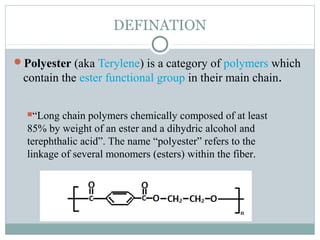

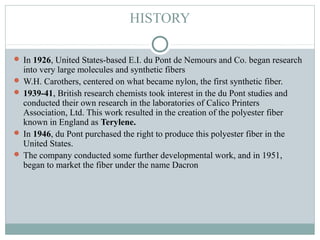

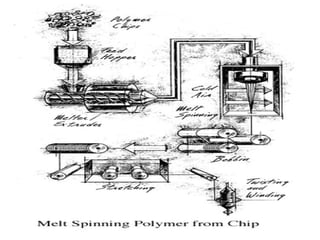

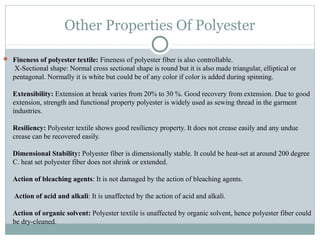

Polyester is a synthetic polymer made from petroleum-based raw materials. It was first developed in the 1940s and commercialized in the 1950s under the name Dacron. The document provides details on the history, manufacturing process, properties, uses, care instructions, and future developments of polyester fiber. It summarizes the key characteristics that make polyester durable, wrinkle and stain resistant, and easy to care for in clothing and other applications.