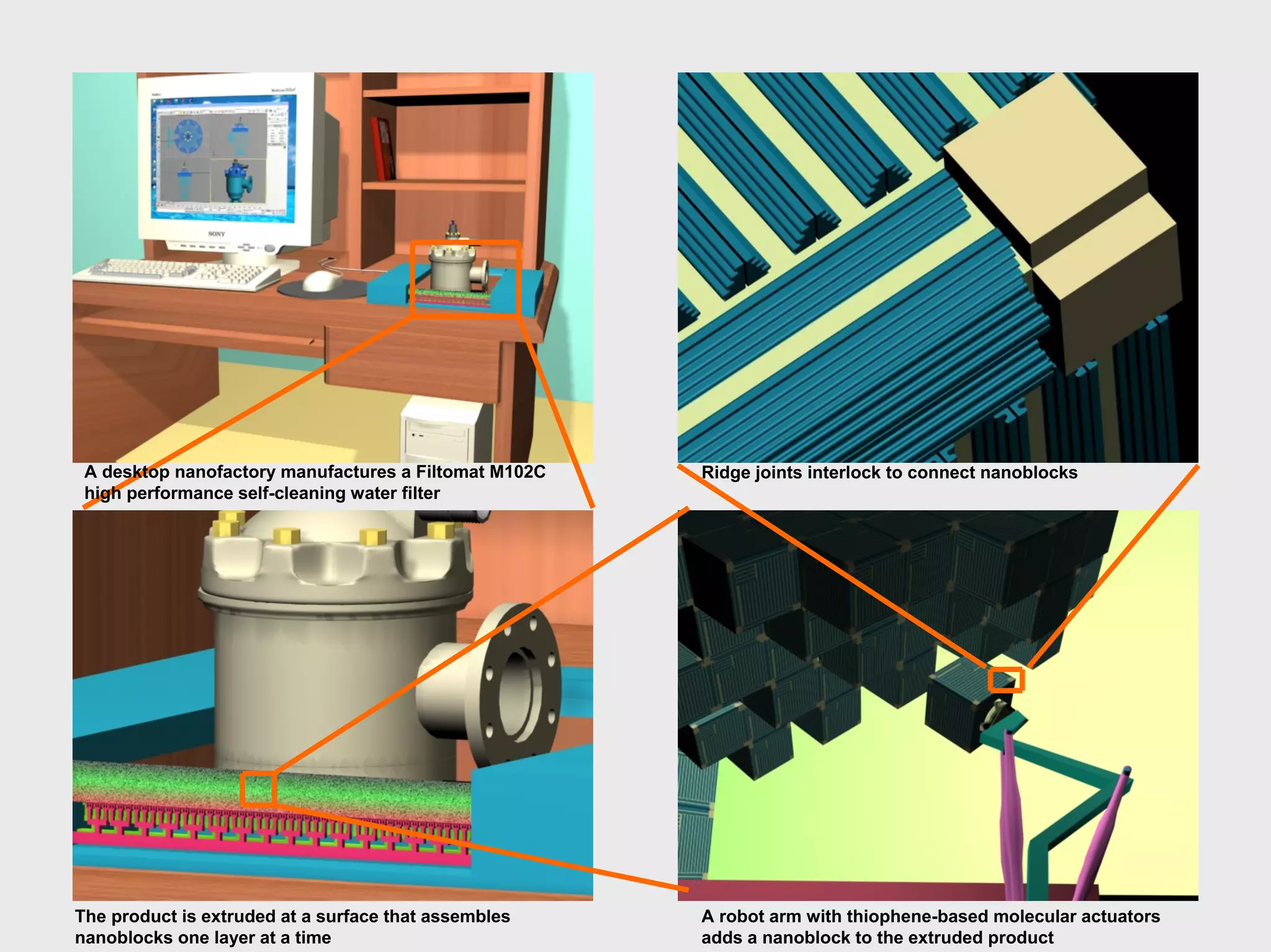

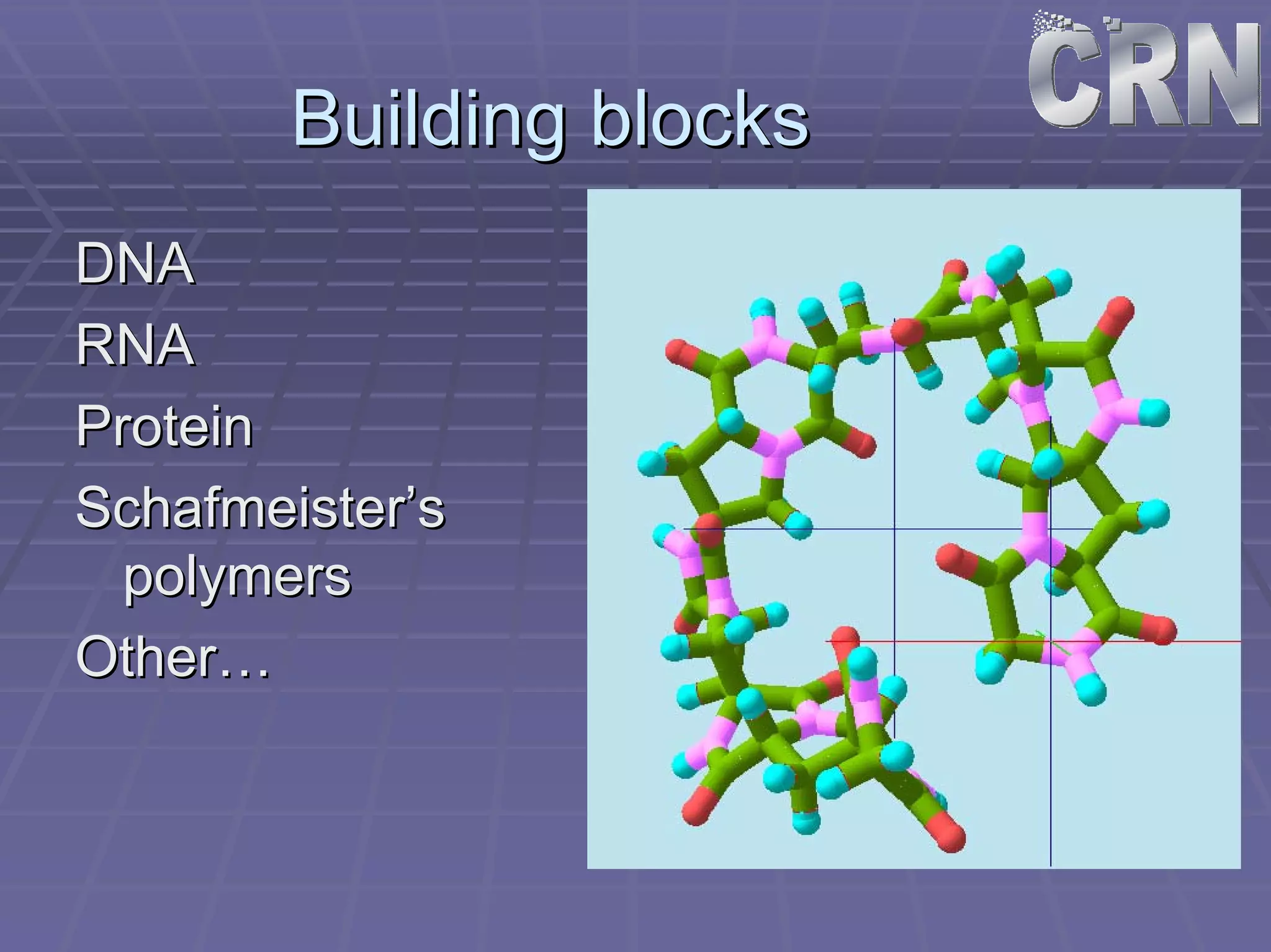

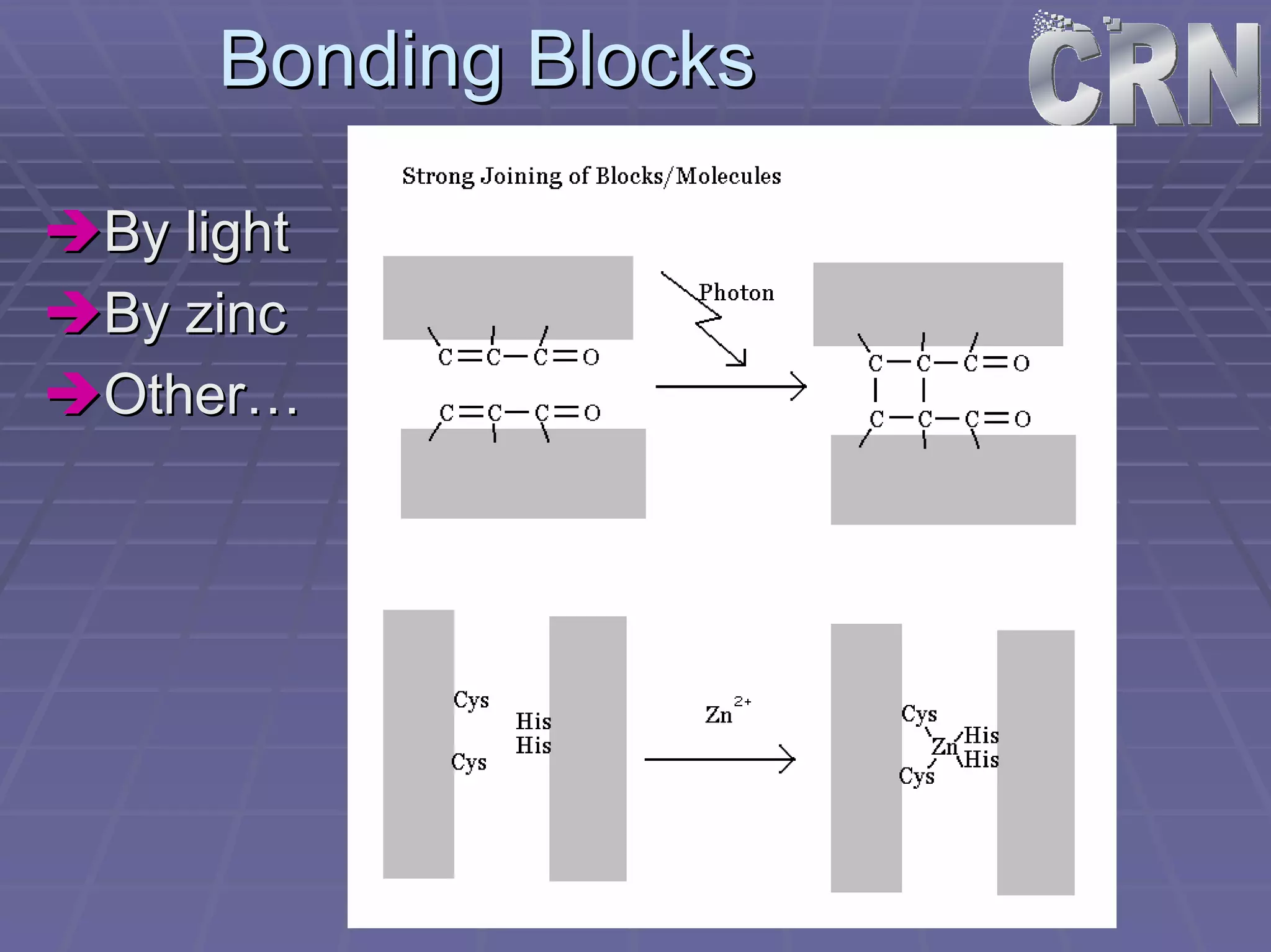

