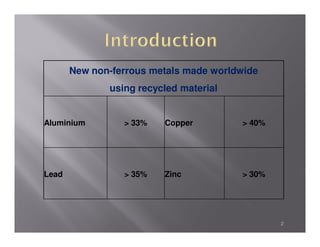

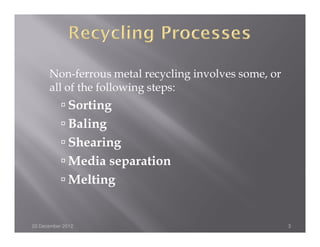

The document discusses the recycling of non-ferrous metals such as aluminum, copper, lead, and zinc, highlighting their significant energy savings and environmental benefits. It details the recycling processes, applications, and the high recycling rates of these metals, emphasizing how aluminum recycling can save substantial resources and energy. Additionally, it mentions the recycling value of copper and lead, showcasing the extensive potential for reuse in various industries.