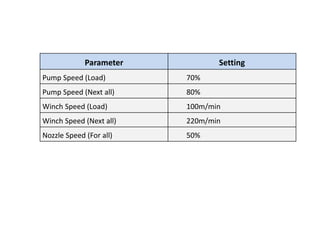

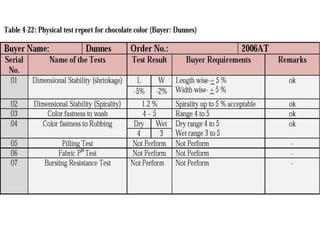

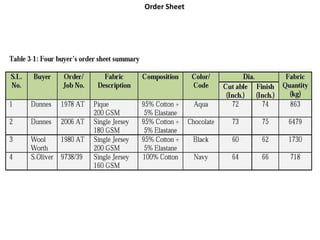

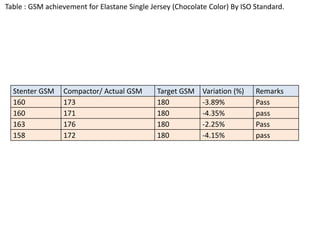

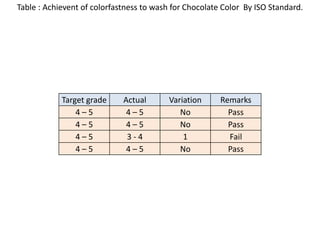

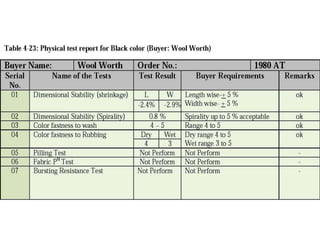

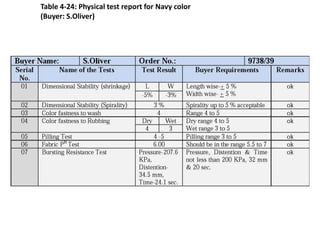

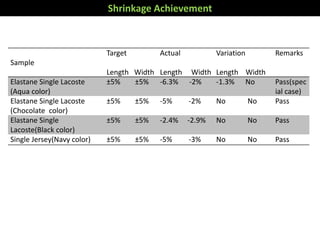

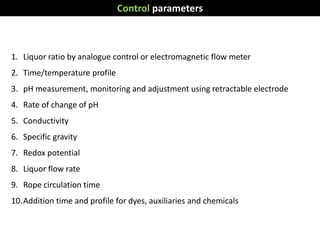

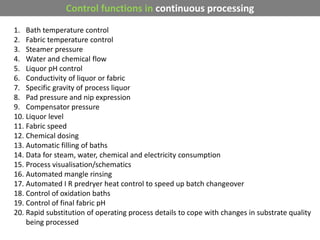

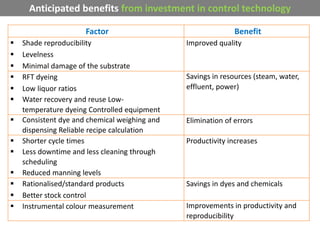

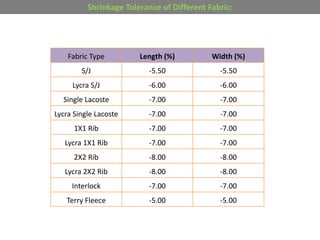

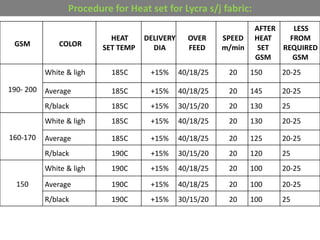

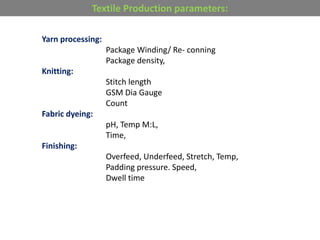

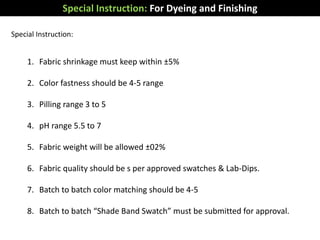

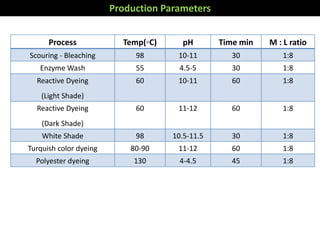

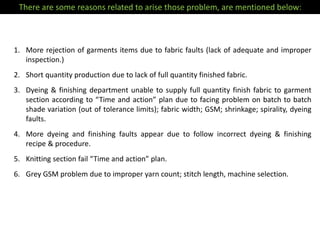

The document outlines key instructions and parameters for fabric processing in textile engineering, focusing on dyeing, finishing, and quality control practices. It specifies acceptable ranges for fabric characteristics such as shrinkage, color fastness, and pilling, as well as detailed procedures for various treatments and dyeing methods. Additionally, it emphasizes the importance of adhering to quality assurance measures to prevent production issues related to fabric quality and processing errors.

