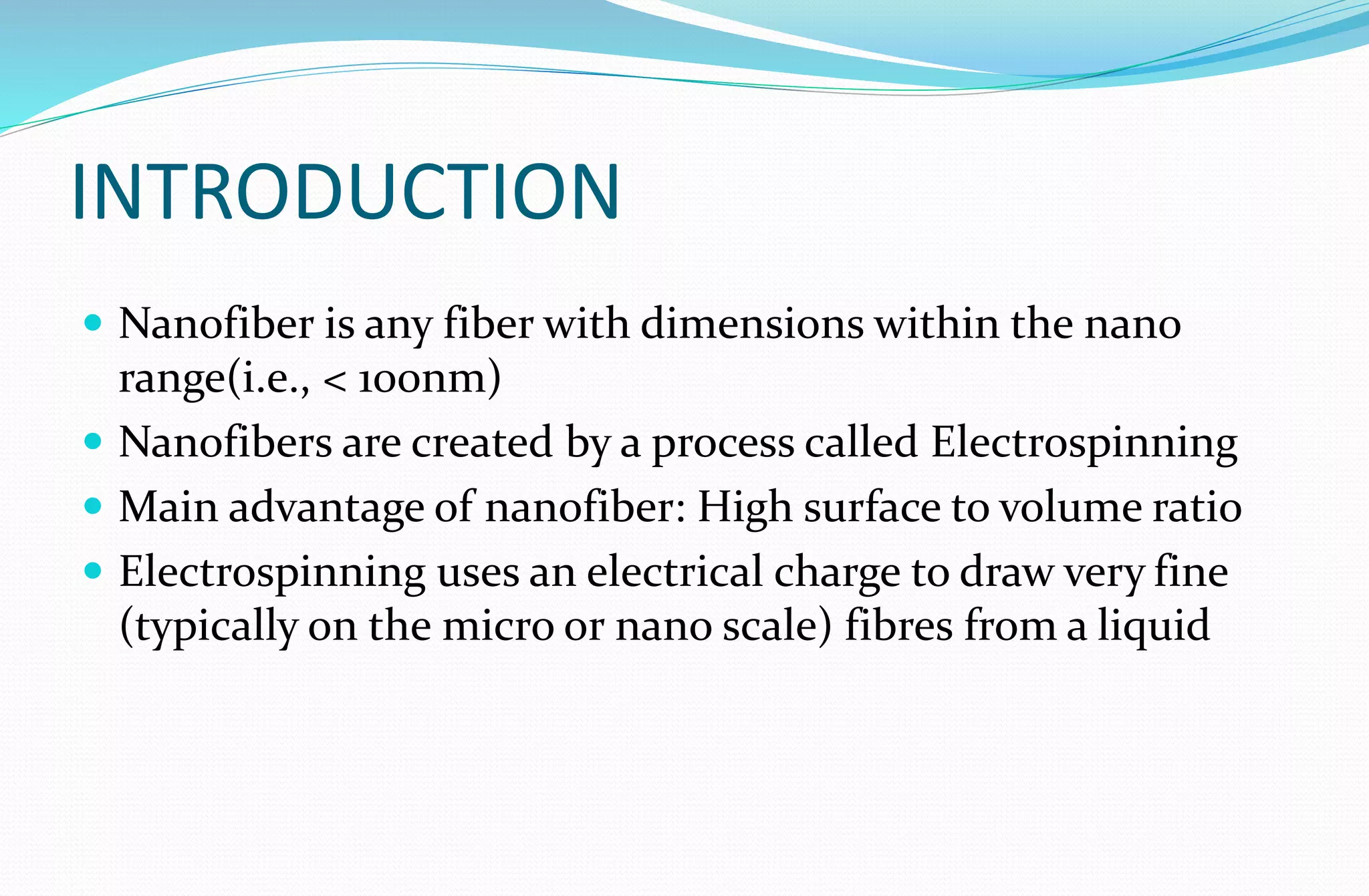

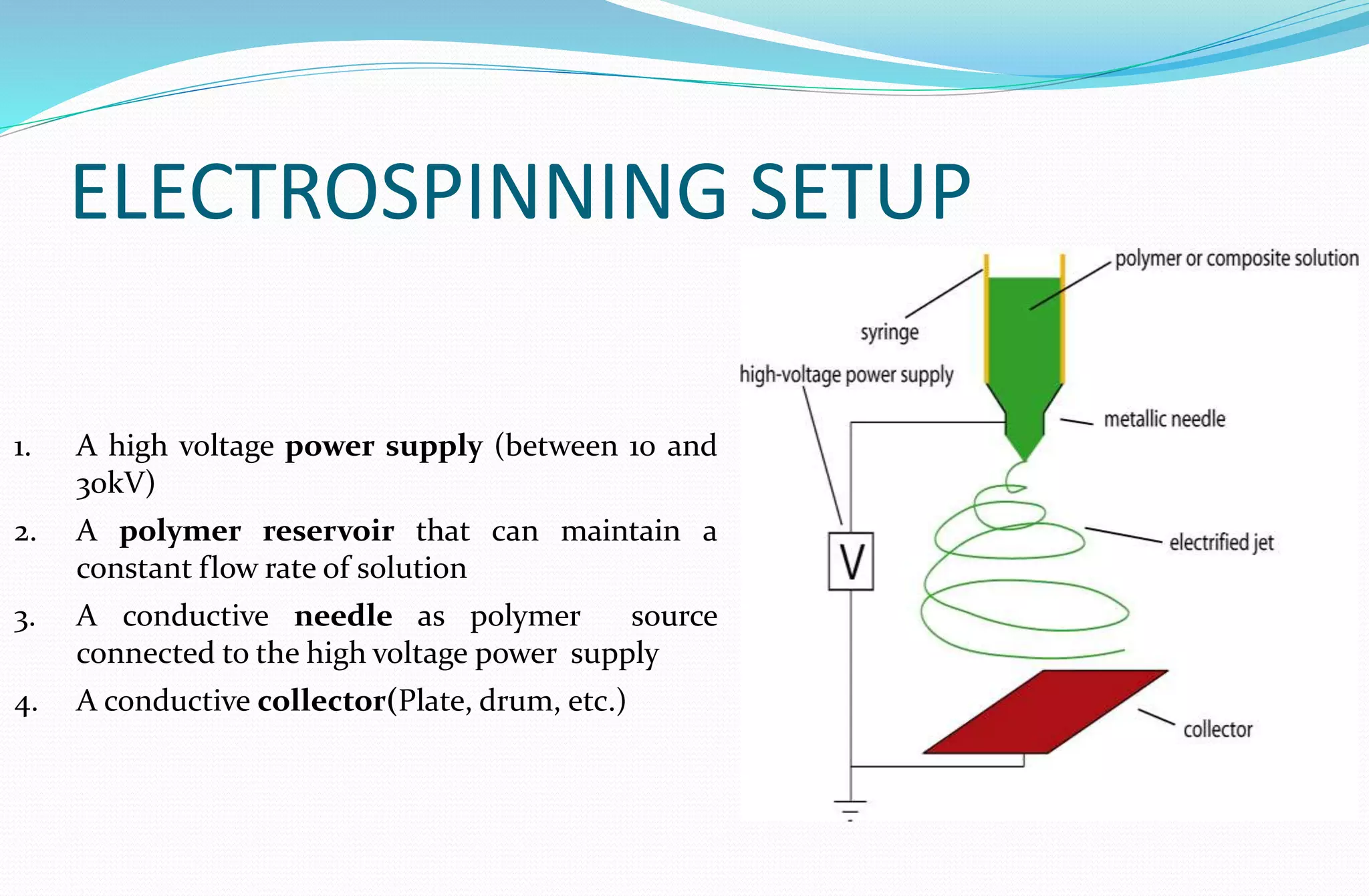

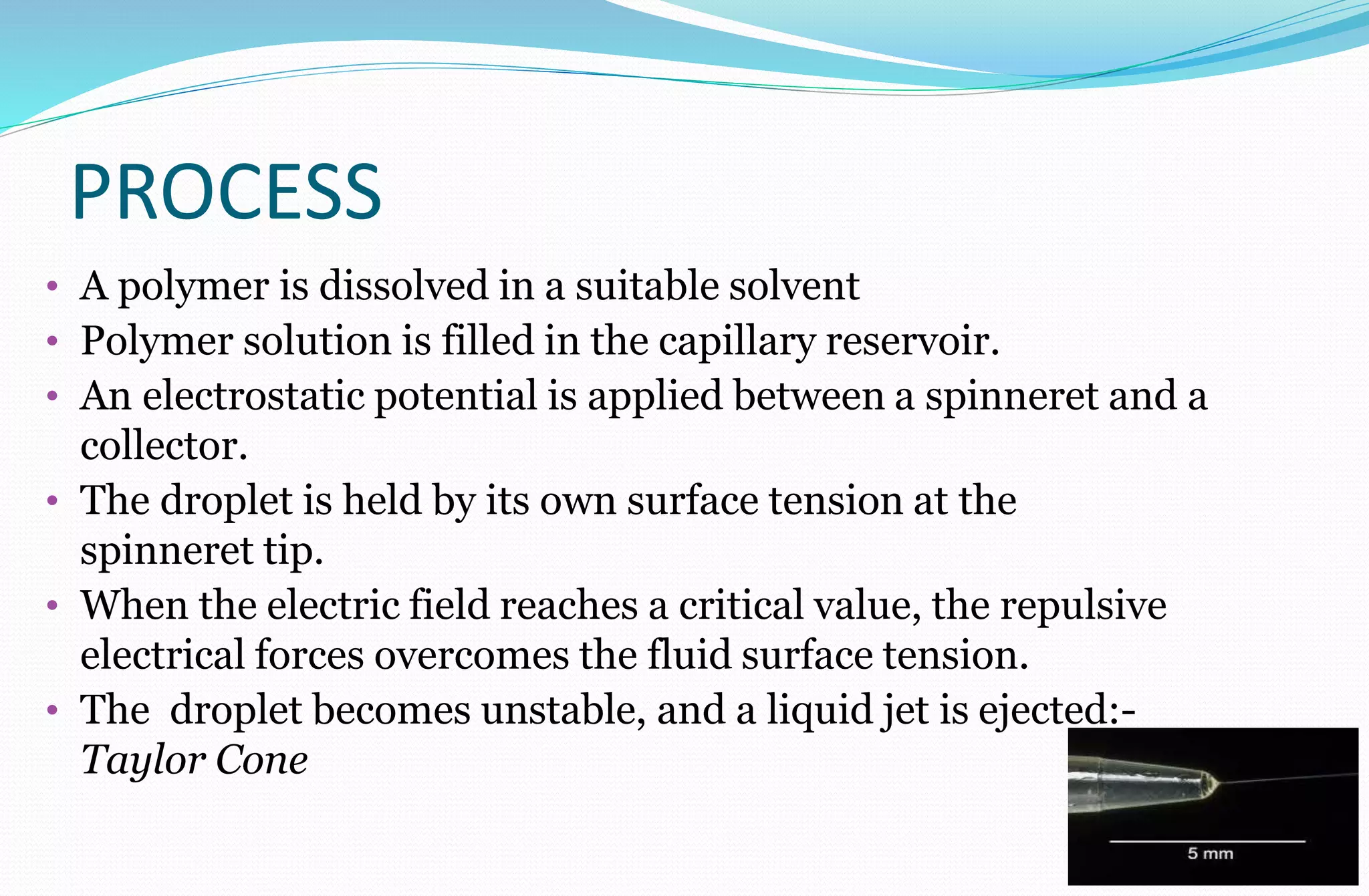

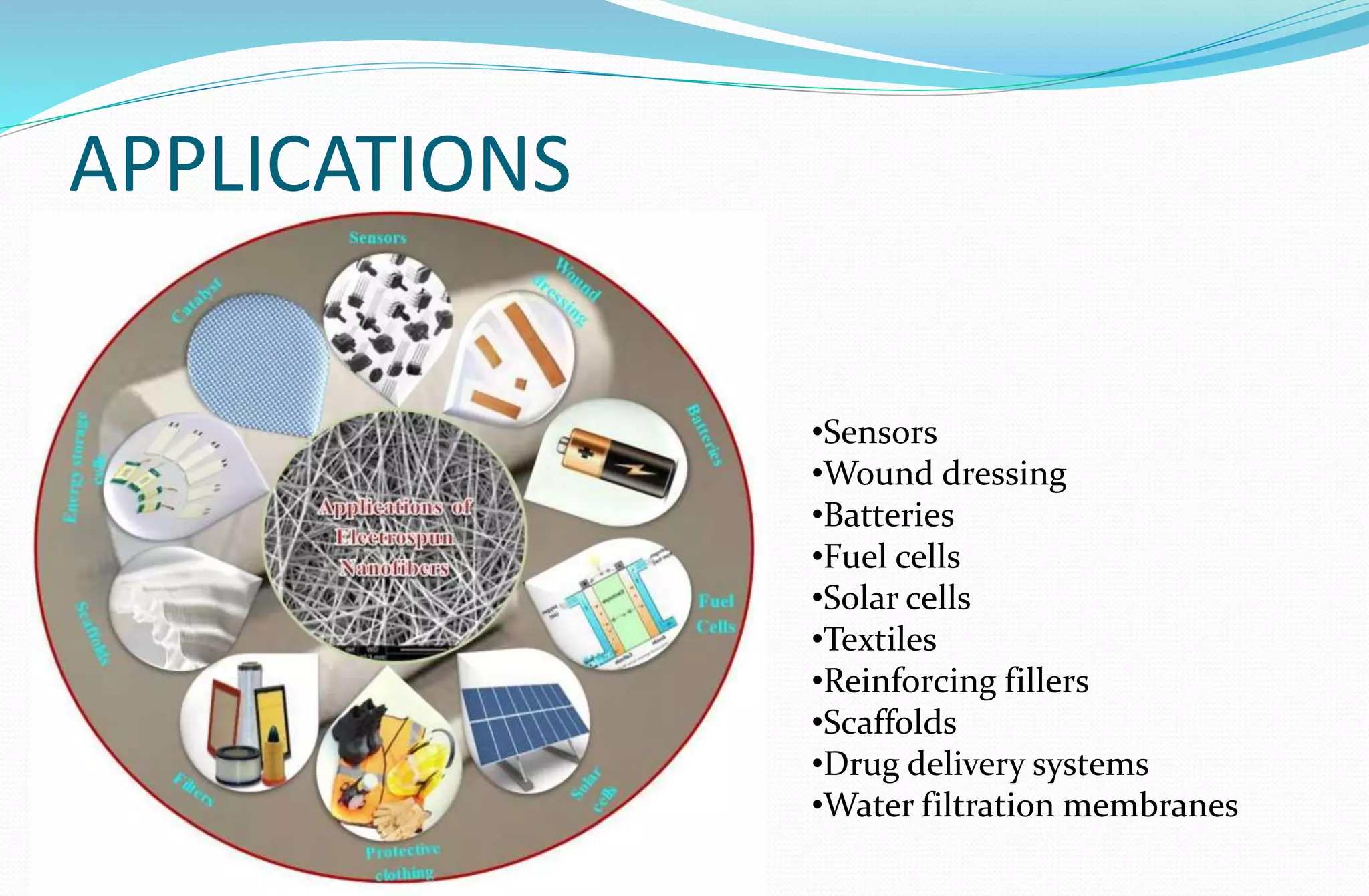

The document details the electrospinning process used to create nanofibers, which are fibers less than 100nm in diameter. It discusses the principles, parameters, advantages, characterizations, and applications of electrospun nanofibers, including their use in sensors, drug delivery systems, and tissue engineering. Key advantages of nanofibers include their high surface area to volume ratio, porosity, and customizable properties.