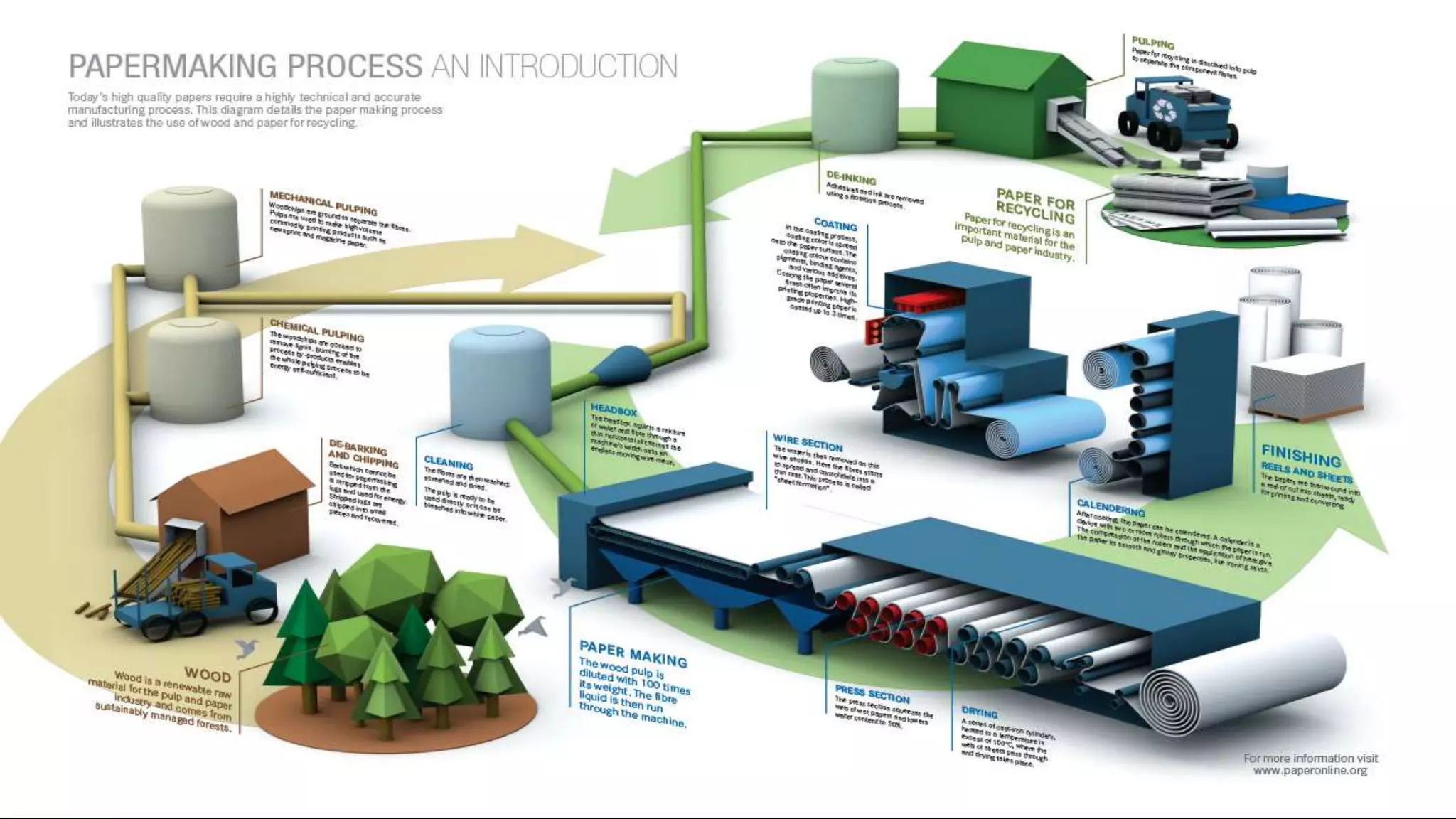

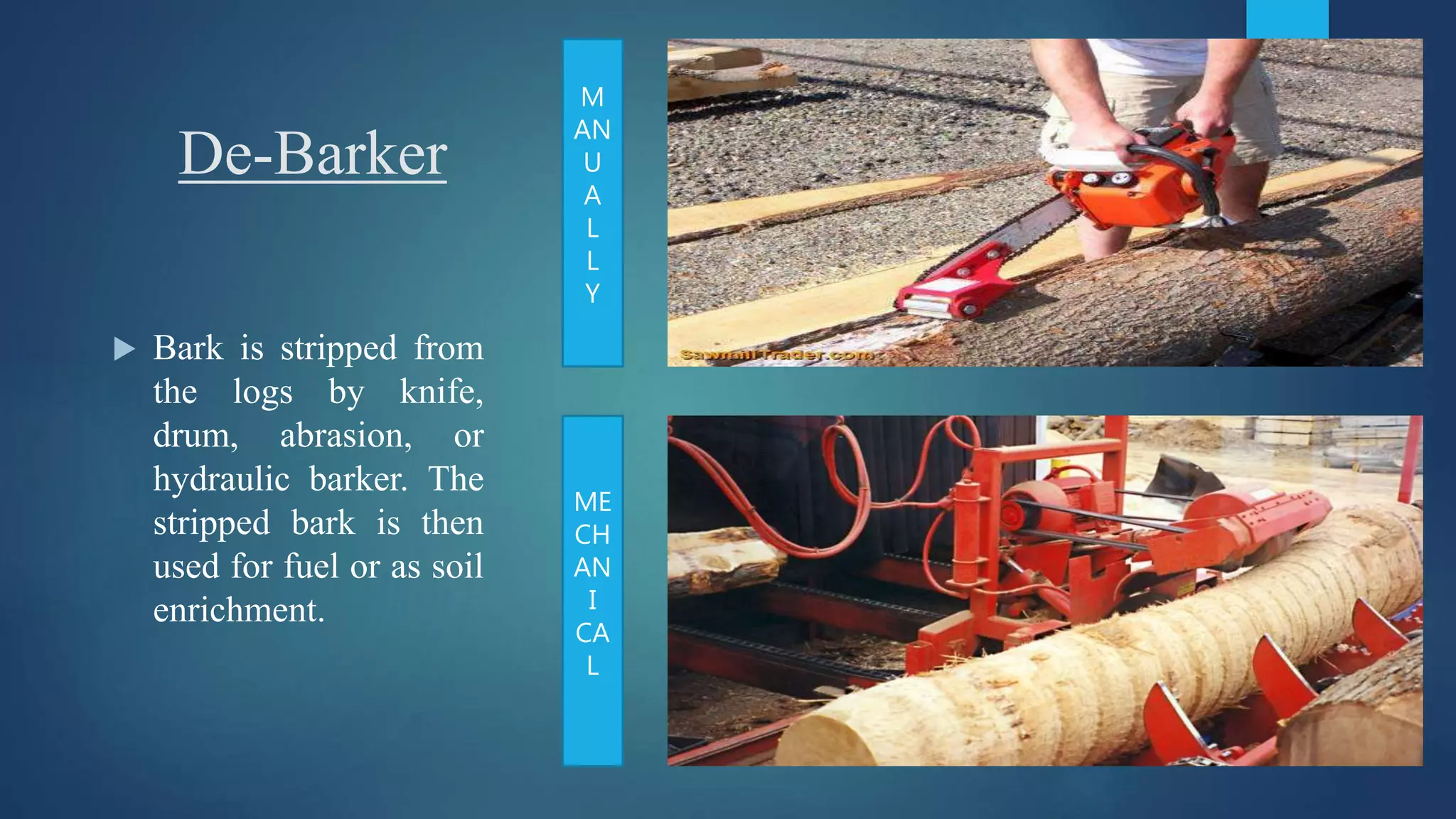

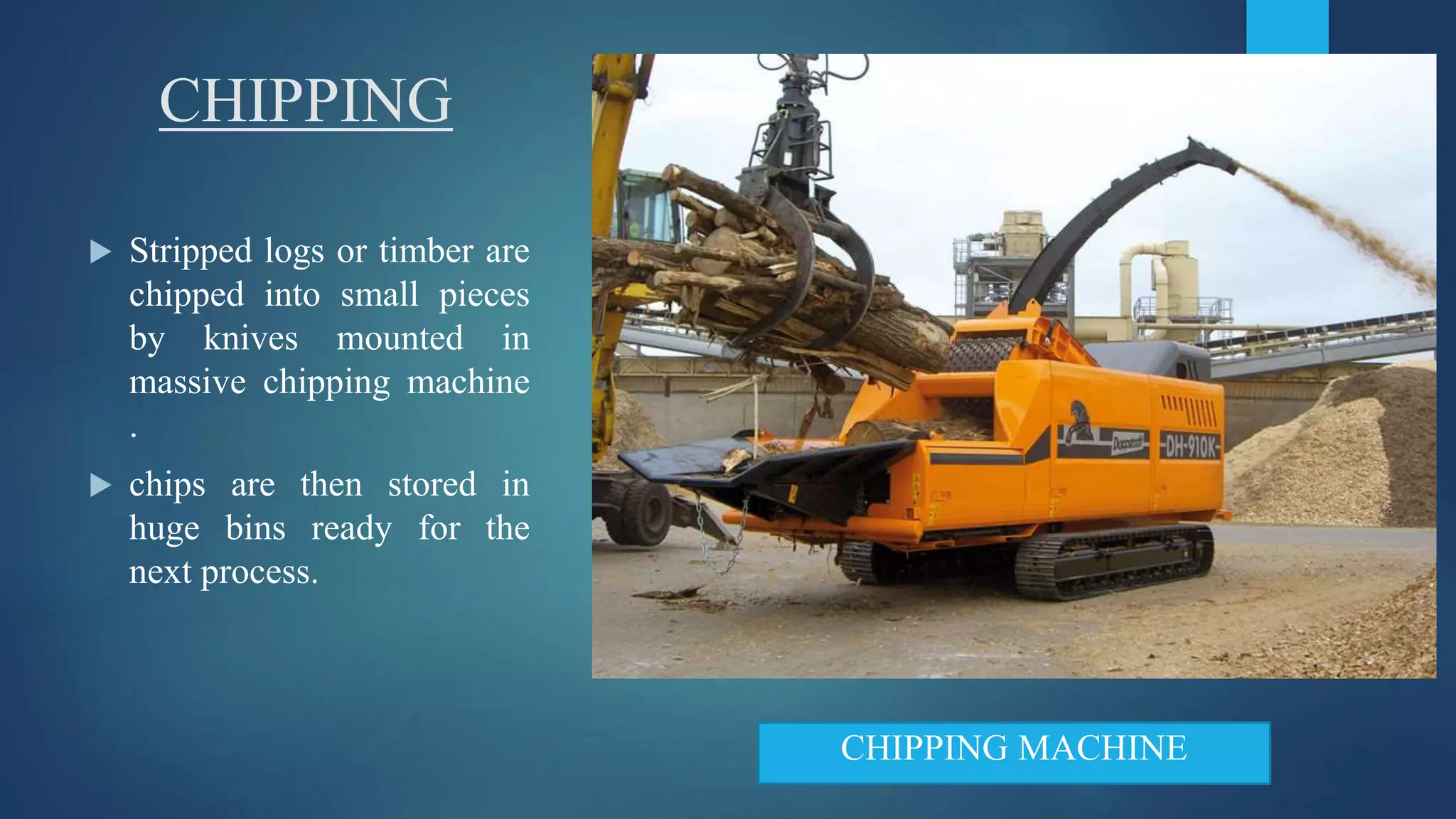

