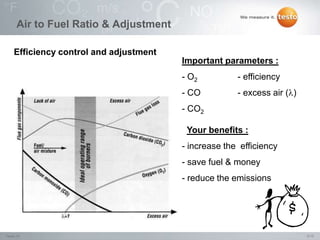

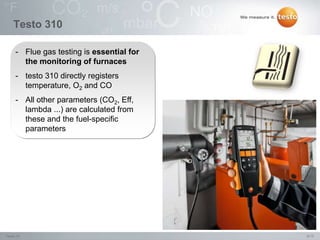

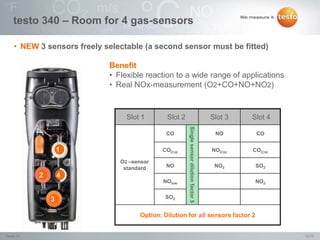

This document discusses the process of combustion and the importance of using a flue gas analyser to optimize combustion efficiency in boilers. It explains how excess air affects combustion and outlines key parameters for monitoring, such as O2, CO, and efficiency. Additionally, it presents various testo flue gas analysers, highlighting their features and benefits for proper combustion monitoring and energy savings.