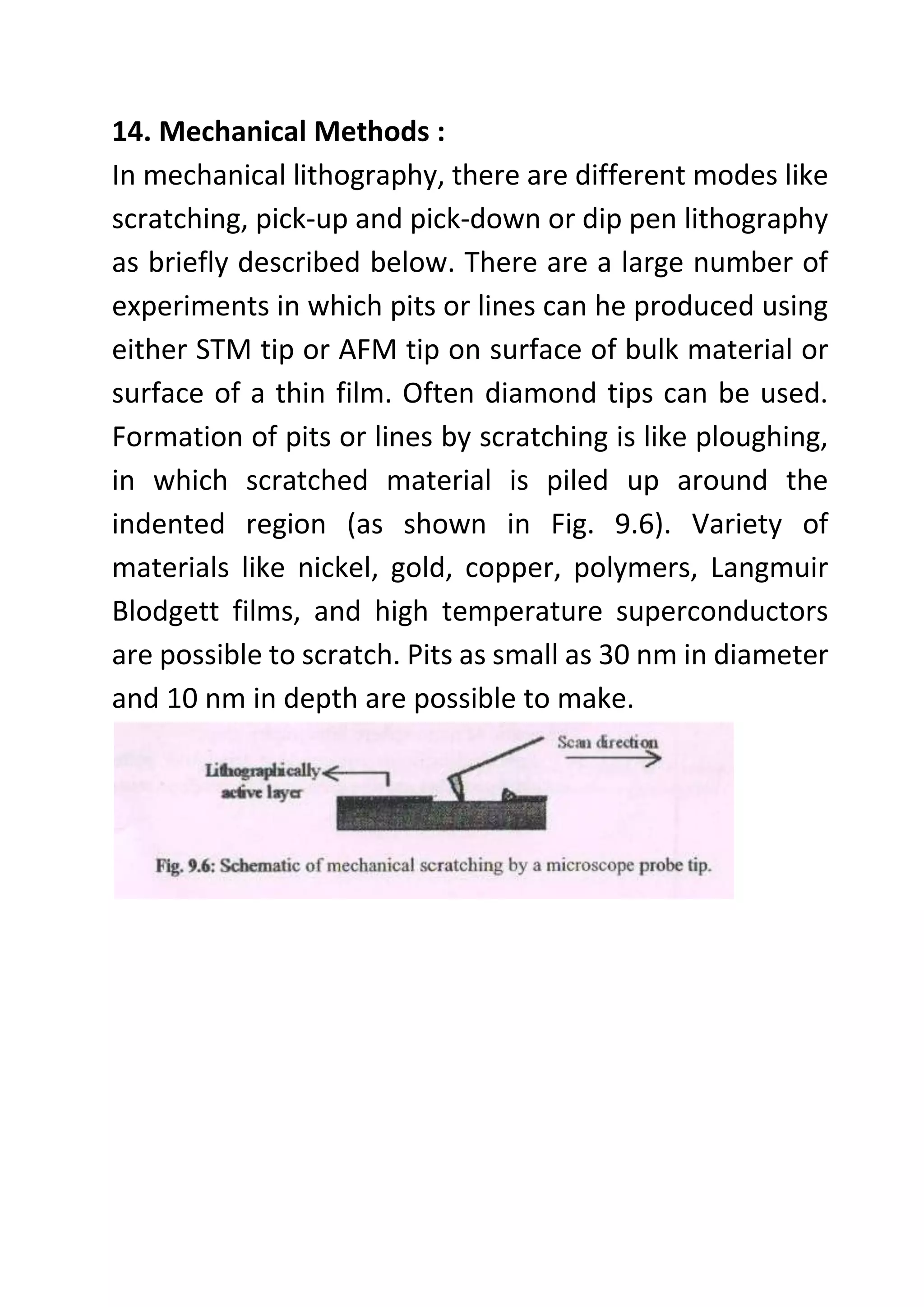

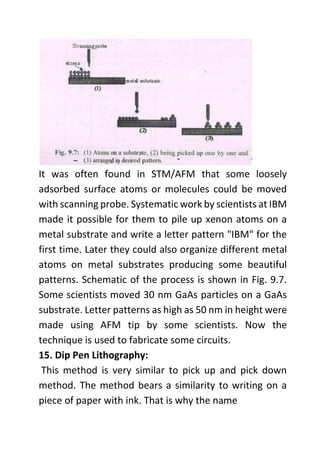

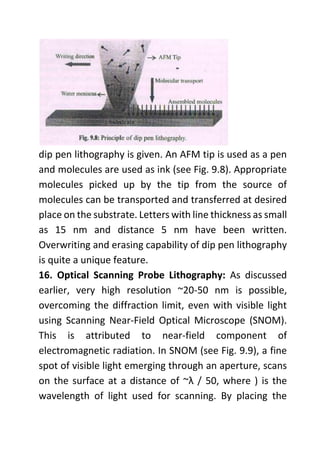

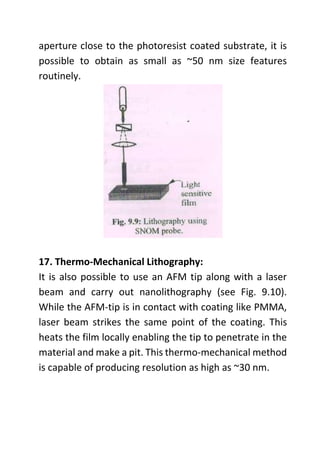

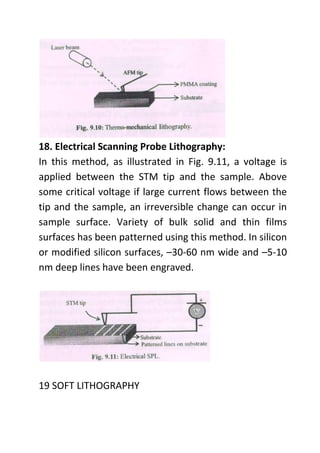

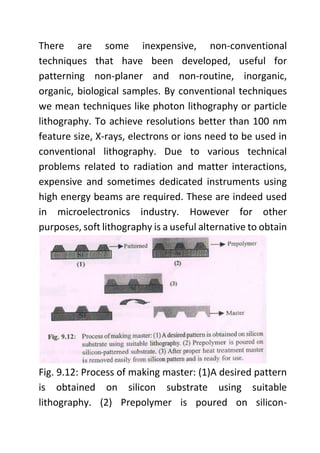

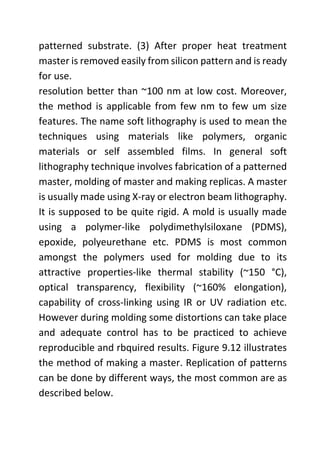

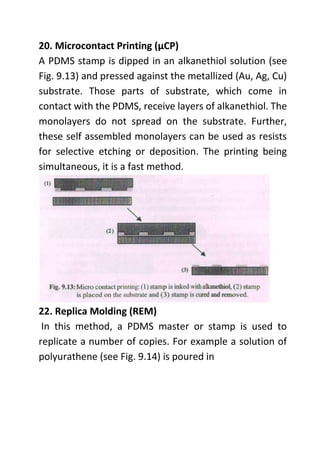

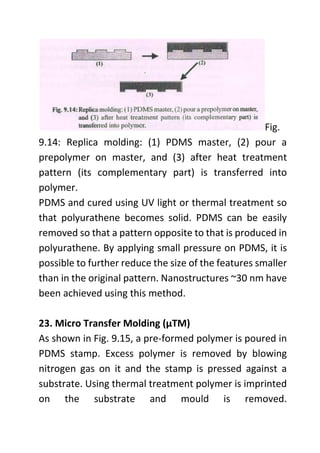

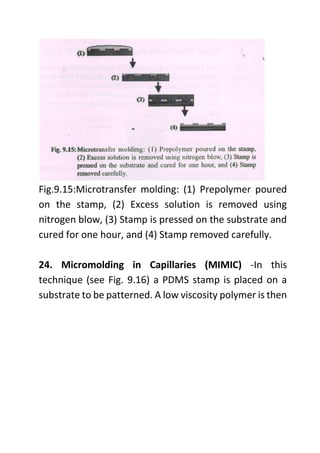

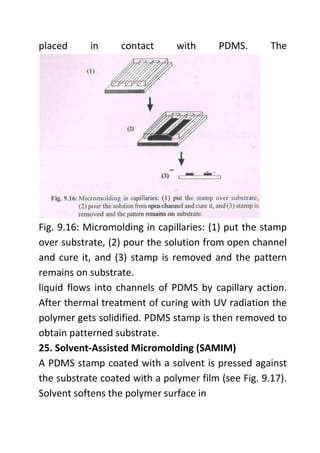

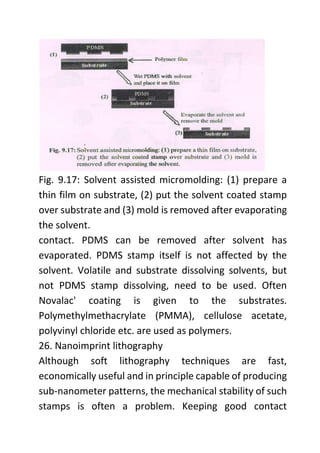

Mechanical lithography uses scanning probe microscopy tips to produce nanoscale patterns on surfaces. Tips can be used to scratch or move individual atoms or molecules, forming pits or lines as small as 30 nm in diameter. Dip pen lithography is a similar technique where an AFM tip "writes" molecular ink patterns in lines as thin as 15 nm. Other scanning probe lithography methods include thermo-mechanical lithography using heat from a laser to enable tip penetration, and electrical methods applying a voltage between tip and sample.