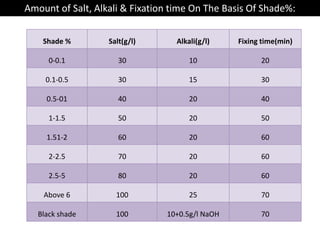

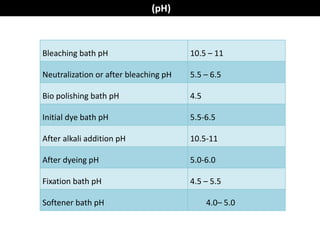

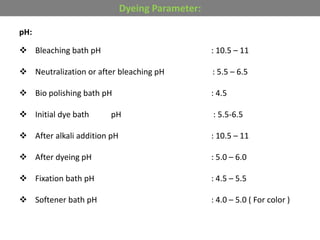

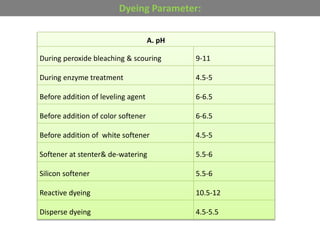

![Effects of pH:

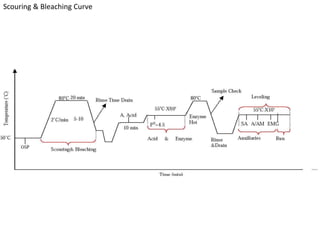

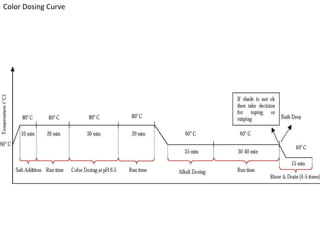

In the case of most popular fiber reactive dyes, a high PH actually activates the

cellulose (cot-ton) fiber, forming a cellulosed anion, which can then attack the

dye molecule, leading to a reaction that produces a strong, permanent covalent

bond. Without a high pH, the dye will not fix permanently to the cellulose fiber.

For this reason Sodium Carbonate (Na2CO3) [Some time mixed alkali such as

(NaOH + Na2CO3)] is used for no other reason than to increase the PH of the

dye reaction, so that the fiber will react with the dye. Basically during the color

addition, the PH of the bath remains at near about 6, but after adding alkali it

goes rise to pH 11.4 & this is the critical stage in which the dye molecules fix up

with the fiber.

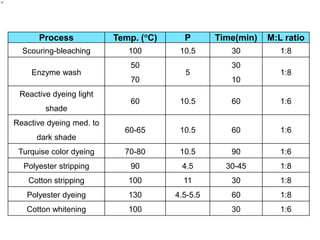

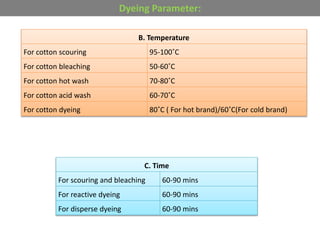

Effects of Time:

The time for dyeing also the vital one. A specific Time adjusted with the

temperature, very much needed for better dyeing. For this reason color dosing

takes place in 20 minutes (may vary process to process) & Specific run time is

set for dyeing.

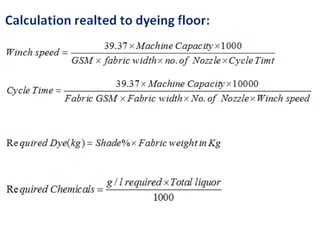

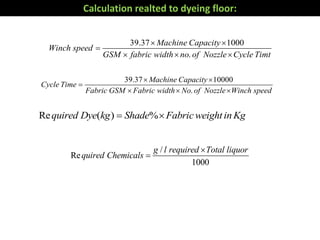

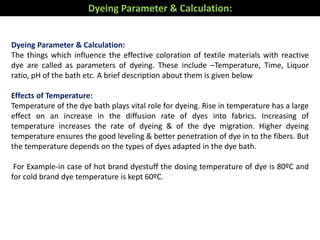

Dyeing Parameter & Calculation:](https://image.slidesharecdn.com/dyeingparameter-140802090708-phpapp02/85/Dyeing-parameters-19-320.jpg)