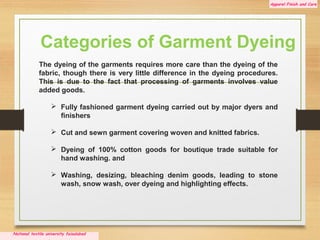

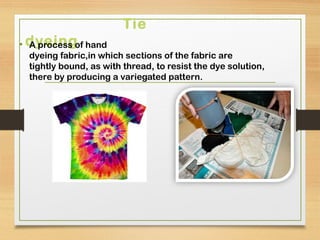

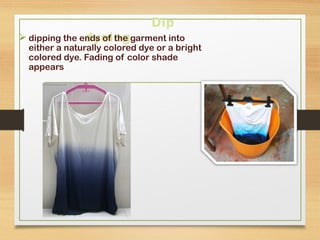

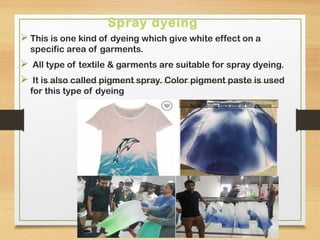

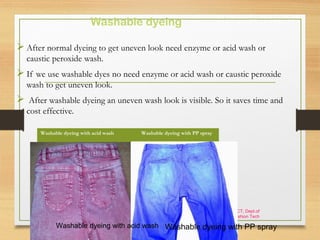

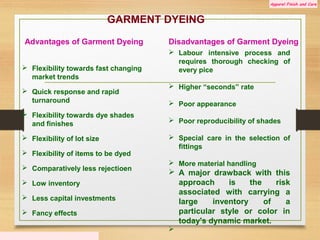

This document discusses garment dyeing, including the process, necessary preparations, equipment used, techniques, and advantages/disadvantages. It explains that garment dyeing involves dyeing fully constructed garments. Proper fabric and thread selection is important to ensure uniform dyeing and shrinkage. Common dyeing machines include paddle machines and rotary drums. Techniques include tie dyeing, dip dyeing, spray dyeing, and others. Garment dyeing allows for flexibility but has higher costs and quality risks compared to pre-dyed fabrics.