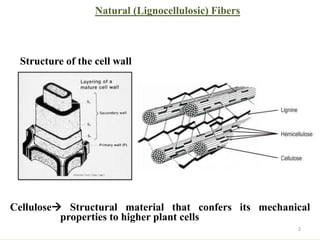

This document discusses nanocellulose, including its production from various raw materials, properties, and potential applications. Nanocellulose can be produced through various processes like mechanical and chemical treatments. It has properties like high strength, thermal stability, and biodegradability. Potential applications of nanocellulose mentioned include use in electronics, sensors, construction materials, filtration, medical implants, packaging, composites, hydrogels, paints and coatings, paper and more. Characterization of nanocellulose produced from corn husk showed high crystallinity, thermal stability, and particle sizes in the nanometer range. Further stability studies are required before utilizing it in various applications.

![Nano Cellulose (NC)

Details of the z-shaped interaction chamber of the

microfluidizer (Microfluidics Inc., USA)

Ultra-fine friction grinder

[http://www.masuko.com/English/product/

Masscolloder.html]

12](https://image.slidesharecdn.com/nanocelluloseroshni-161018044416/85/Nano-cellulose-roshni-12-320.jpg)