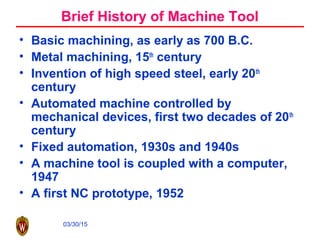

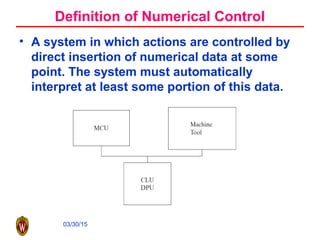

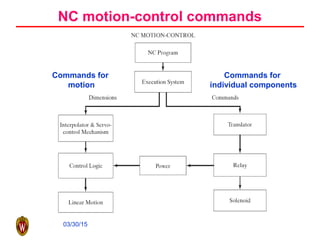

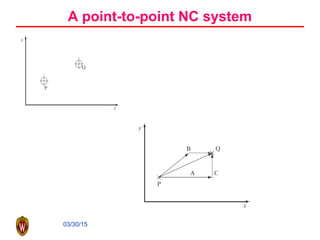

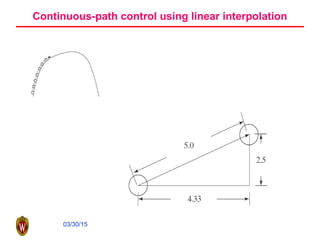

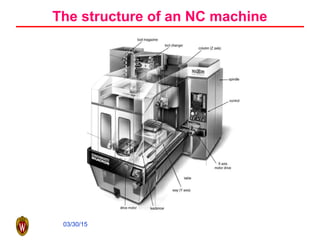

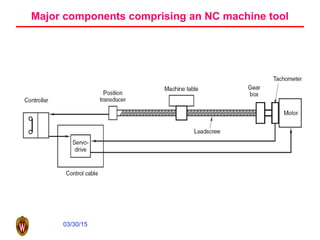

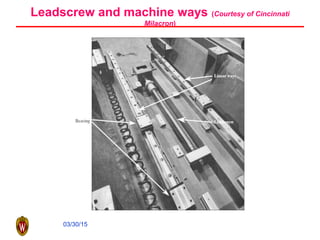

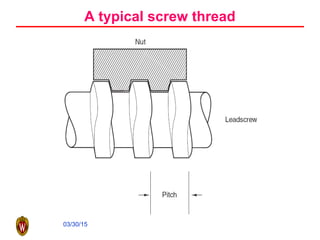

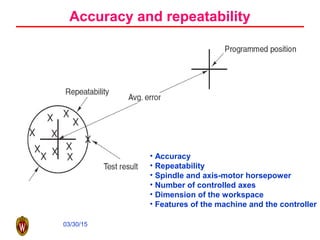

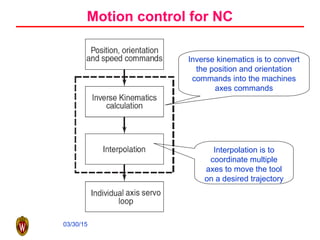

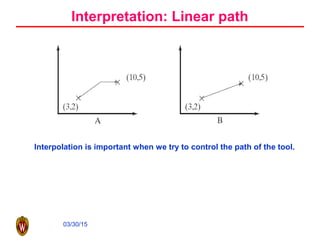

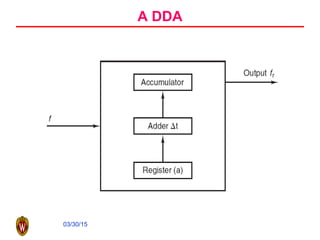

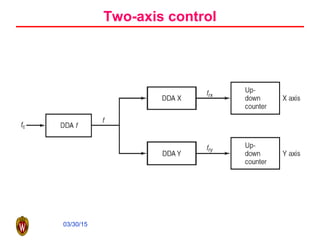

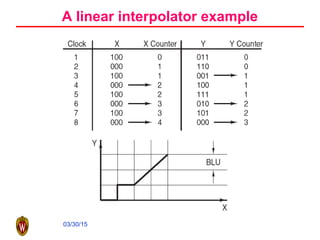

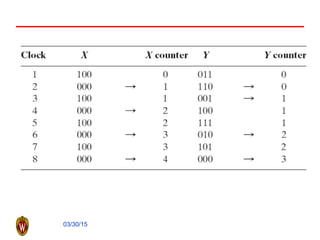

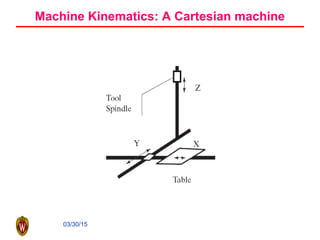

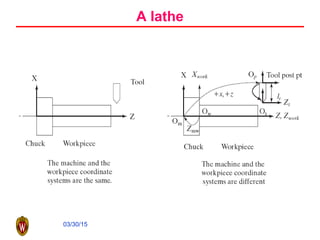

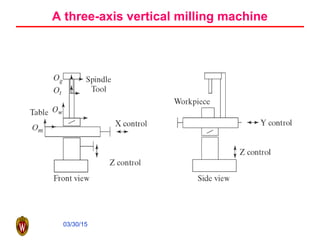

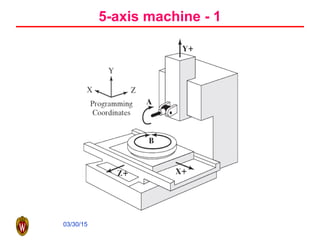

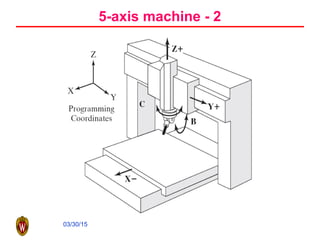

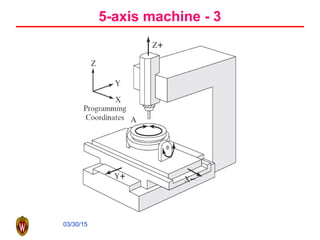

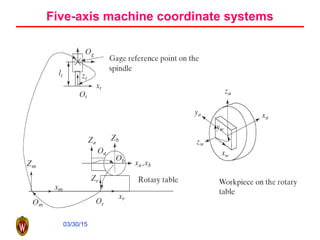

