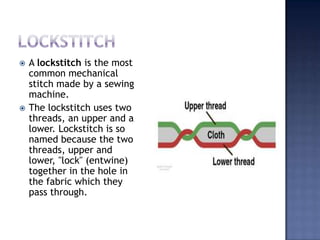

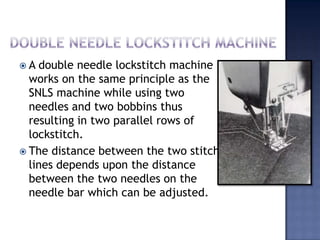

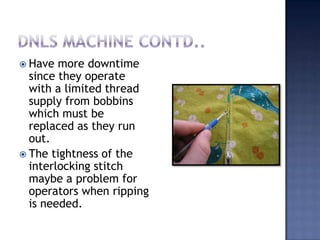

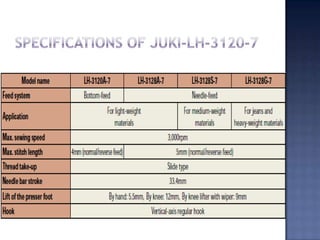

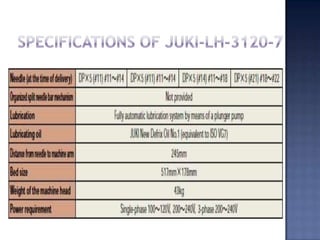

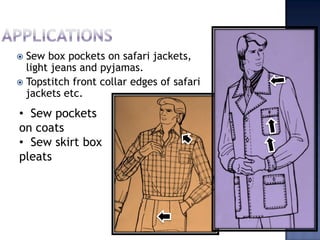

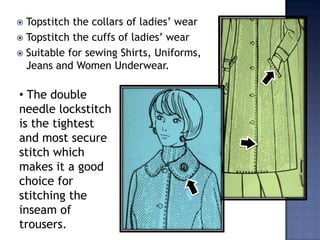

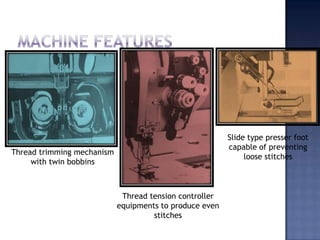

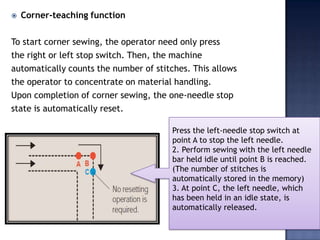

This document describes a double needle lockstitch (DNLS) machine. It begins by explaining the basic principles of a lockstitch and the components involved. It then discusses the two main types of lockstitch machines: single needle and double needle. The bulk of the document focuses on describing the specific features and applications of the Juki LH-3120-7 double needle lockstitch machine, including its specifications, advantages, additional features like corner teaching, and applications for sewing various garments.