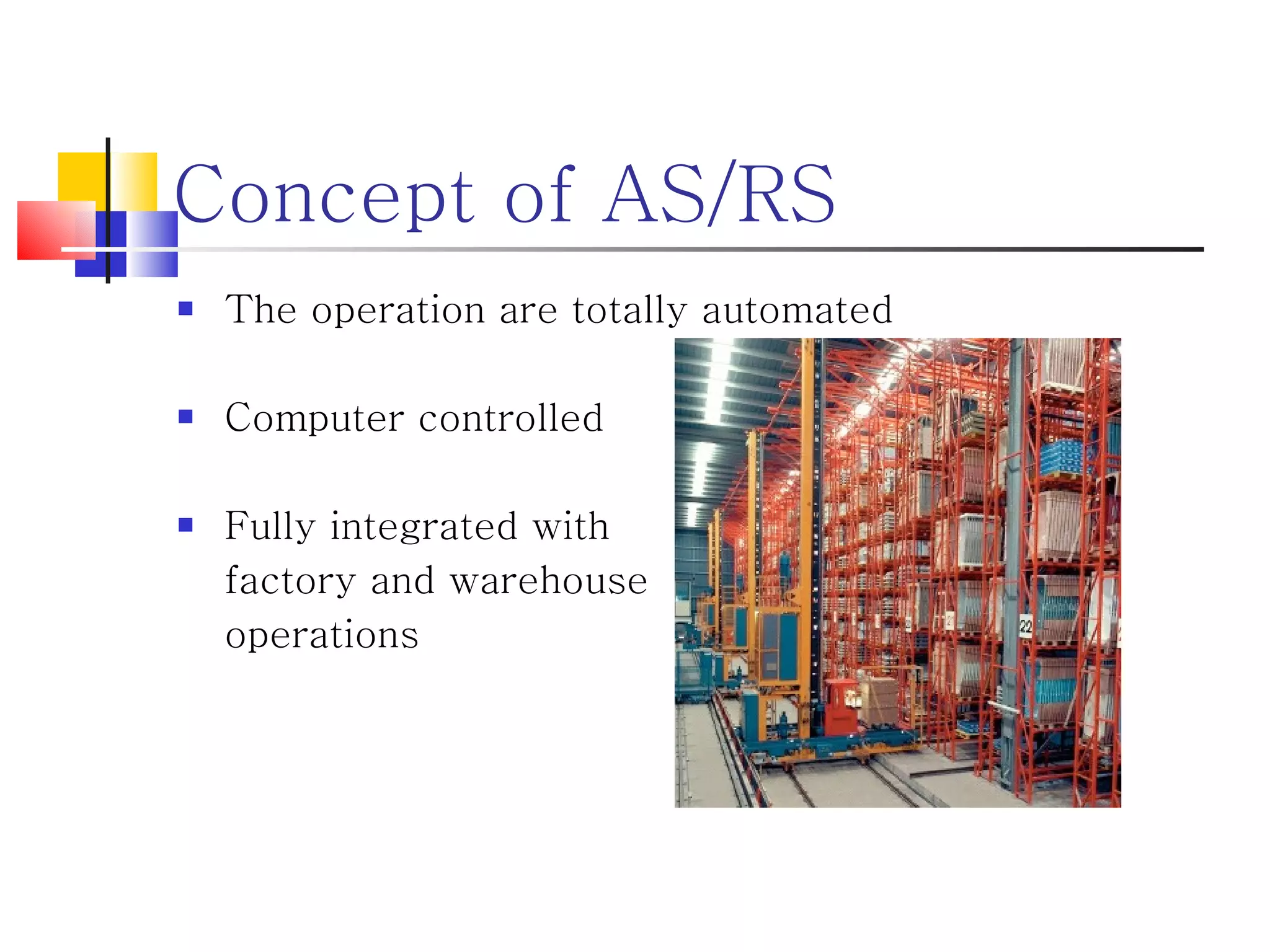

The document provides an overview of automated storage and retrieval systems (AS/RS). It discusses the problems with conventional storage systems, the concept and basic structure of AS/RS, including storage racks, storage/retrieval machines, storage modules, and pick-and-deposit stations. It also covers the control system using computers and positioning methods, as well as the benefits of AS/RS such as improved efficiency, accuracy, and inventory control. An example of FedEx using AS/RS is given.