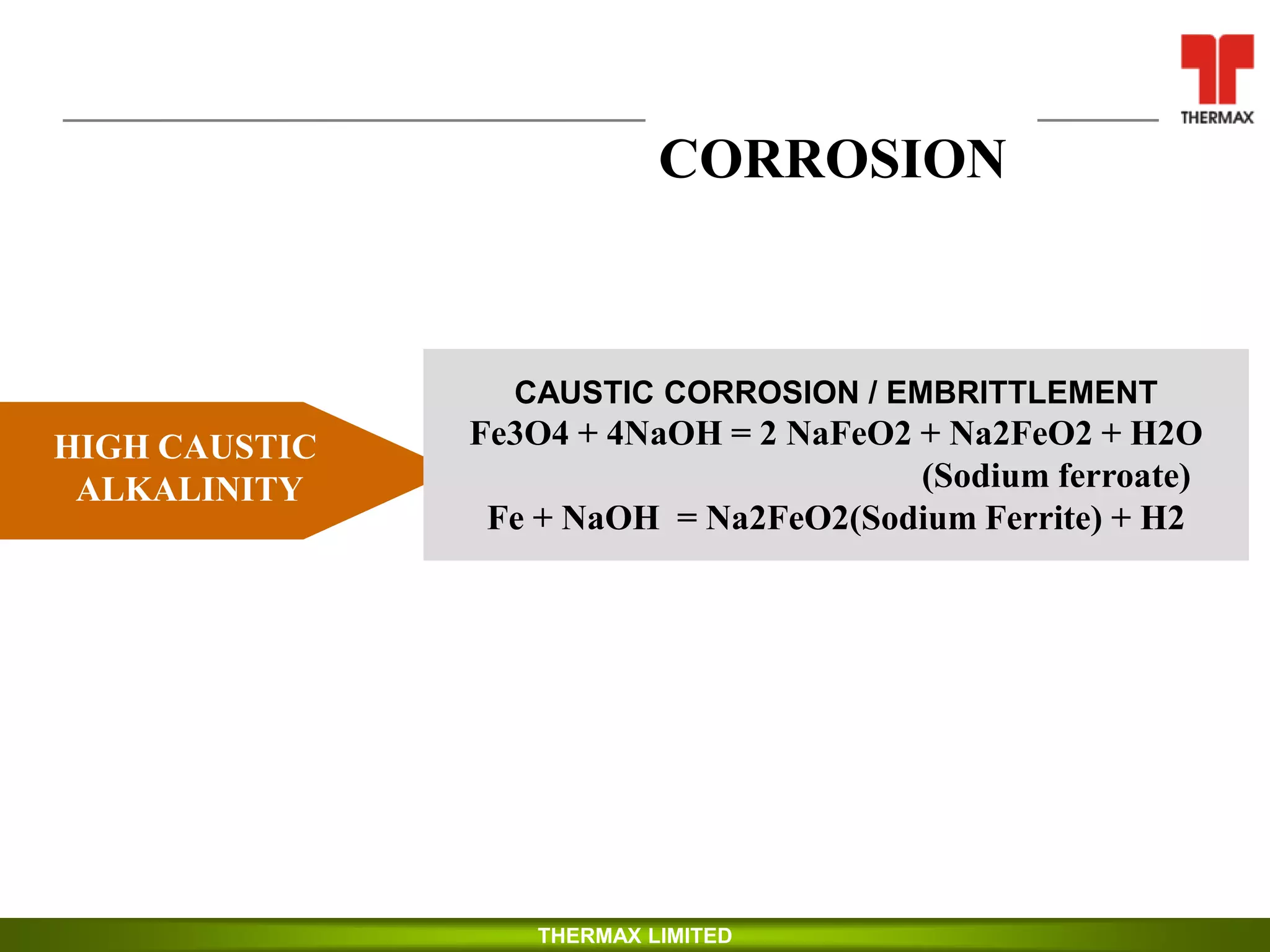

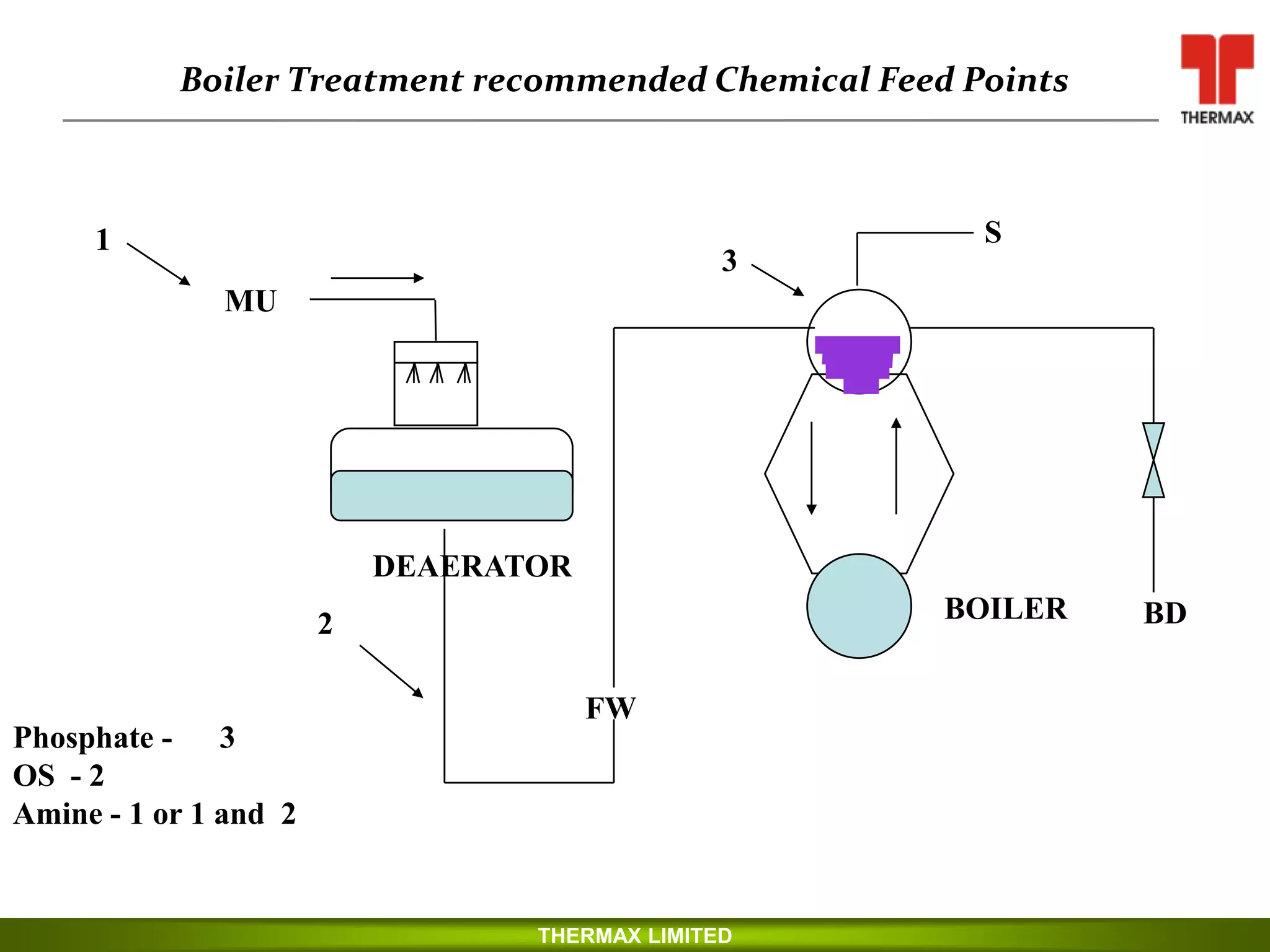

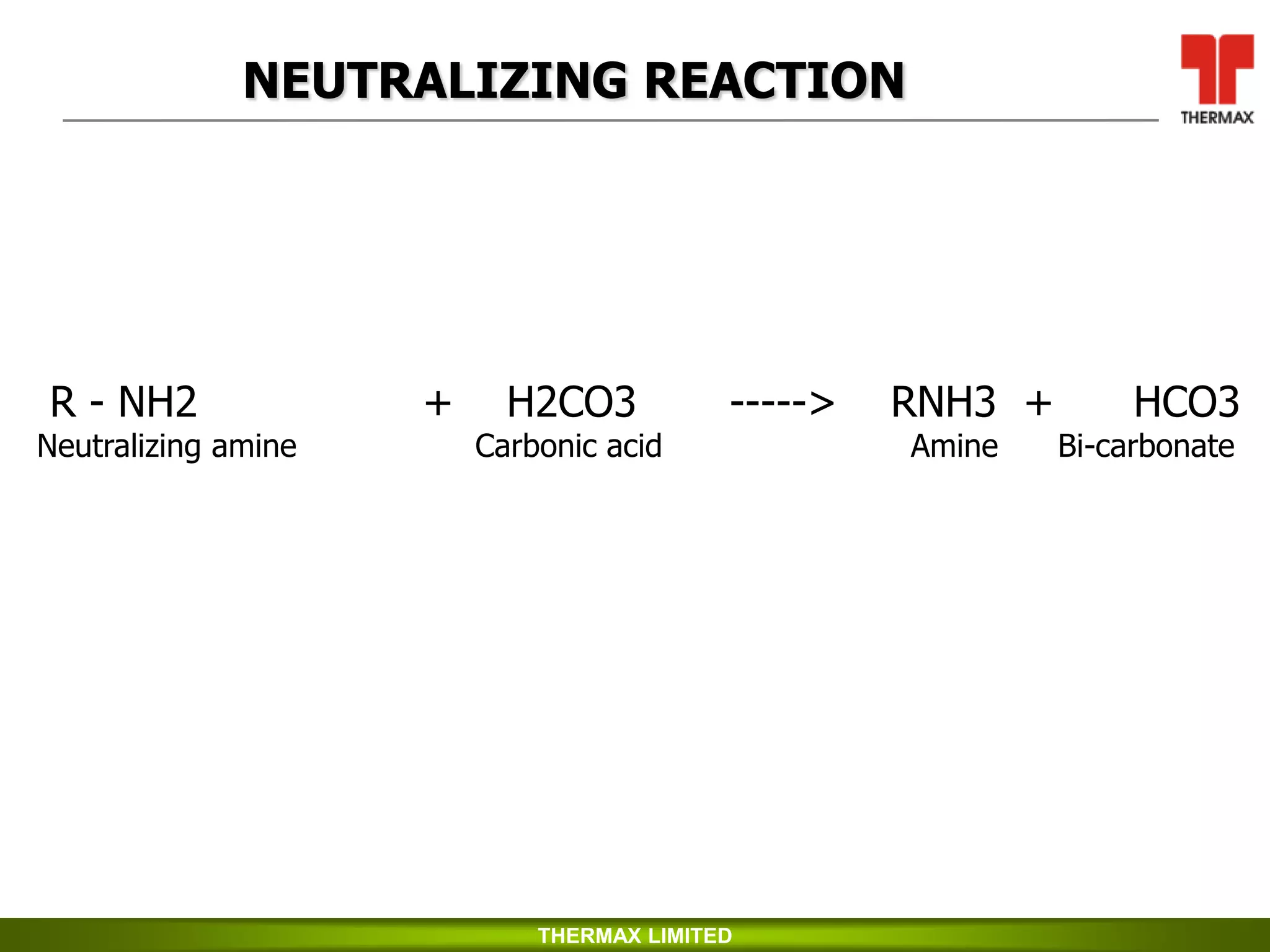