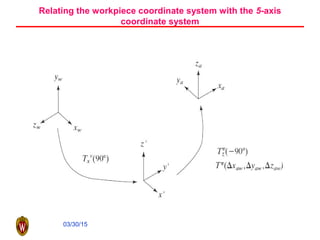

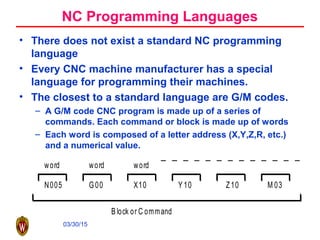

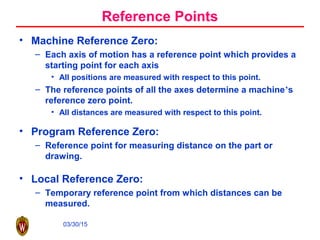

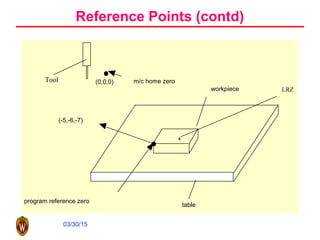

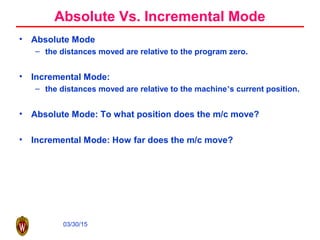

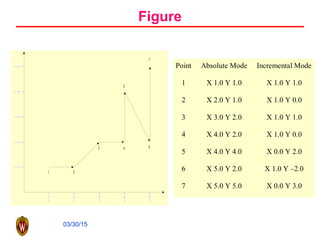

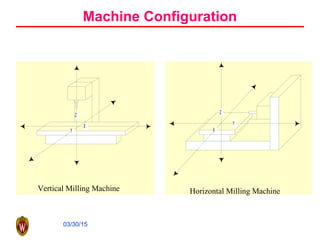

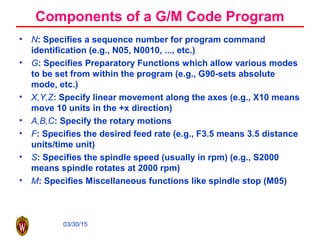

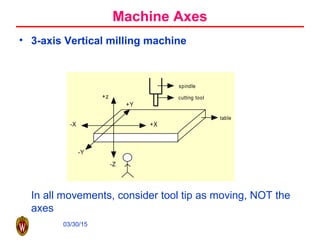

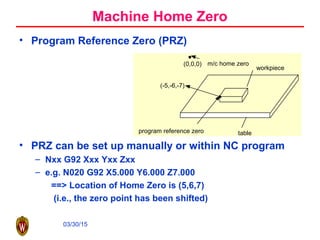

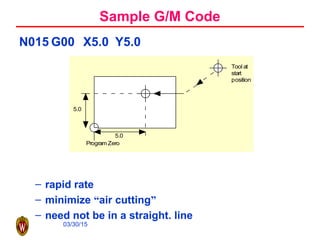

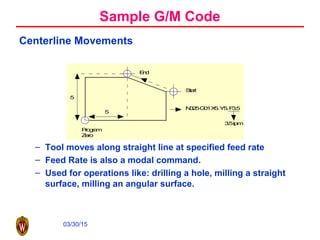

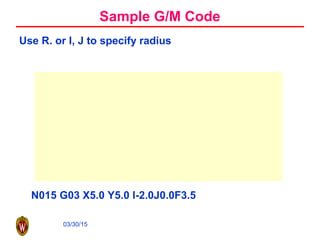

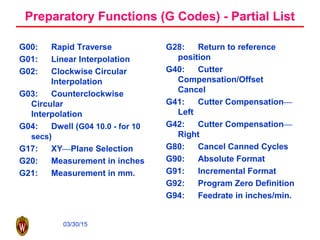

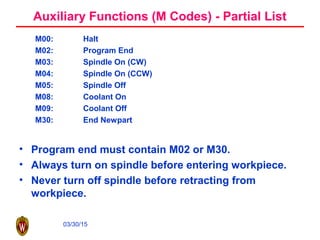

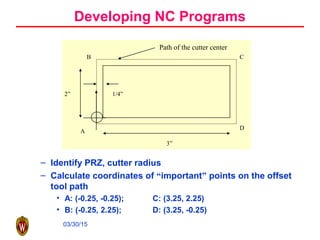

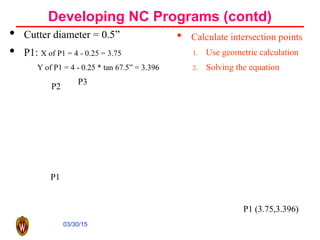

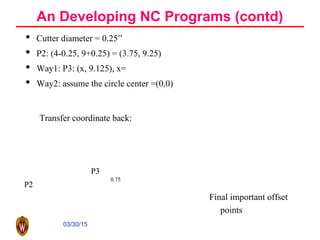

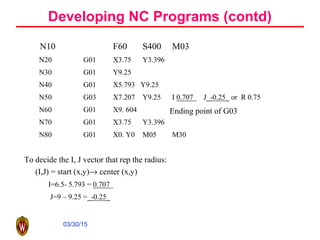

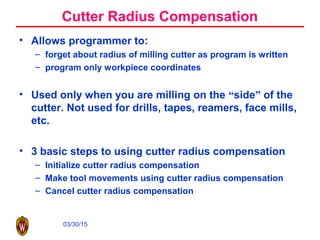

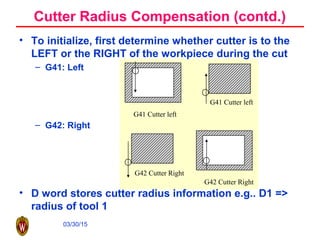

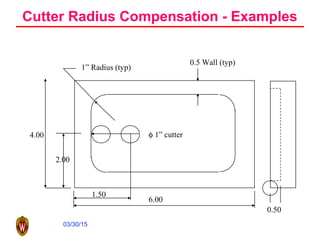

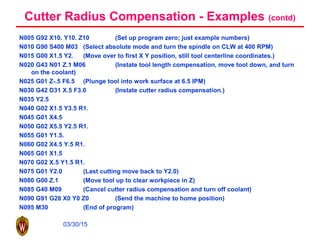

