The document summarizes the pulp and paper industry processes. Key points include:

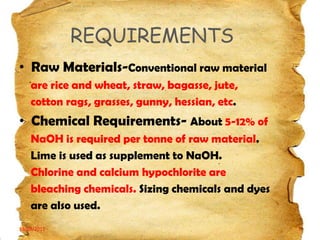

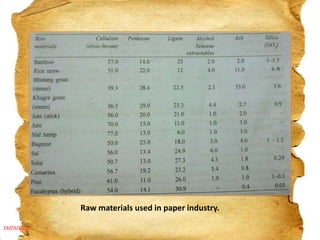

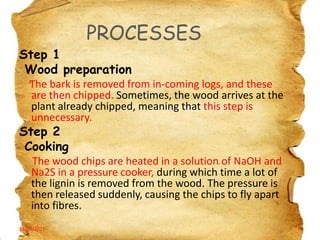

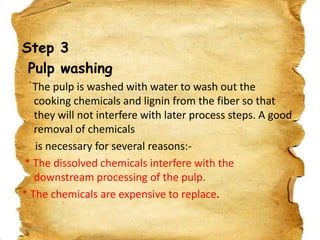

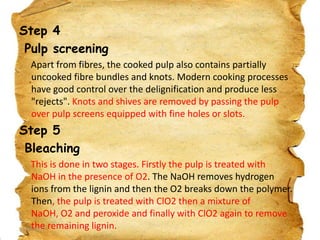

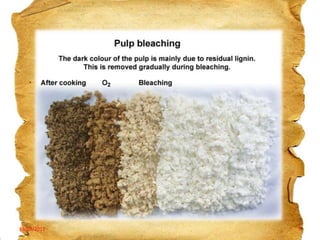

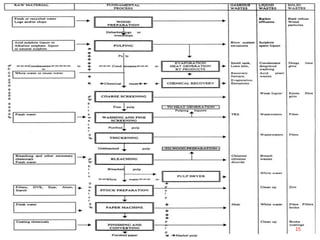

- Raw materials like wood, rice straw and cotton are used and undergo cooking, washing, screening and bleaching.

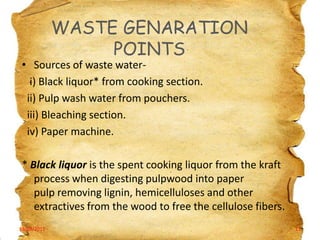

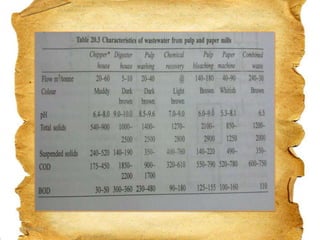

- Wastewater is generated from the cooking, washing, bleaching and papermaking steps.

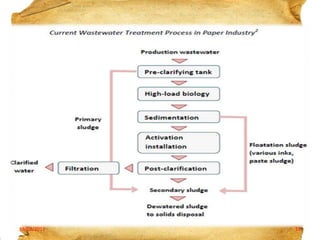

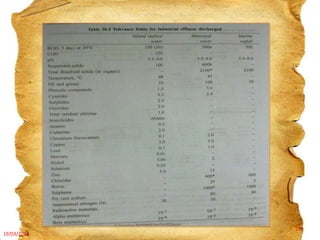

- Treatment schemes include sedimentation and flocculation to remove impurities from wastewater before discharge.

- Innovative technologies like using enzymes and polymers can improve wastewater treatment and paper quality.