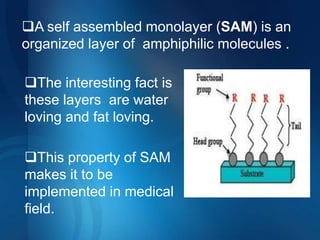

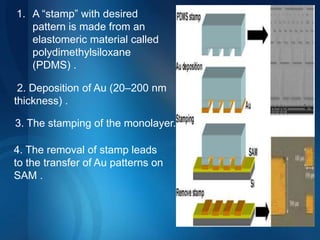

This document discusses self-assembled monolayers (SAMs) and their potential applications in nanoelectronics. SAMs are organized layers of amphiphilic molecules that spontaneously assemble on substrates like silicon. They have three parts - a head group that attaches to the substrate, an alkyl chain, and a surface group. SAMs can be characterized and patterned using lithography techniques. Electronic conduction in SAMs occurs through tunneling between energy levels. Potential SAM devices include molecular rectifiers and transistors, which could enable smaller, more efficient electronics. Challenges include the difficulty of nano-scale lithography manufacturing.