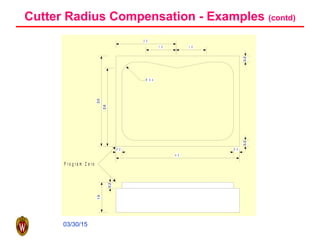

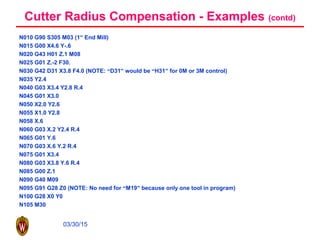

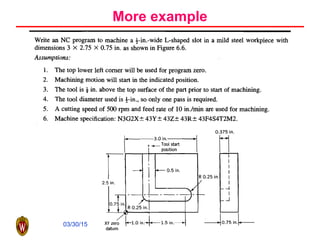

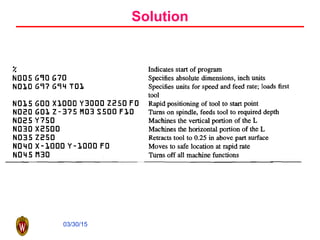

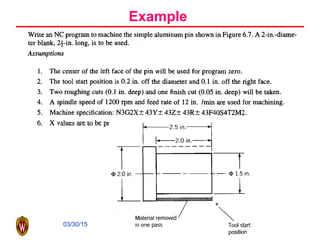

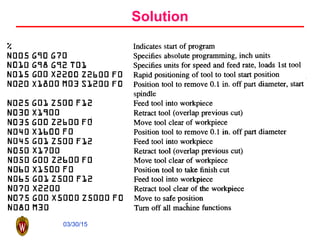

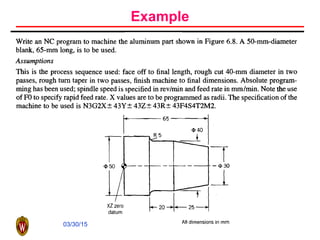

The document discusses numerical control and programming for machine tools. It provides a brief history of machine tools and NC systems. It defines numerical control and describes various NC motion control commands, classifications of NC systems, and components of an NC machine tool. The document outlines point-to-point and continuous path control, linear and circular interpolation, accuracy and repeatability considerations, and the structure and major components of an NC machine. It also covers NC manual programming languages, reference points, absolute and incremental modes, and examples of G and M code programming for cutter radius compensation.