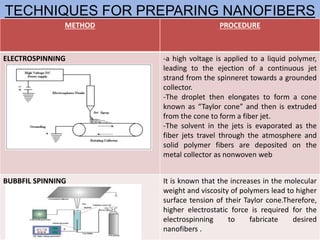

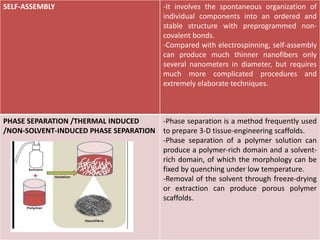

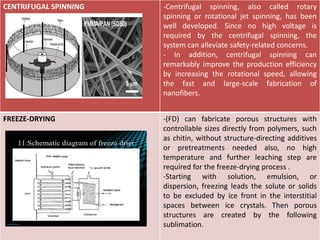

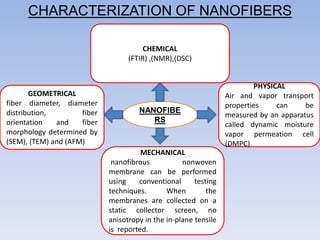

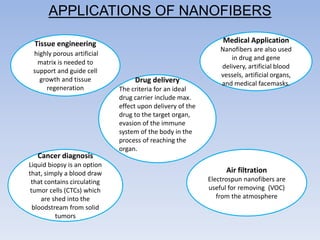

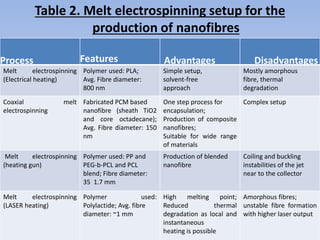

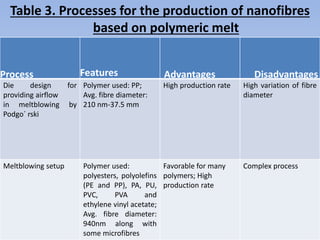

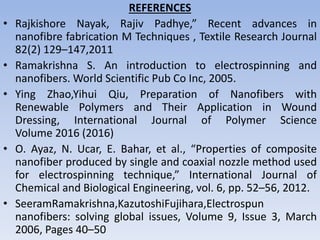

The document discusses the definition, properties, and applications of nanofibers, which are fibers with diameters less than 50-500 nanometers. It details various techniques for preparing nanofibers such as electrospinning, self-assembly, and phase separation, along with their advantages and disadvantages. Additionally, it highlights the use of nanofibers in drug delivery, tissue engineering, cancer diagnosis, and air filtration.