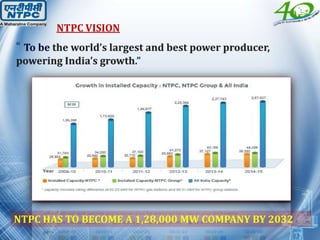

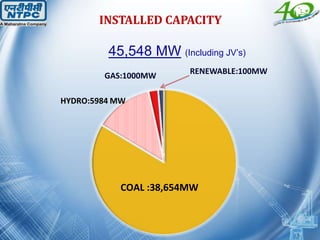

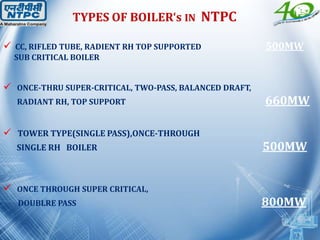

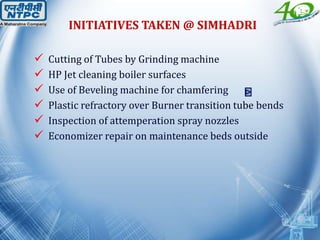

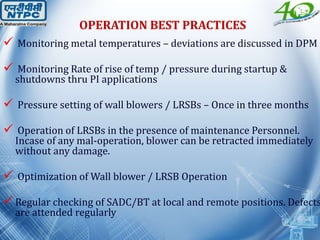

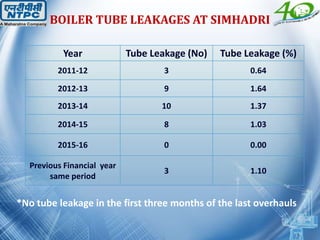

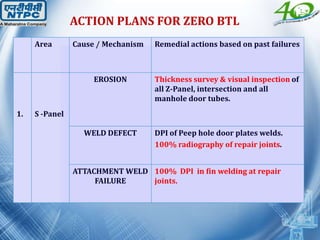

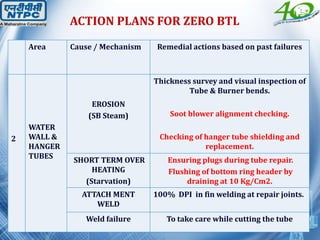

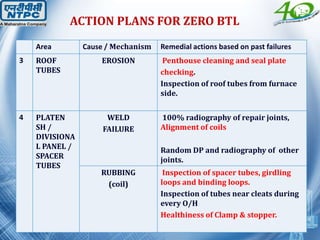

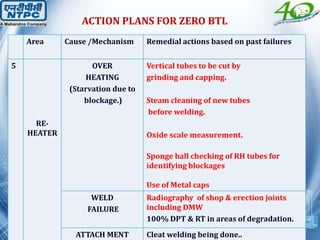

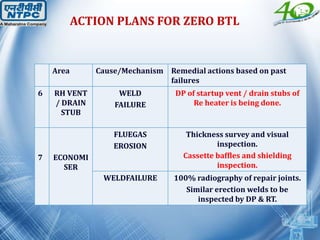

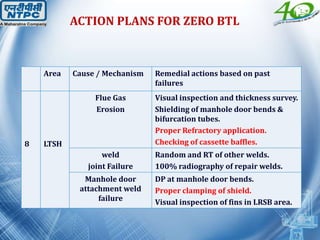

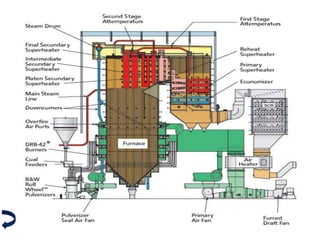

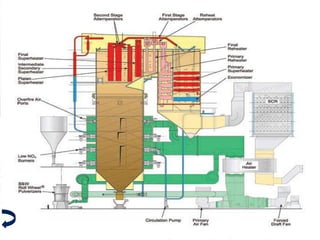

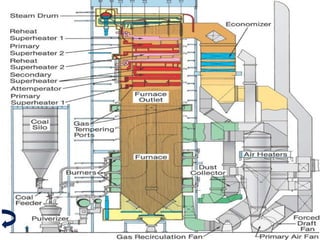

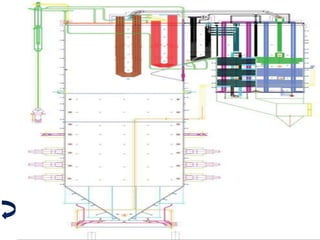

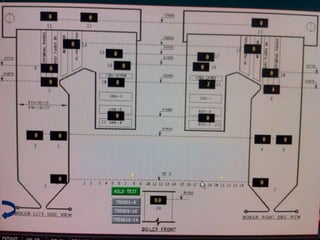

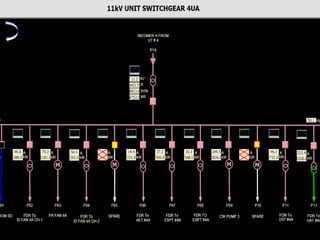

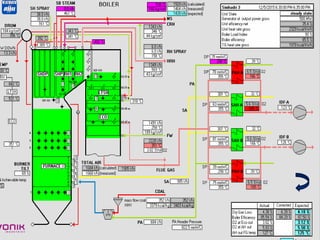

The document discusses efficient operation and maintenance of boilers at NTPC Simhadri. It provides an overview of NTPC's journey and capacity, describes the types of boilers used, and outlines best practices adopted to reduce boiler tube leakages. These include improved startup procedures, monitoring of chemical parameters, thorough inspections and testing, and implementation of new technologies like acoustic leak detectors and process instrumentation systems. The presentation aims to share experiences in achieving zero boiler tube failures through preventative maintenance practices.