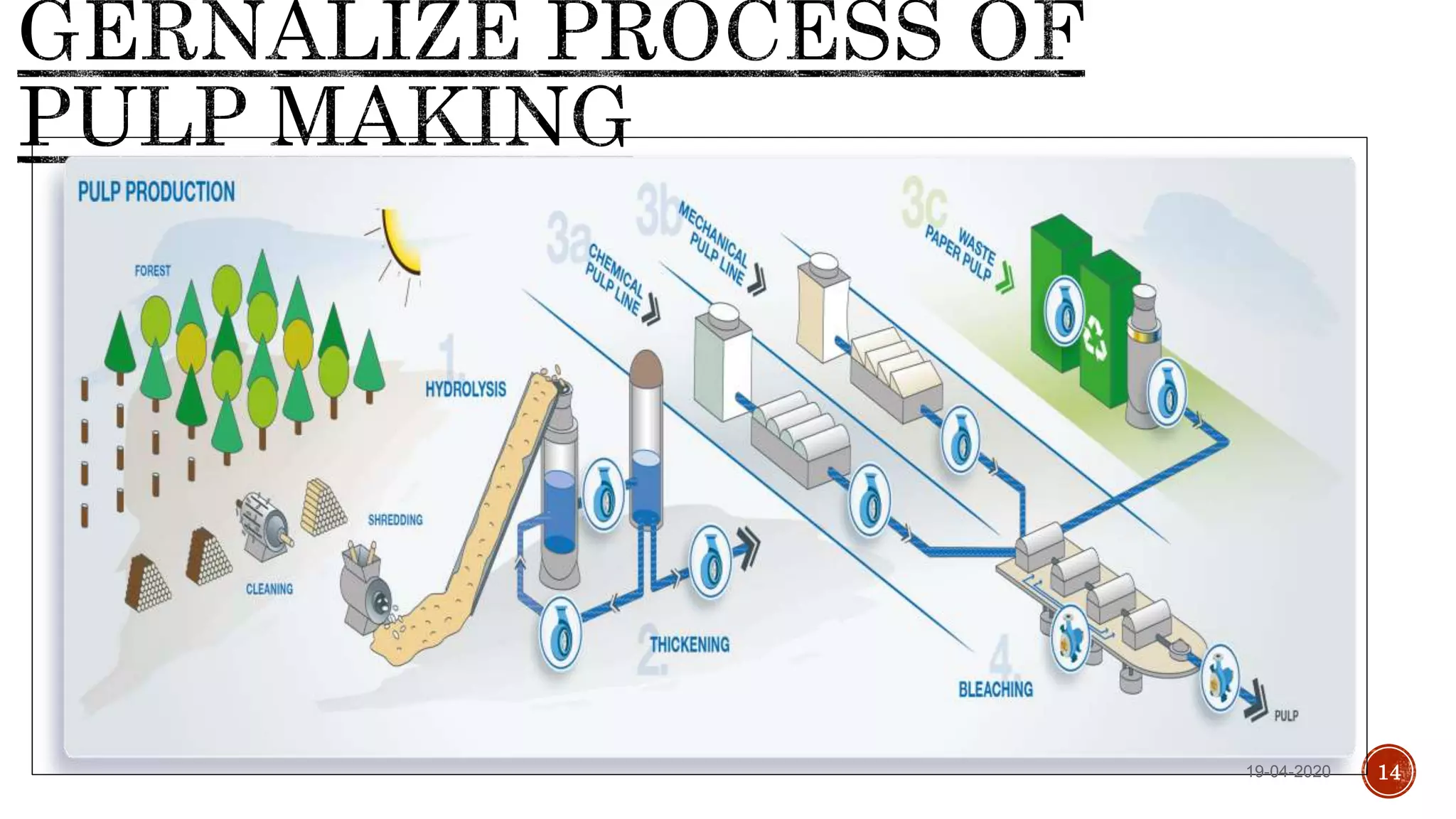

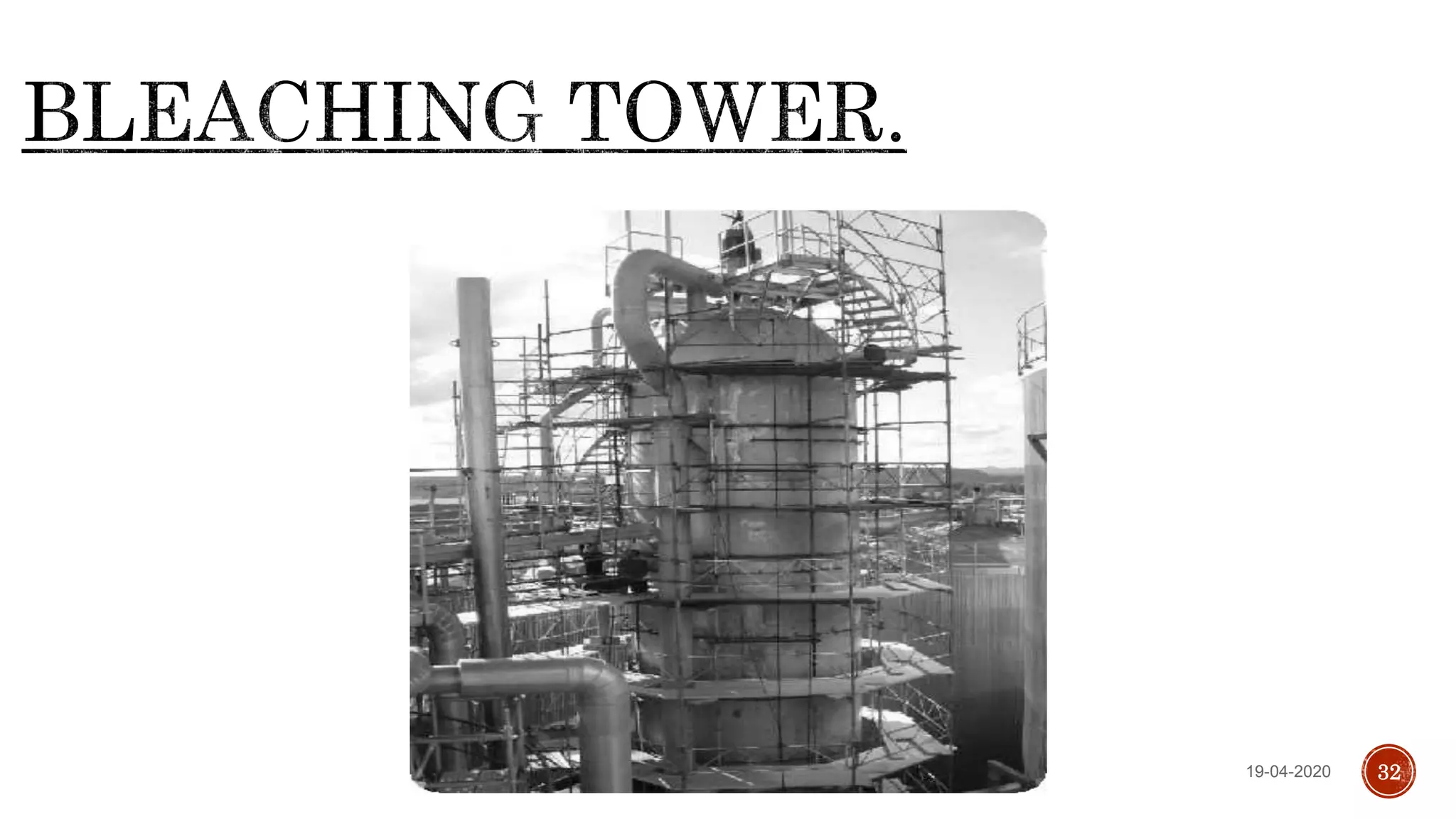

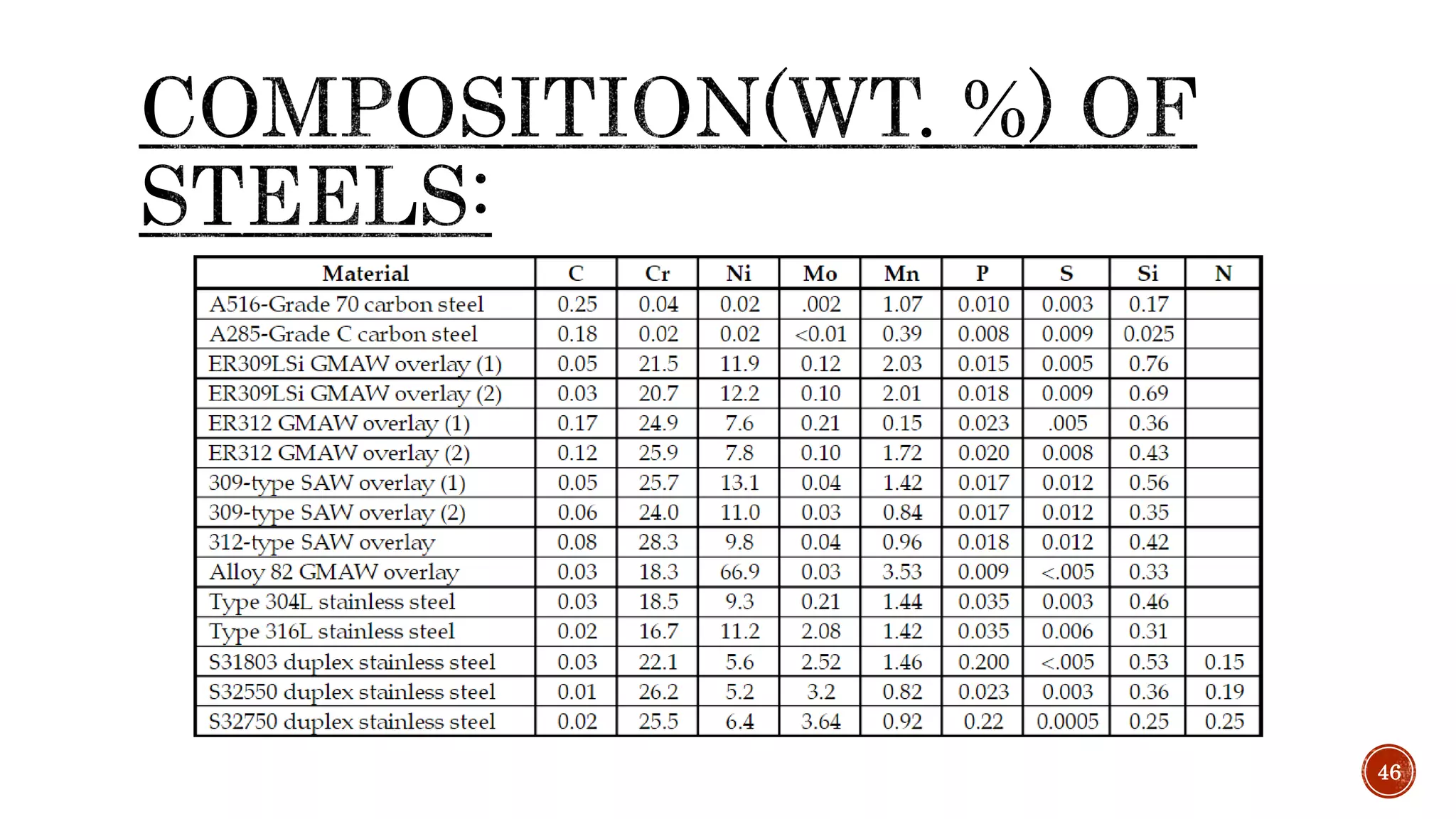

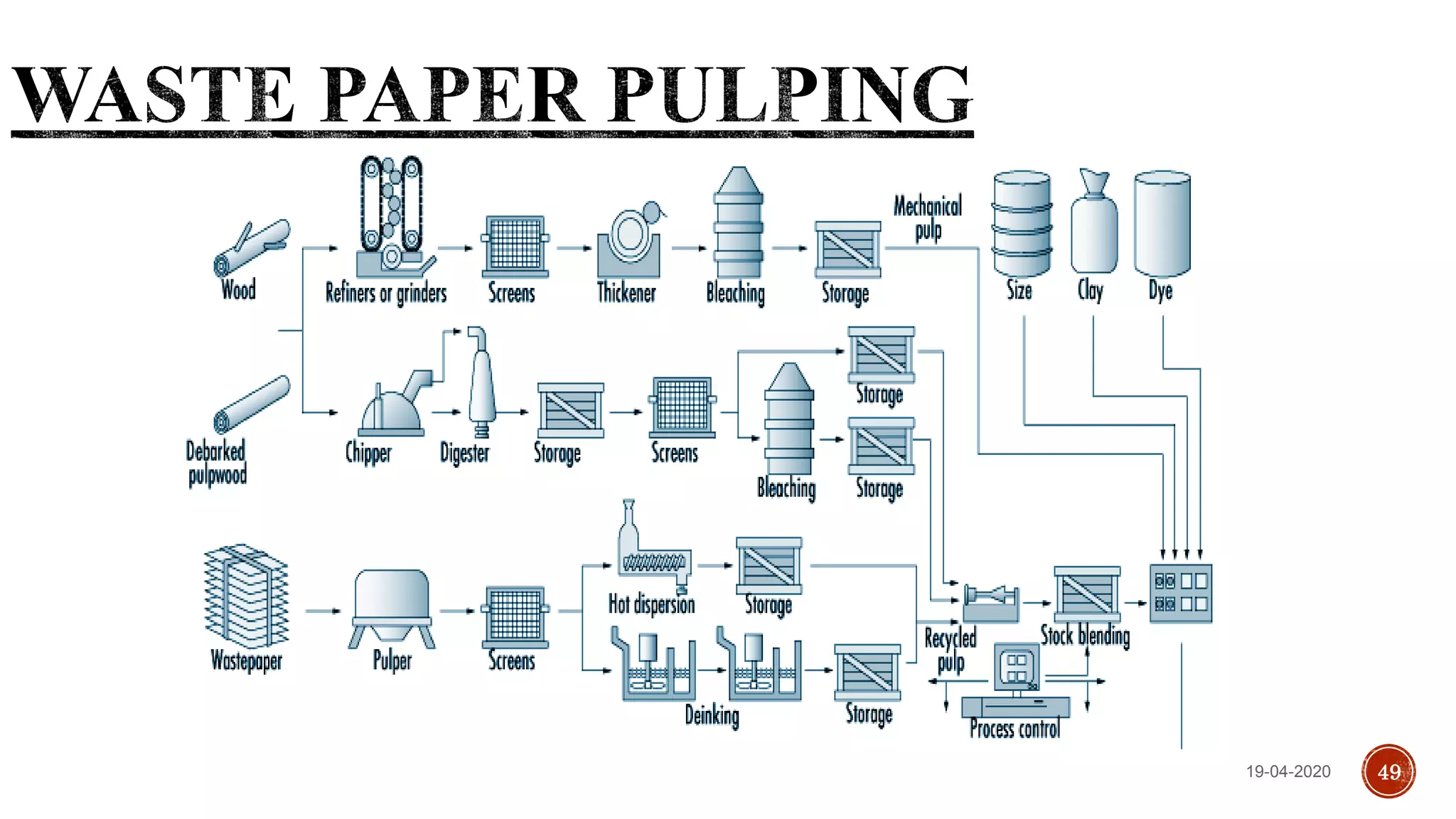

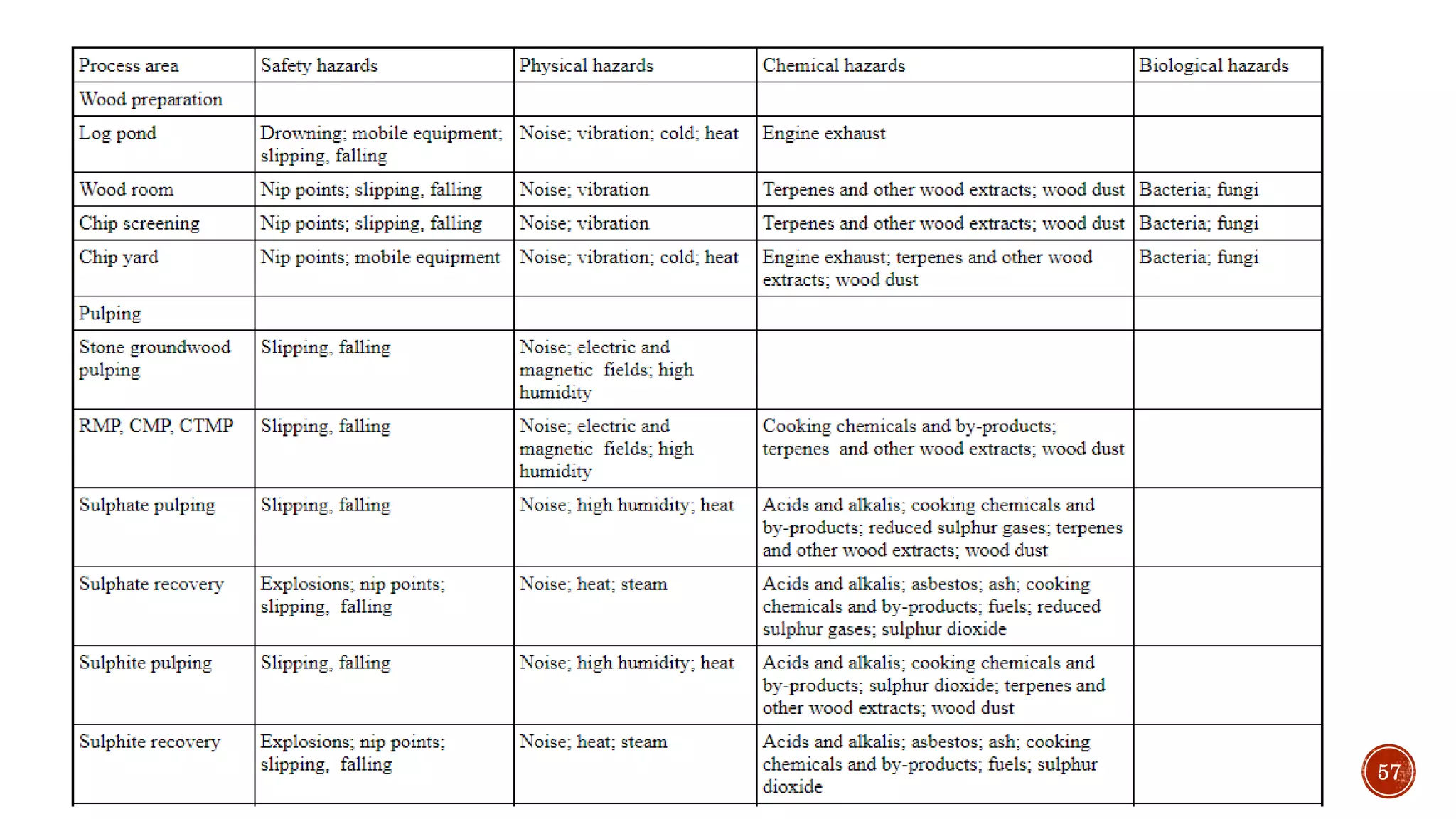

The document discusses the process of pulp making from various raw materials like wood, bagasse, and recycled paper. It describes the key steps in pulp making which include debarking, chipping, impregnation, cooking, screening, washing, bleaching, and recovery processes. It also discusses the different pulping methods like mechanical, chemical and semi-chemical pulping and highlights the Kraft and sulfite processes. The document further provides details on equipment used, materials of construction, advances in pulping technology and various bleaching agents.

![ [1] N. DeKing, Ed., Pulp & Paper Global Fact & Price Book 2003–2004. Boston:

Paperloop, Inc., 2004.

[2] G.A. Smook, Handbook for Pulp and Paper Technologists, 2nd ed. Vancouver,

BC, Canada: Angus Wilde, 1992.

[3] F. Kayihan, “A review of modeling and control in pulp and paper industries,”

in Proc. 5th Int. Conf. Chemical Process Control (CPC V): AIChE Symp.

Ser., 1997, pp. 117–132.

[4] J. Minor, “Pulp,” in Kirk-Othmer Encyclopedia of Chemical Technology, 3rd

ed. , M. Grayson, Ed. New York: Wiley, 1982, vol. 19, pp. 379–419.

http://en.wikipedia.org/wiki/Pulp_and_paper_industry.

