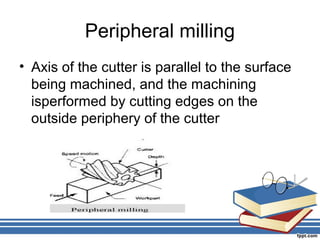

Milling machines were first invented in 1798 to mass produce interchangeable parts. A milling machine removes material from a workpiece using a rotating cutter. It contains sensors, actuators, mechanical elements like cutters and teeth, and basic components including a worktable, head, knee, and saddle. There are two main types - vertical and horizontal milling machines. Milling can be done peripherally with the cutter parallel to the surface, or by face milling with the cutter perpendicular to cut both ends and sides.