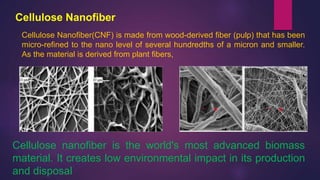

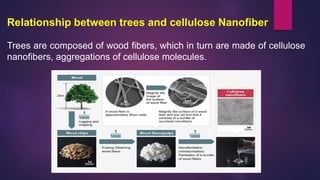

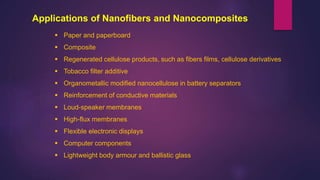

Cellulose nanofiber is made from wood fibers that have been micro-refined to the nano scale and are several hundredths of a micron in size. It is the world's most advanced biomass material due to its light weight, strength, and low environmental impact. Cellulose nanofiber has properties including high strength, stiffness, barrier properties, and renewability that make it suitable for a wide range of applications like paper products, composites, and electronics.