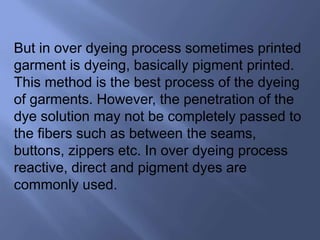

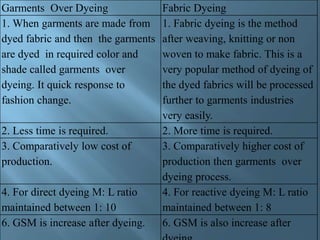

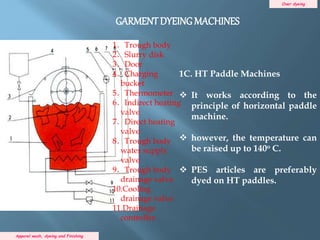

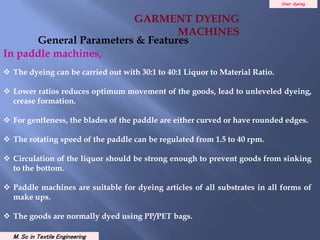

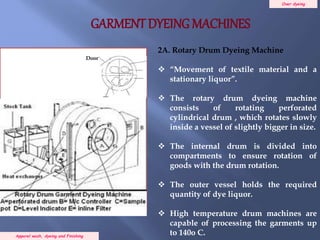

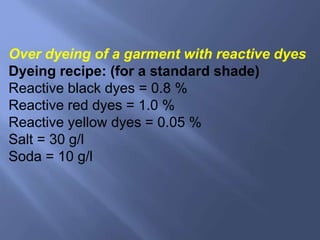

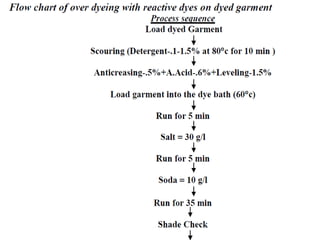

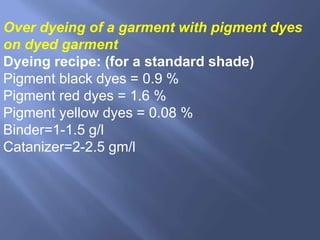

The document discusses garment dyeing, which involves dyeing fully fashioned garments after their manufacture, contrasting with fabric dyeing. It emphasizes the complexities and considerations in the over dyeing process, including selection of dyes, fabric, and accessories, while detailing the various types of dyeing machines used. It also outlines the importance of managing dye absorption and the impact of garment components on the dyeing process.