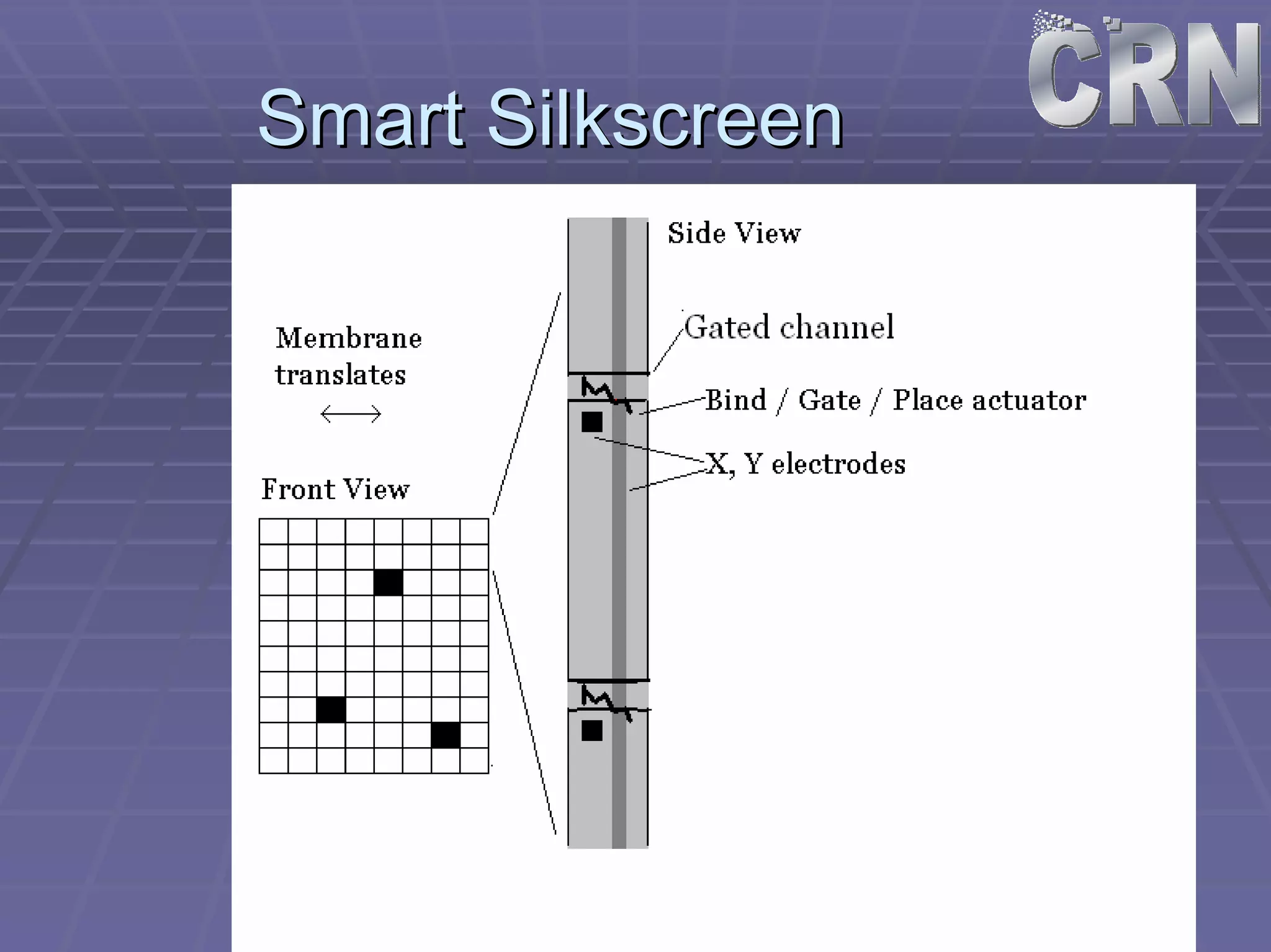

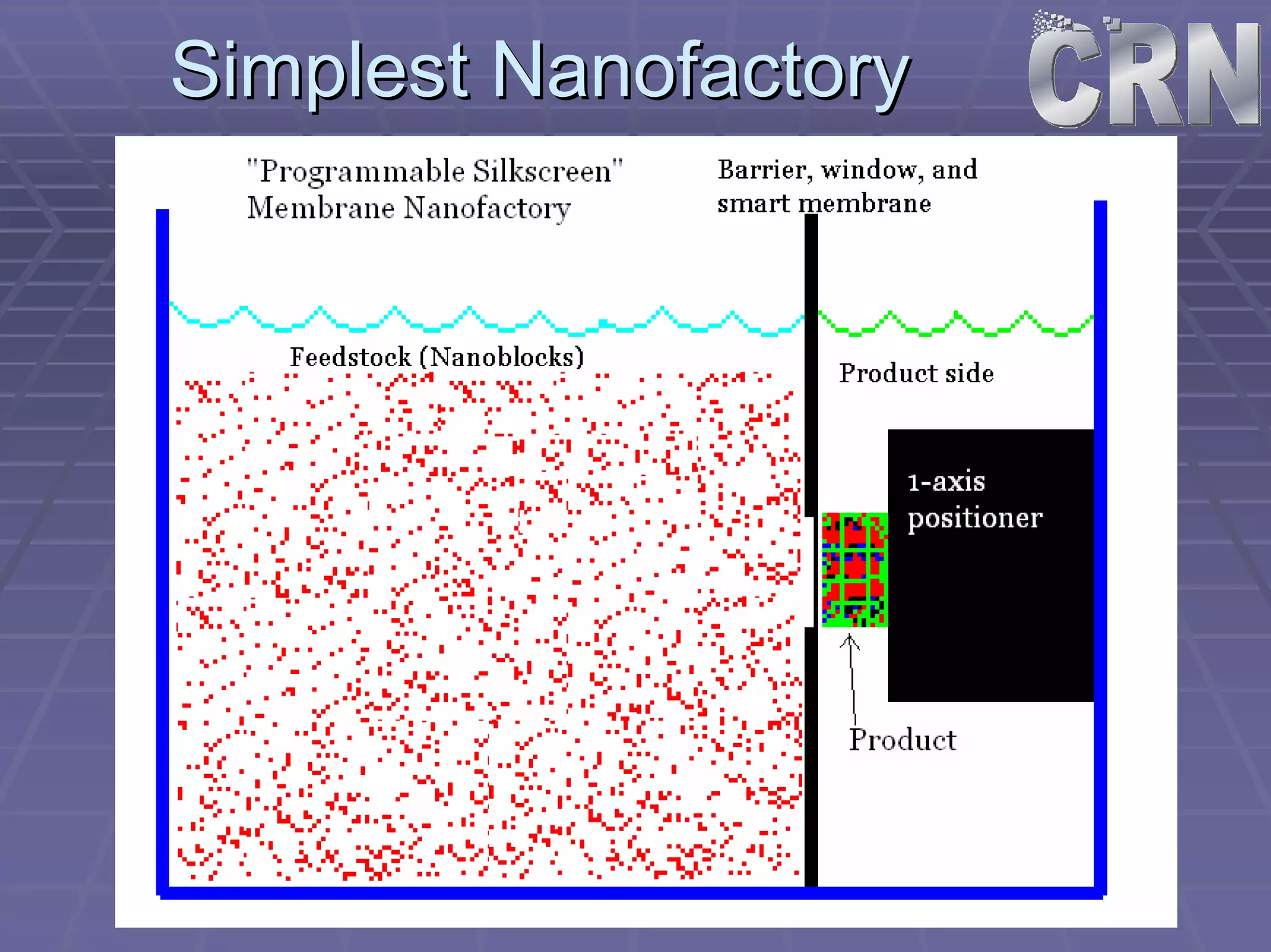

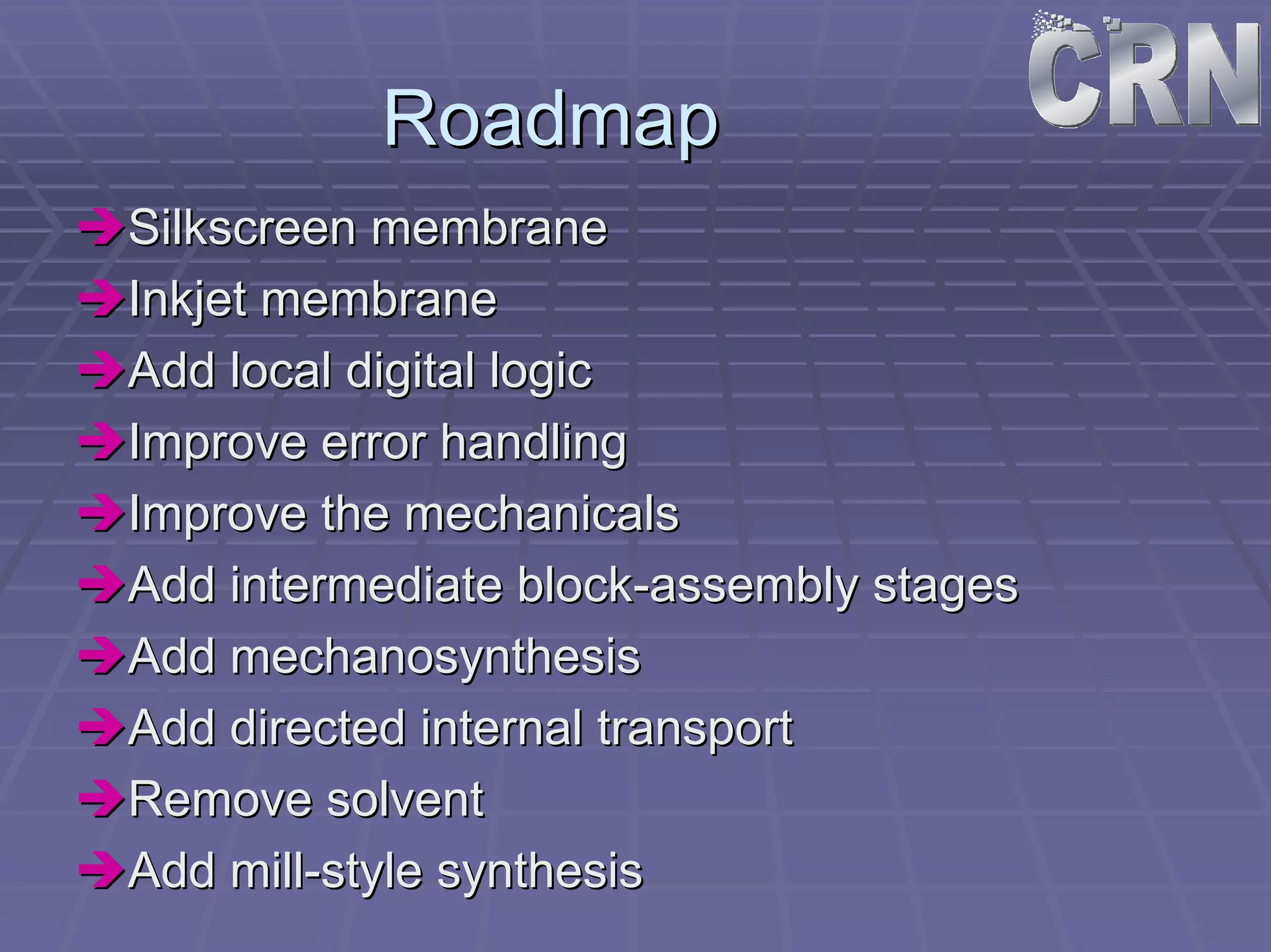

