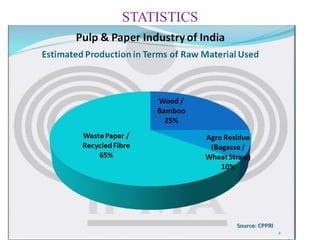

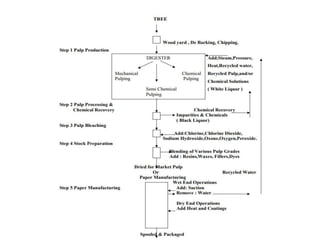

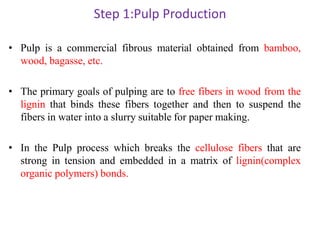

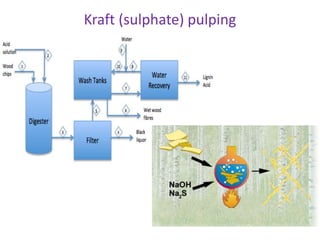

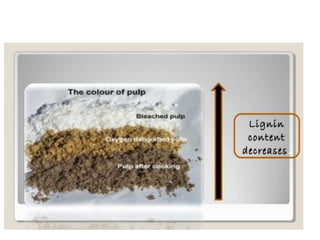

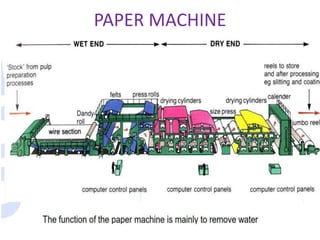

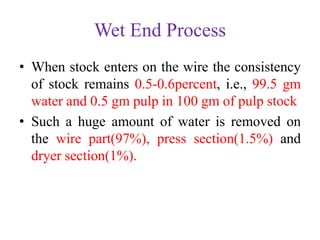

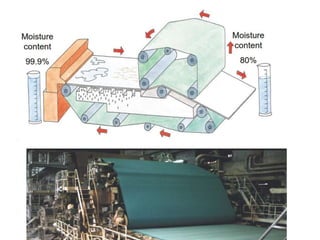

The document summarizes the key steps in the pulp and paper making process. It begins with harvesting raw materials like trees, bamboo, and recycled fibers. These materials are broken down into pulp via mechanical or chemical pulping processes. The pulp is bleached, processed, and formed into a paper sheet on a paper machine using a wire mesh. The wet sheet is pressed and dried into paper through subsequent processes before being calendered into its final form. The Indian paper industry produces about 3% of the world's paper from over 750 mills across the country.