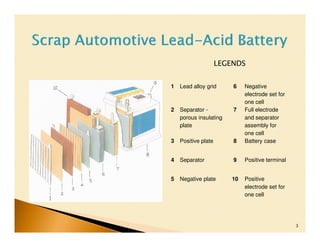

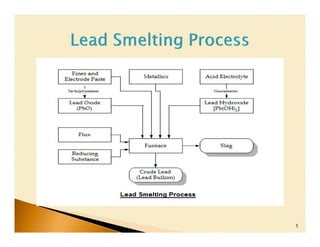

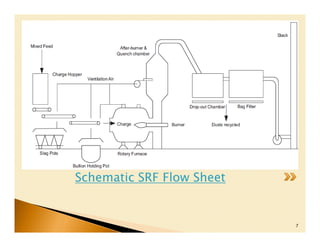

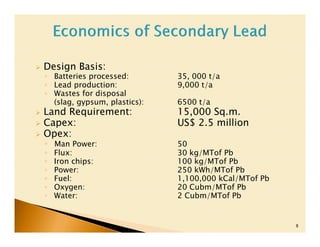

The document describes the process for recycling scrap automotive lead acid batteries. Batteries are cut apart, with polypropylene pieces collected and washed for resale. Lead components are cleaned and smelted in furnaces, with molten lead poured into ingots for reuse in new batteries. Sulfuric acid is neutralized into water or processed into sodium sulfate for industrial uses. Lead smelting processes use equipment like blast furnaces or rotary kilns. A schematic flow sheet shows the recycling plant design, which can process 35,000 tons of batteries annually to produce 9,000 tons of lead ingots.