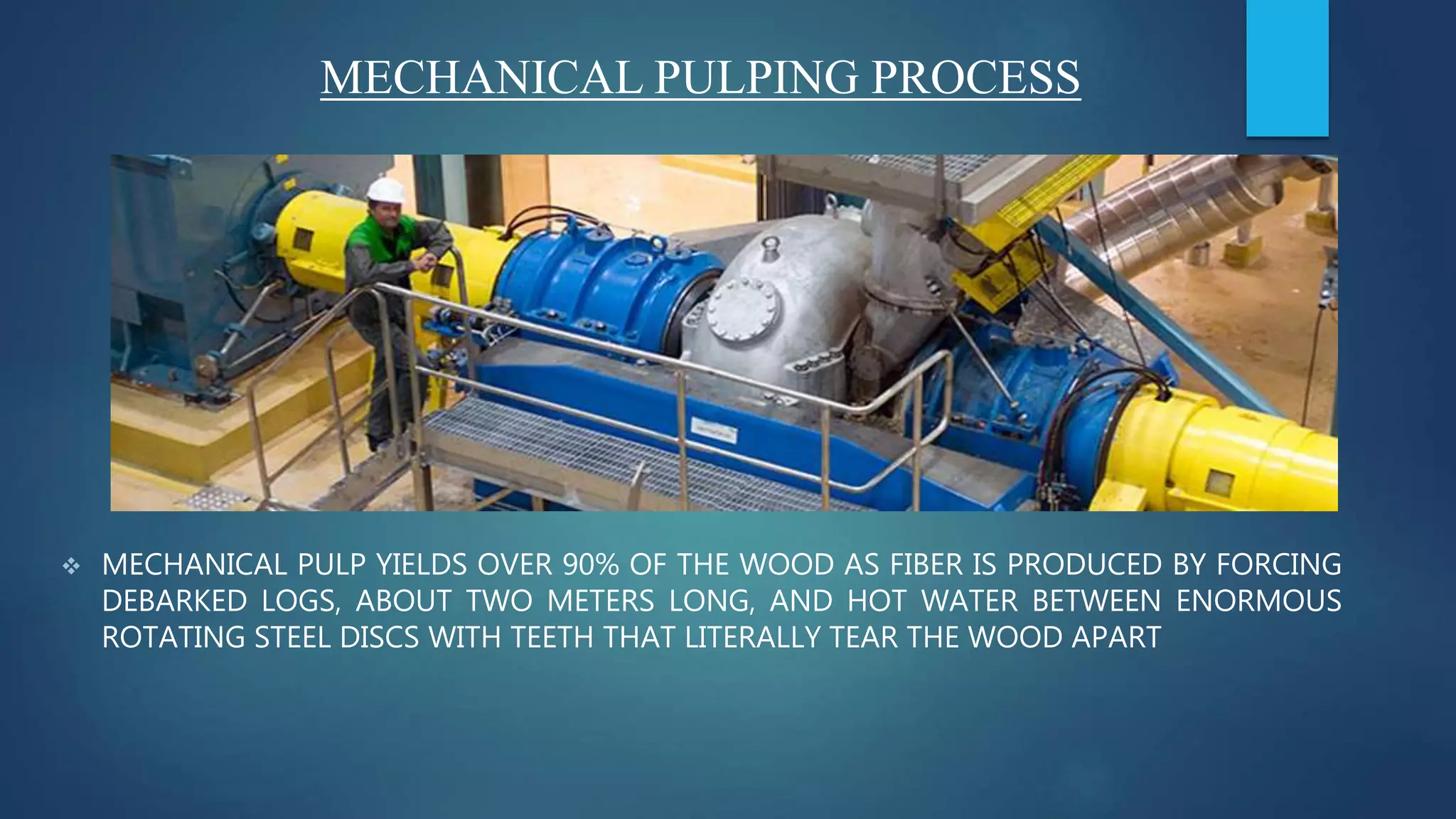

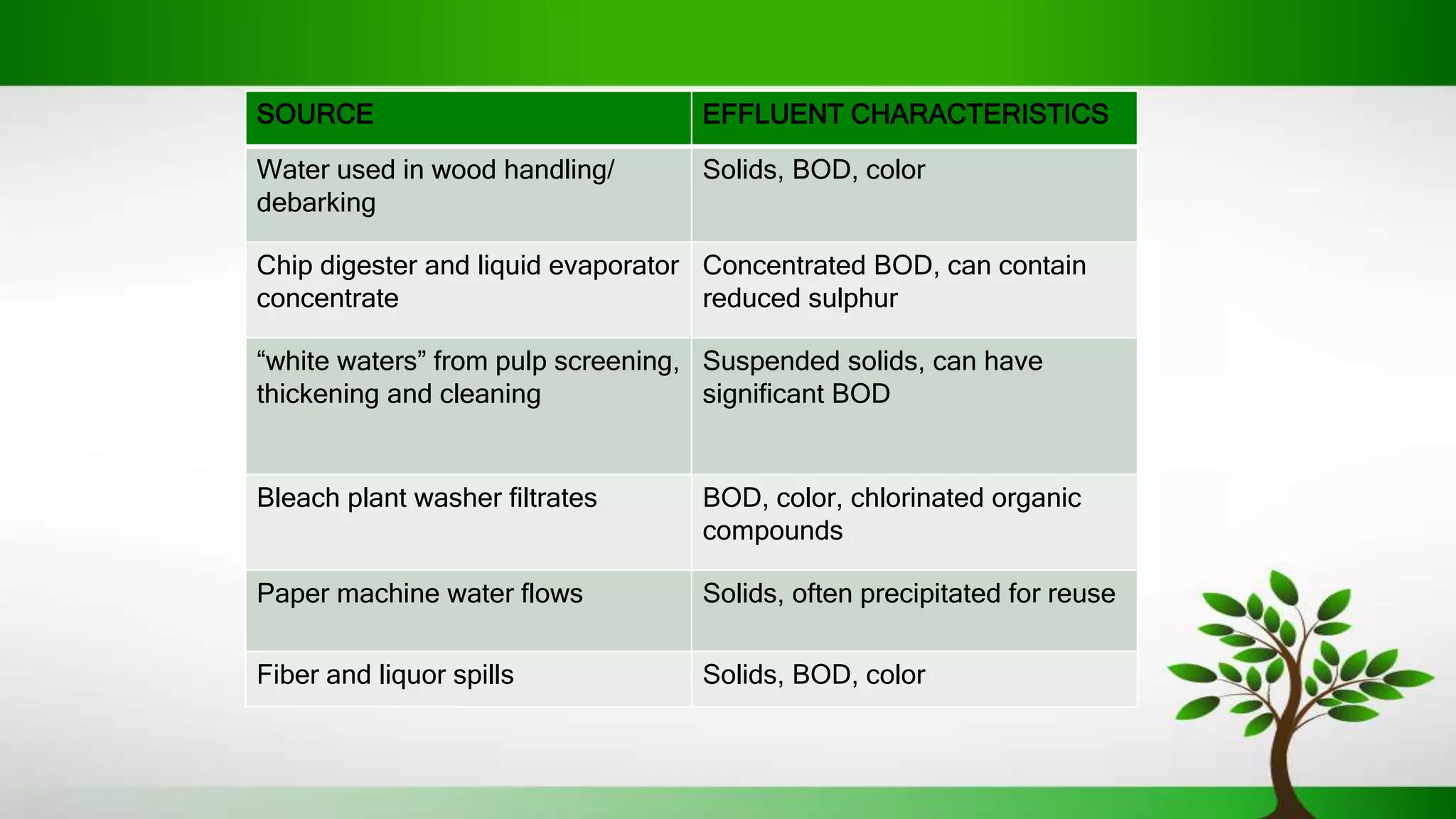

The document discusses the paper and pulp industry. It describes the key manufacturing steps including timber collection, de-barking, chipping, chemical and mechanical pulping processes, refining, and papermaking. It also discusses the treatment of waste from pulp mills. Effluents from pulp and paper mills contain high levels of solids, COD, BOD, color, and other pollutants. Treatment methods include screening, sedimentation, and biological treatments like anaerobic technology to break down organic pollutants.