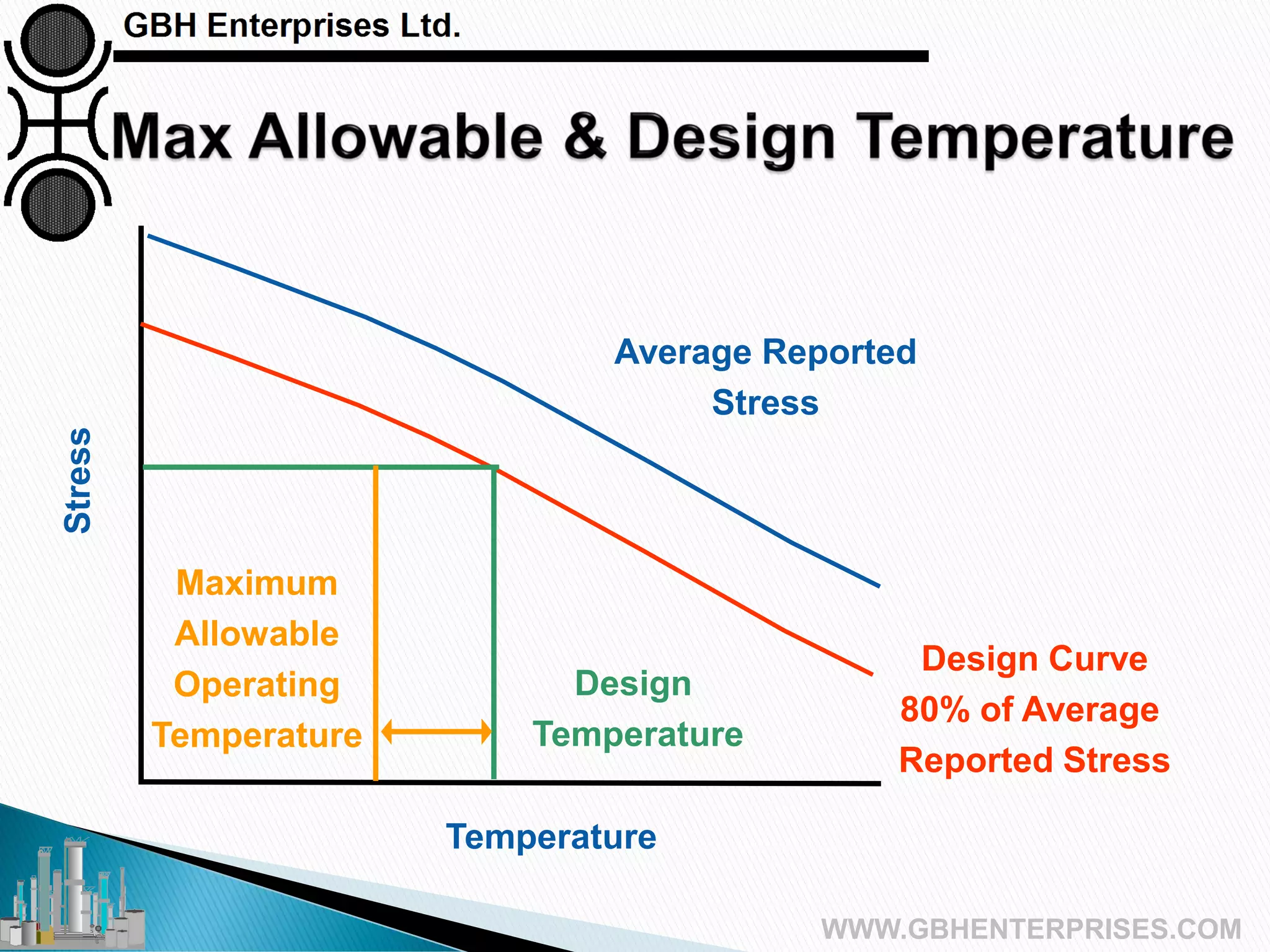

This presentation covers steam reforming tube design, focusing on principles, manufacturing, failure mechanisms, and inspection techniques. It emphasizes the importance of the Larson-Miller parameter for predicting material performance at varying temperatures and stresses, and discusses advancements in tube materials and welding techniques. Additionally, it outlines various inspection methods, including non-destructive testing, to assess tube integrity and life expectancy.