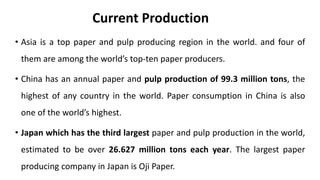

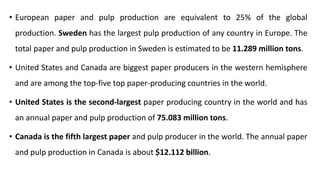

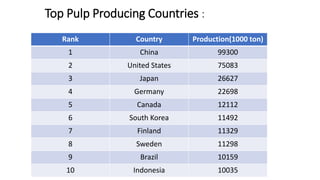

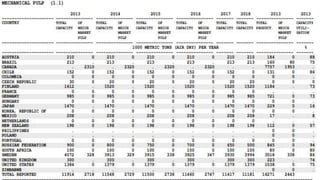

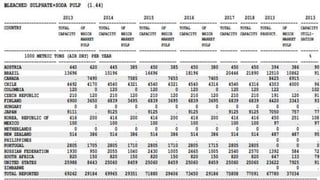

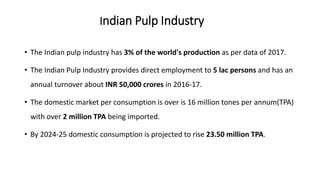

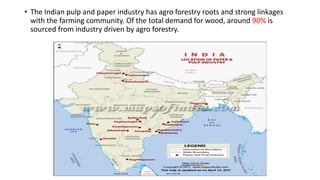

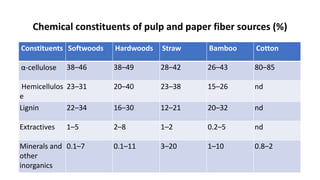

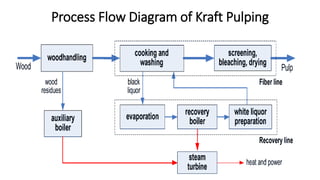

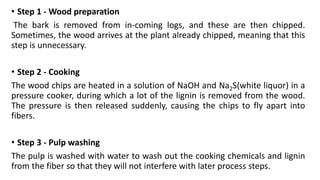

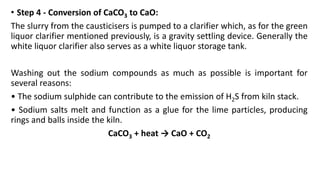

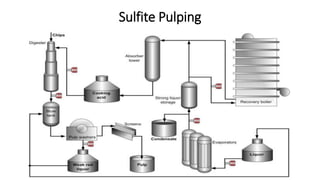

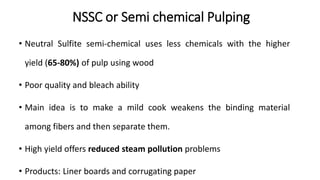

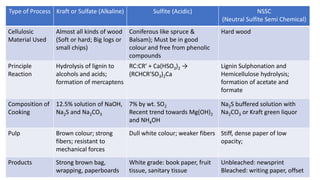

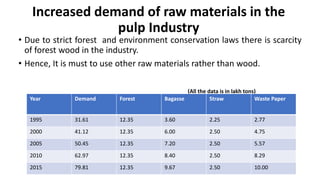

The document provides information about the pulp industry. It discusses the history and development of pulping processes like the kraft process. It details the current production of pulp globally and in countries like China, US, Japan, Canada, etc. It describes the key pulping processes of kraft, sulfite, and mechanical pulping. It also discusses utilities, engineering problems, use of different raw materials, energy usage, and recent advances as well as environmental issues in the pulp industry.