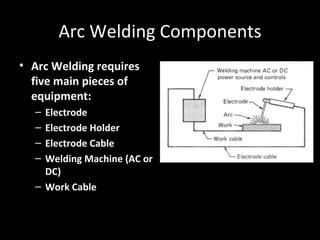

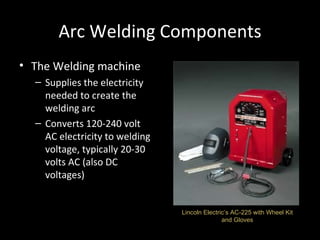

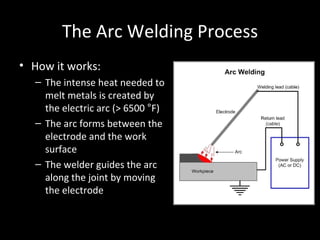

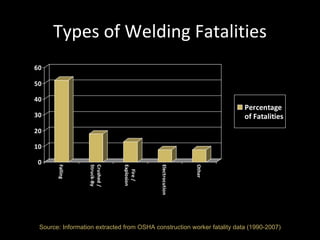

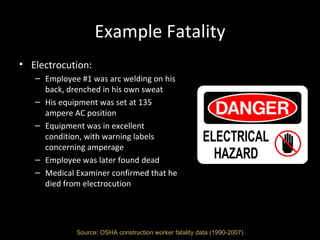

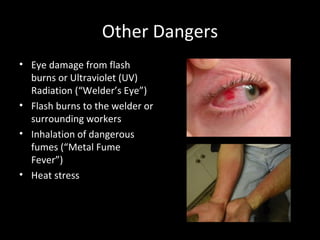

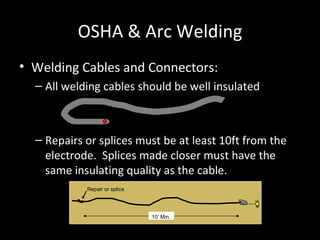

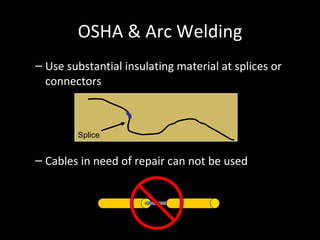

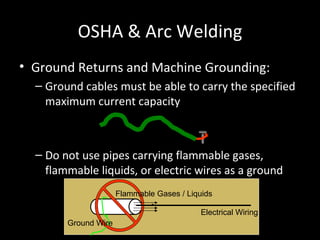

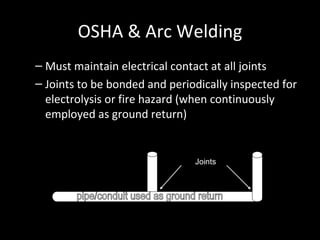

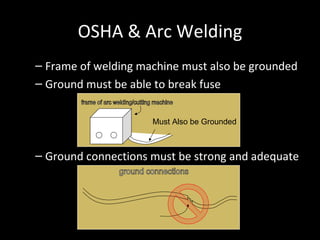

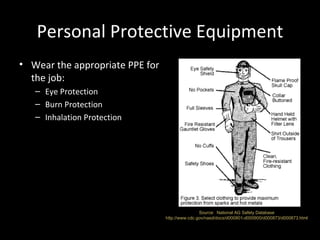

Arc welding is a process that joins metals through intense heat. It requires equipment like an electrode, electrode holder, welding machine and cables. Hazards include falls, crushing injuries, fires/explosions, and electrocution. Proper safety equipment like eye protection and barriers are needed, as well as ensuring a safe work environment and properly maintained welding equipment.