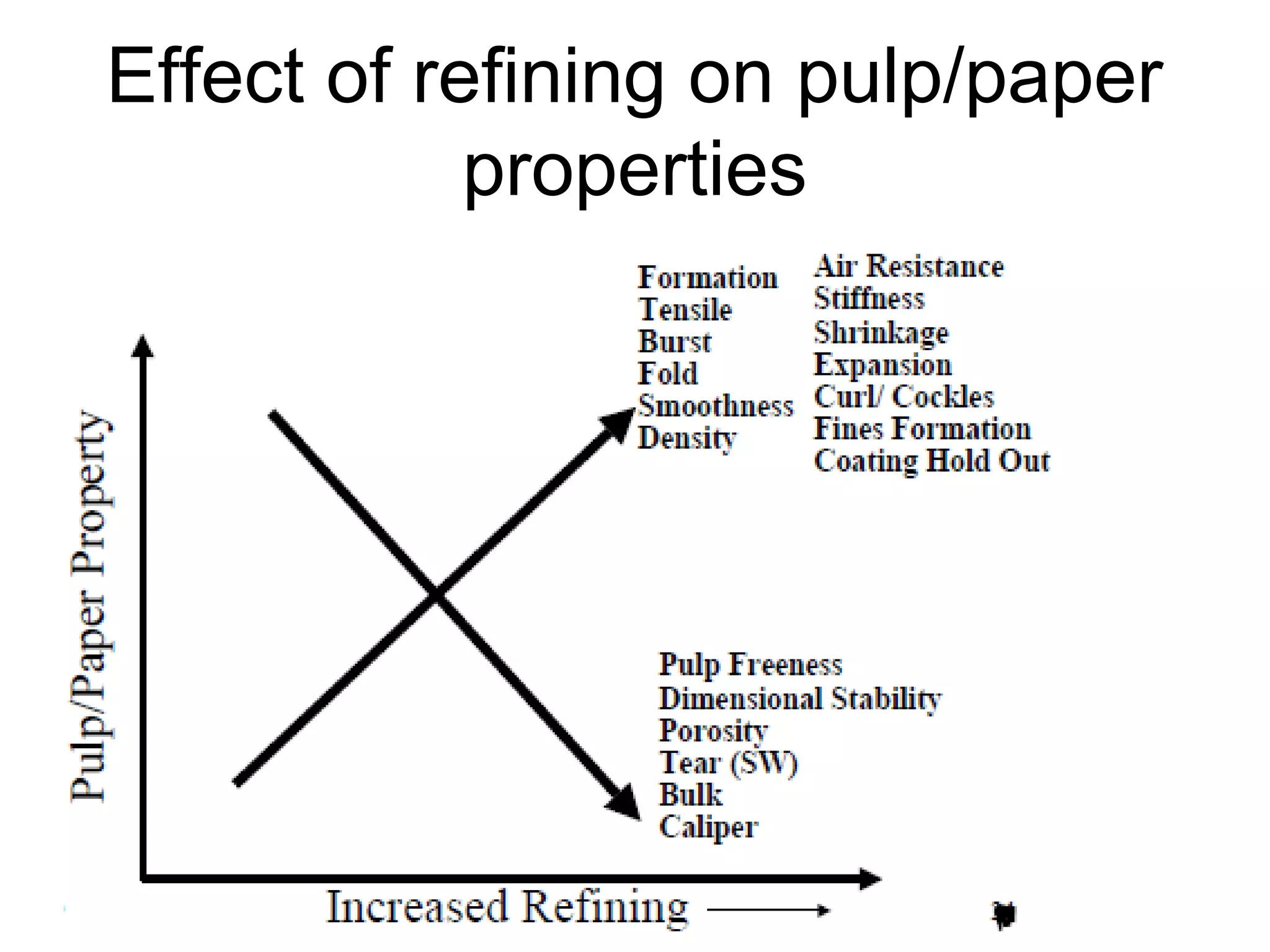

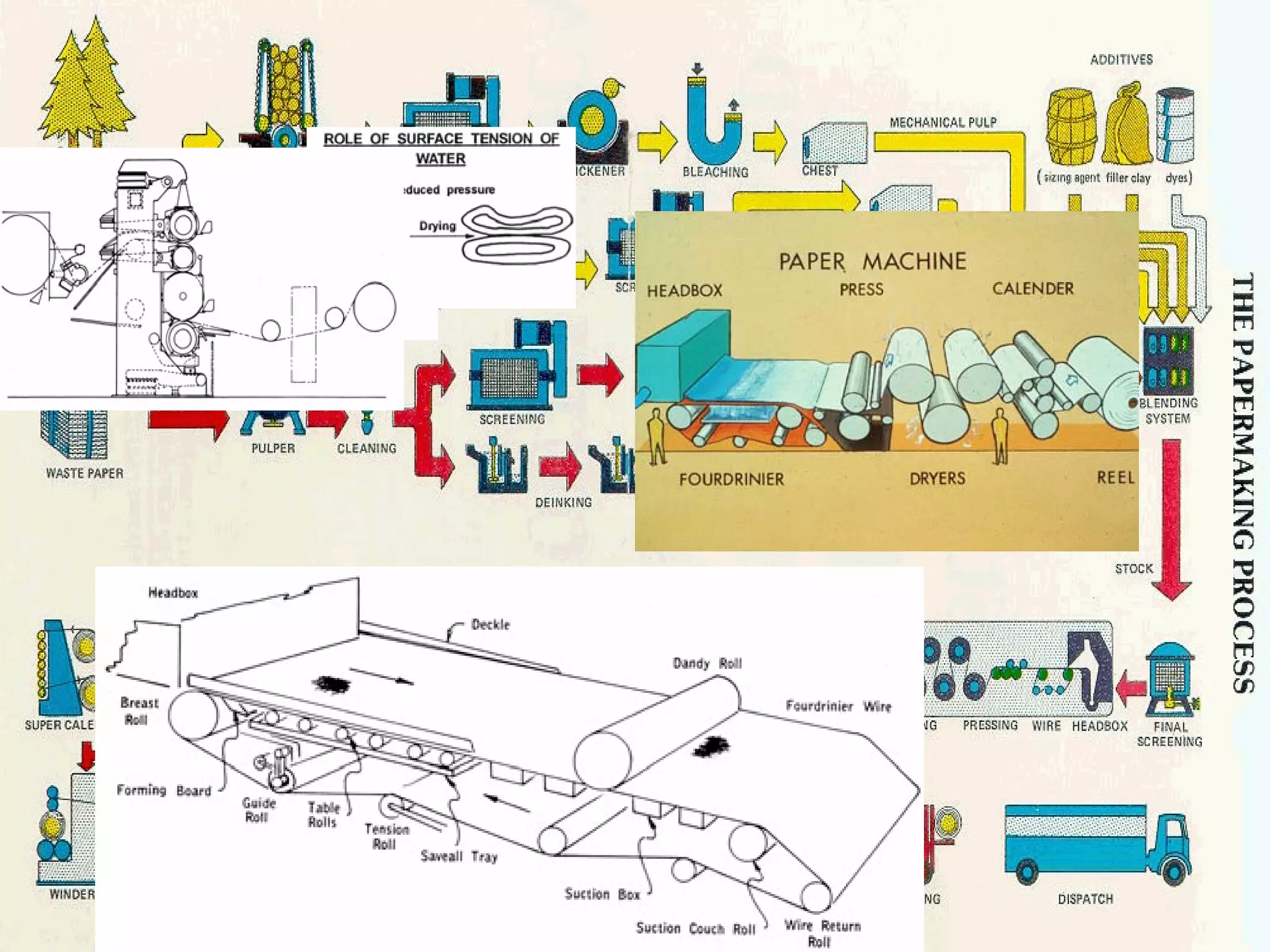

This document provides an overview of the papermaking process. It discusses the various raw materials used, including various plant fibers. It then covers the pulping process, which separates fibers from wood or plant materials. It describes different pulping methods like mechanical, chemical, and combinations. Next, it discusses bleaching, stock preparation, and the addition of fillers and sizing agents. The document concludes with an overview of dyeing methods for paper.