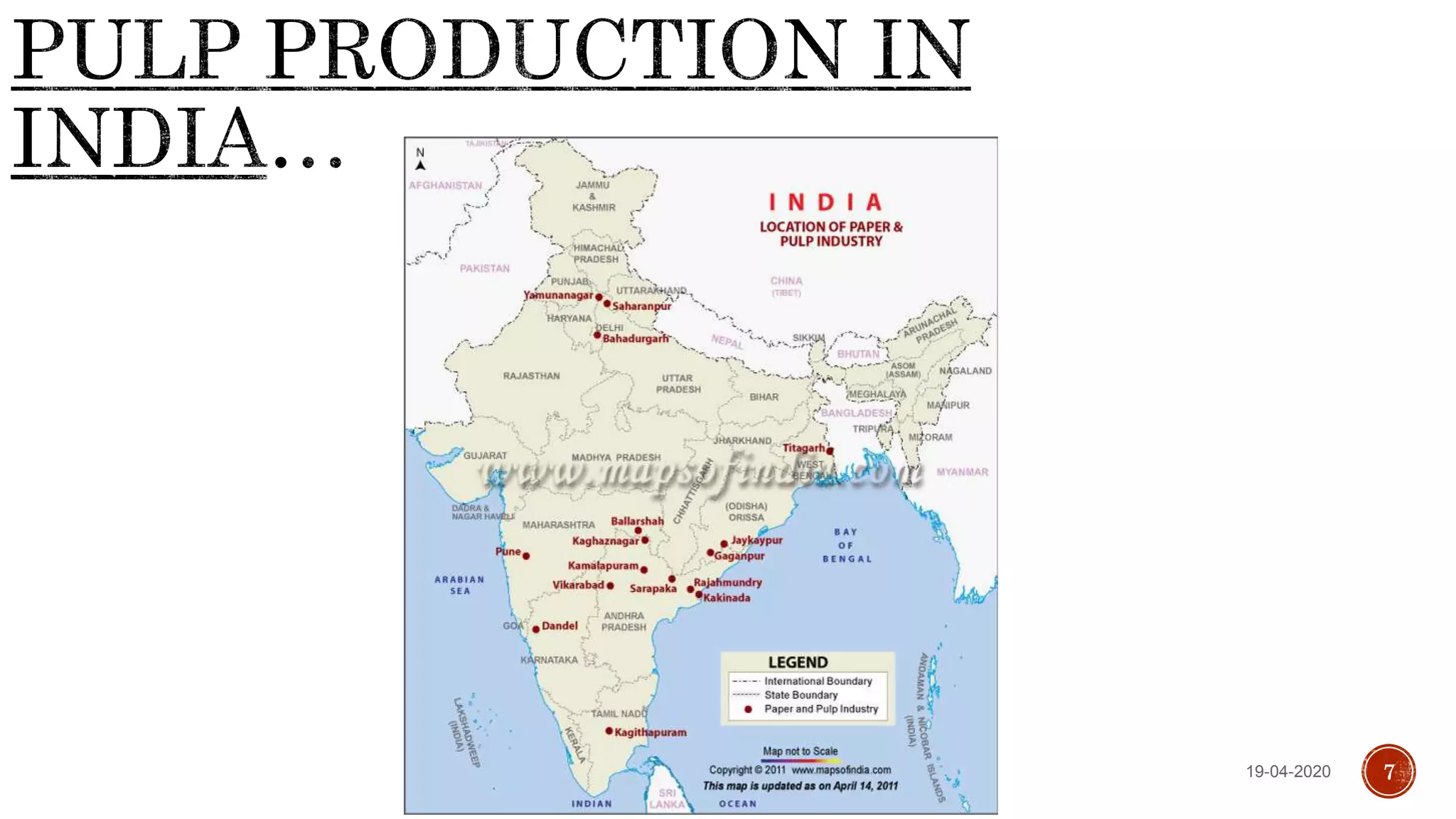

https://business.mapsofindia.com/paper-and-pulp-industry/

https://www.stainless-structurals.com/blog/stainless-steel-pulp-and-paper-industry/

https://www.nickelinstitute.org/about-nickel/pulp-paper/

http://www.ilocis.org/documents/chpt72e.html

6719-04-2020](https://image.slidesharecdn.com/pulpproduction-200419100235/75/Pulp-production-67-2048.jpg)