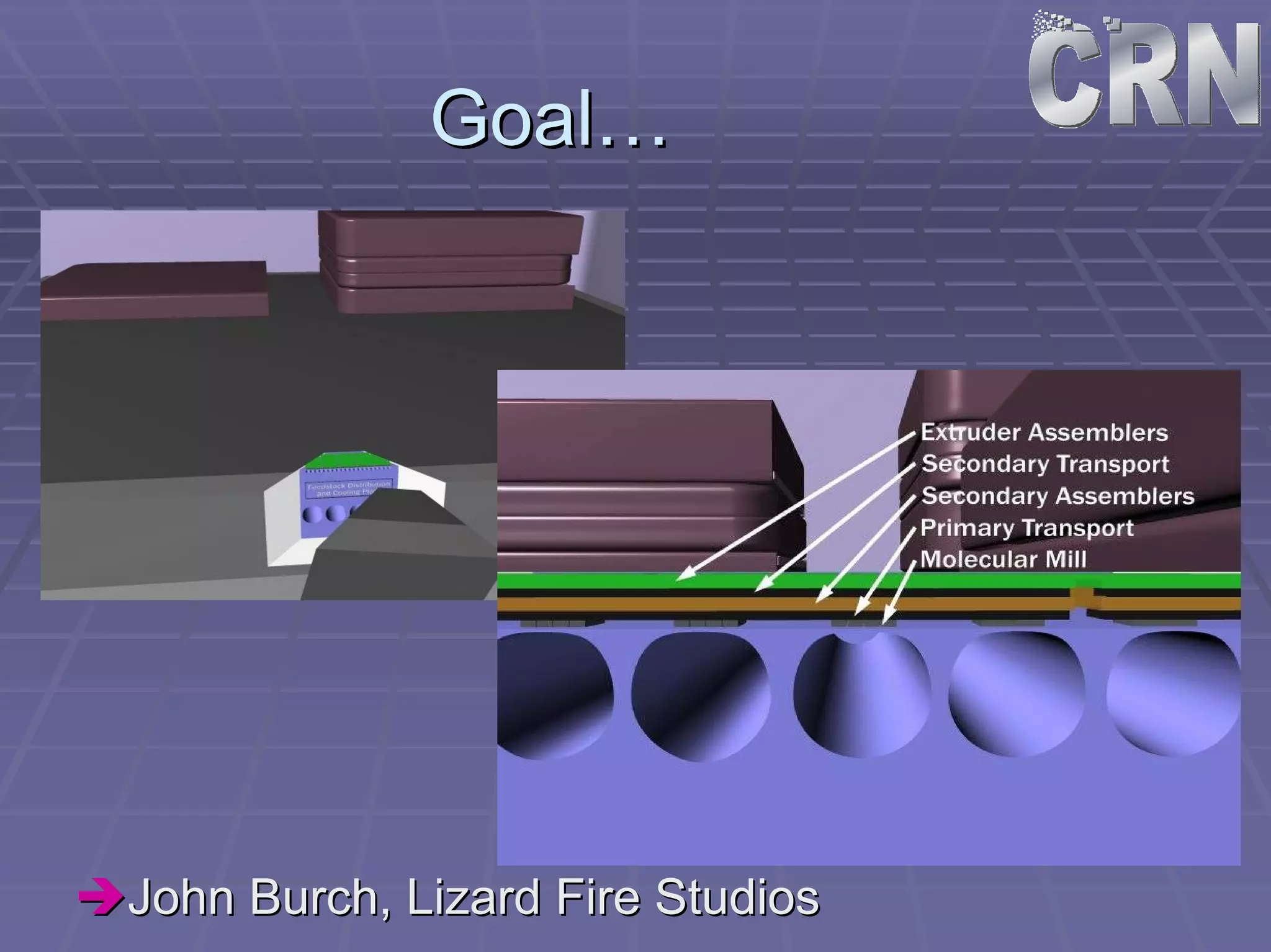

The document discusses the concept of primitive molecular manufacturing using nanoscale tools and techniques. It proposes building precise nanoscale structures through a digital engineering approach involving molecular fabrication, assembly operations, and information handling. The eventual goal is to develop large, high-performance manufacturing tools including a desktop nanofactory capable of producing its own mass in an hour. The presentation outlines some foundational concepts, existing capabilities, and a roadmap for further research.