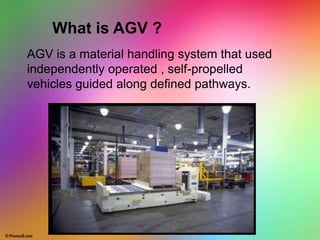

AGVs are mobile robots that use markers, wires, vision, magnets or lasers to navigate around facilities like manufacturing plants and warehouses. They can tow objects or store them to move materials autonomously. AGVs are used across many industries to transport items between areas. Some key advantages of AGVs include reduced labor costs, flexibility, reliability and lower long-term investment compared to other transport methods. They are well-suited for repetitive pallet handling and gentle finished goods movement applications.