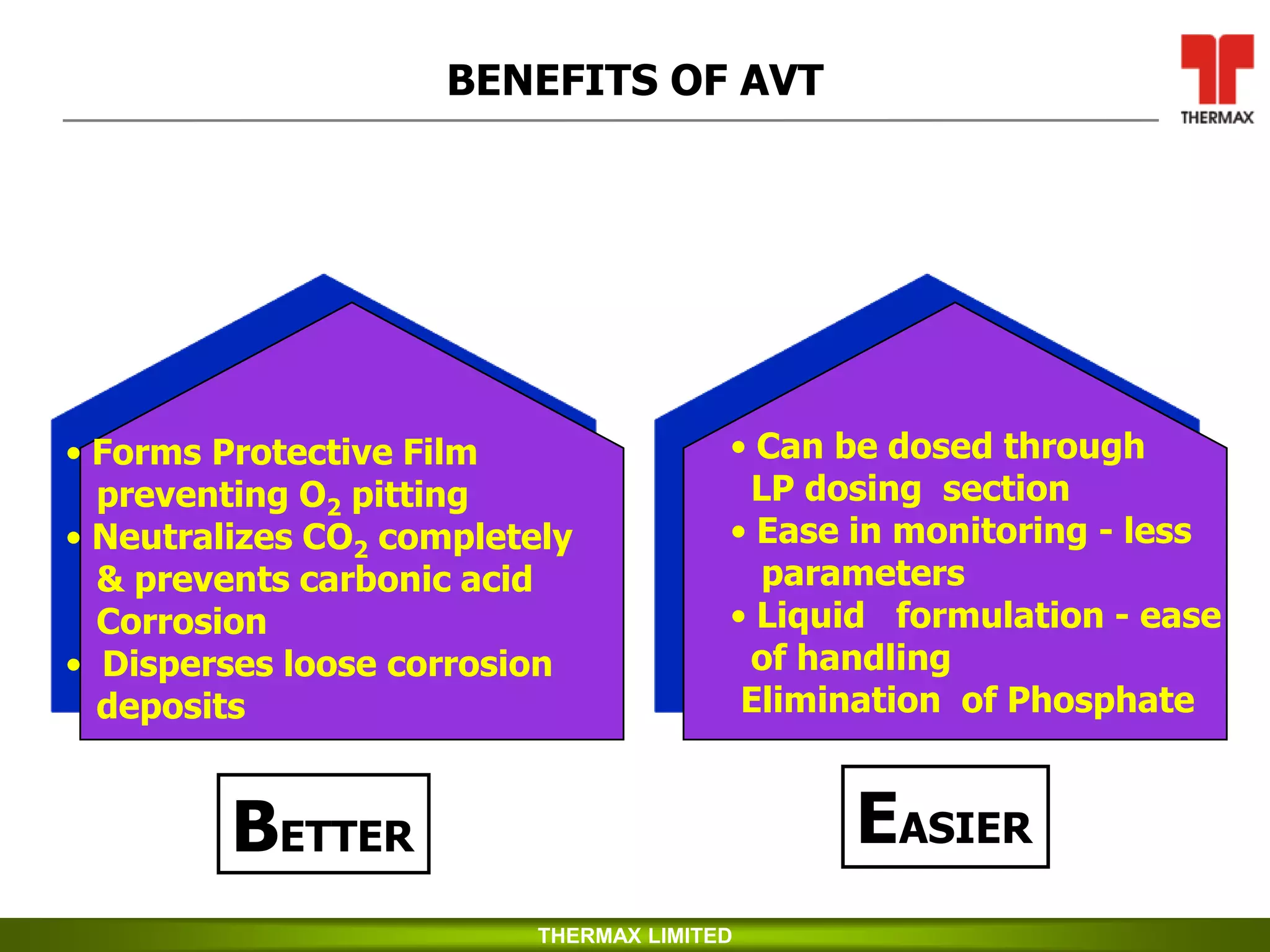

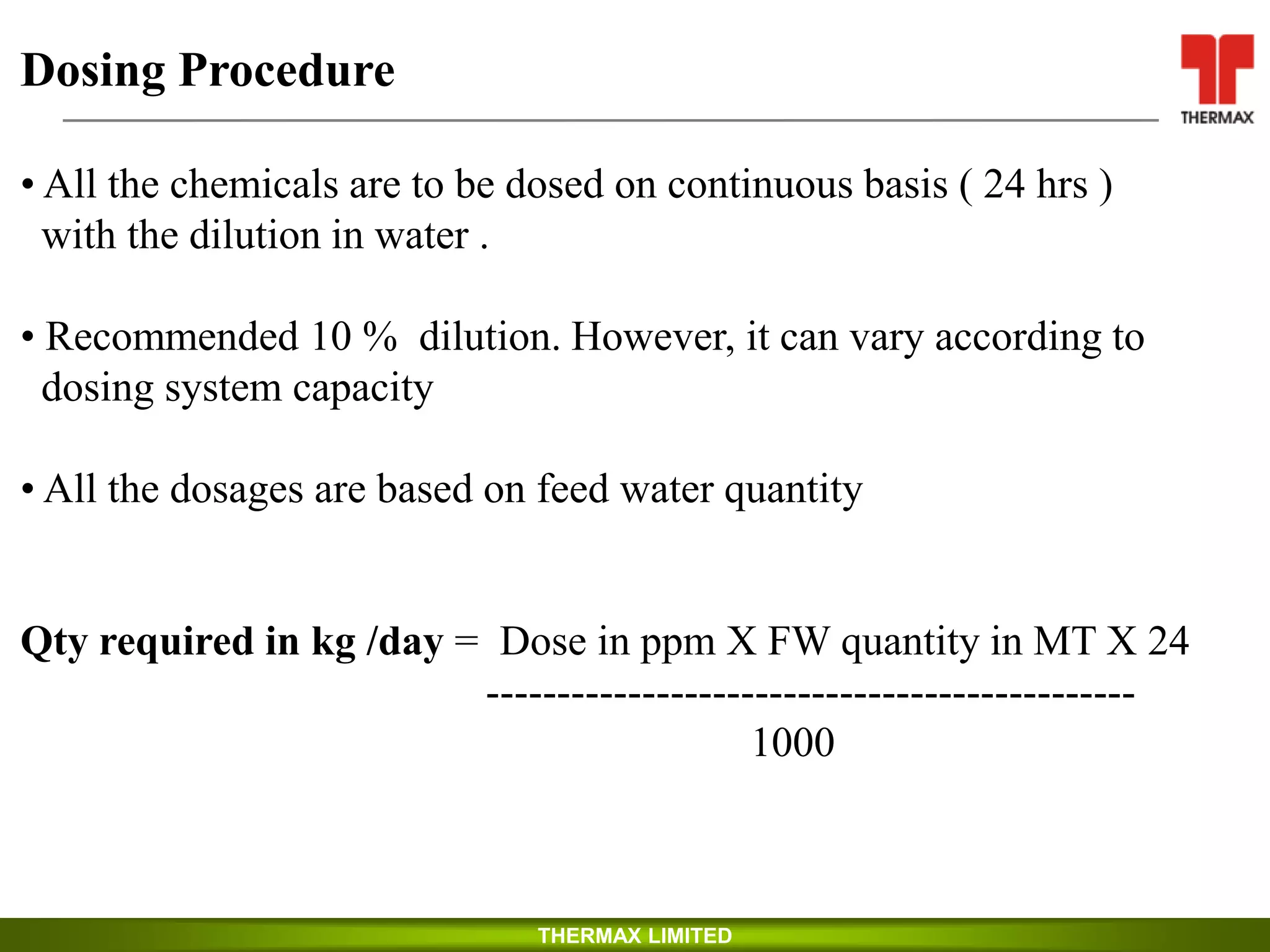

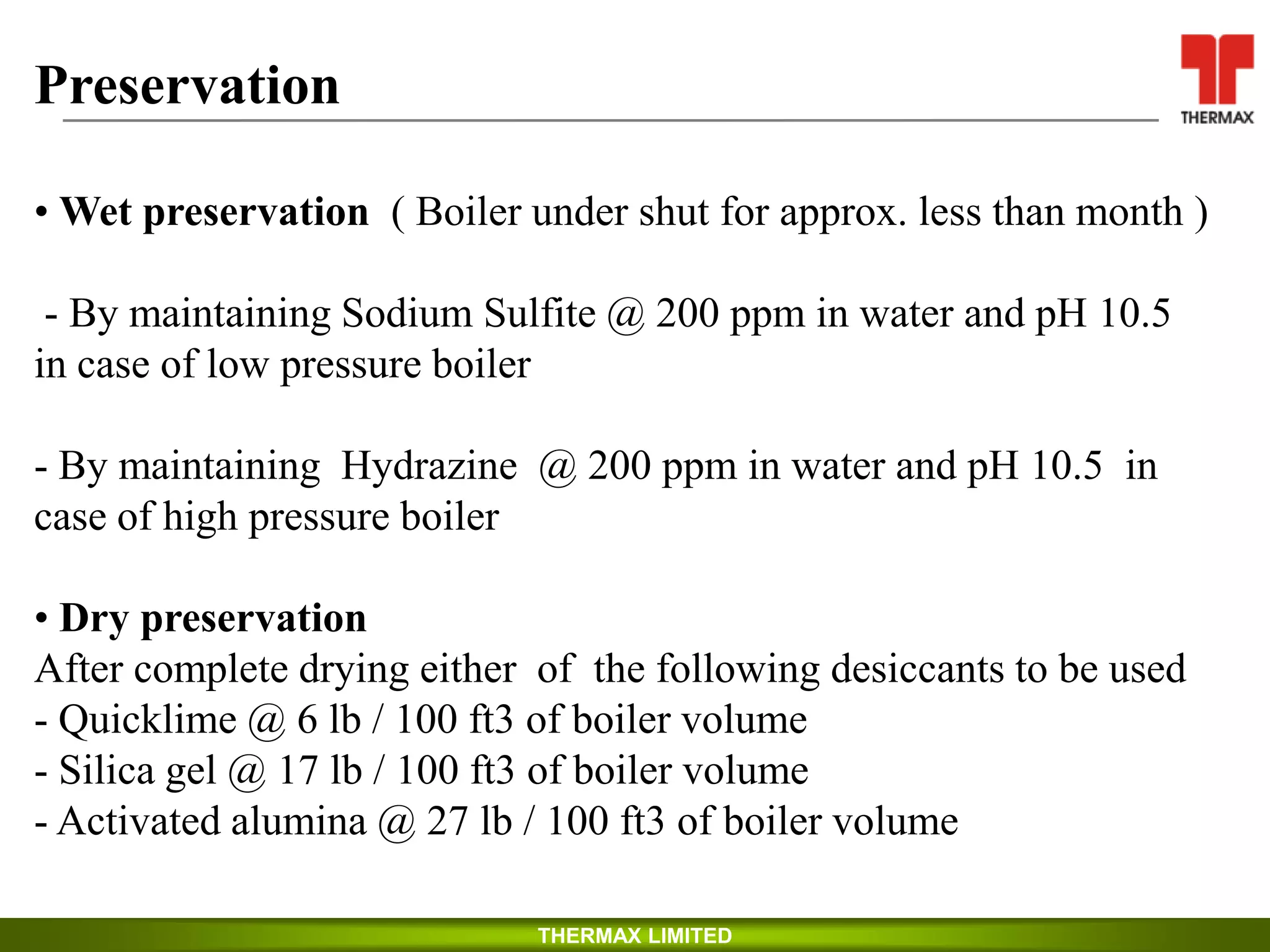

This document discusses boiler water treatment from Thermax Limited. It covers water chemistry issues like scaling, corrosion and carryover and their causes. It describes different treatment programs like phosphate, amine and oxygen scavenger dosing. Key steps of treatment include chemical dosing, monitoring water parameters, and preservation during shut down. The objective is to maintain water quality, prevent equipment damage, and ensure reliability and efficiency.