This document provides an overview of various machining operations presented in a classroom lecture, including:

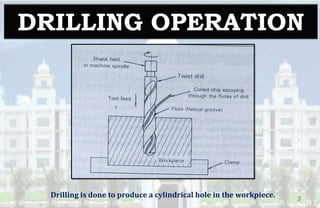

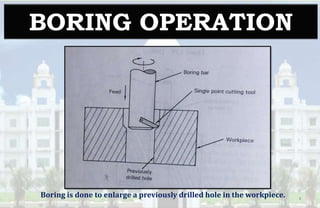

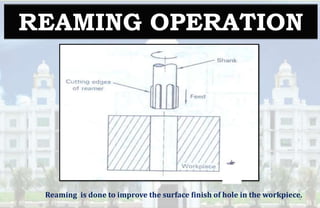

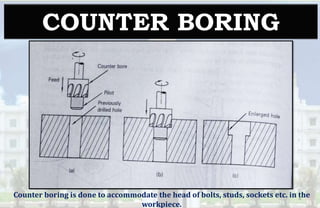

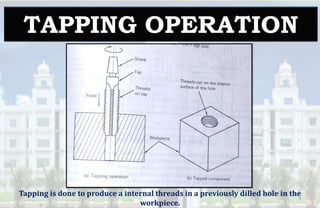

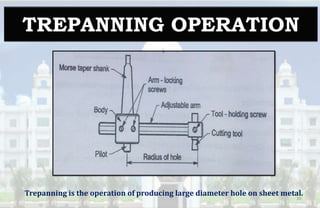

1. Drilling, boring, reaming, counterboring, countersinking, spot facing, and tapping operations for producing holes in workpieces.

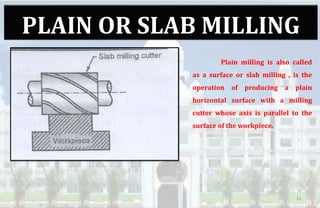

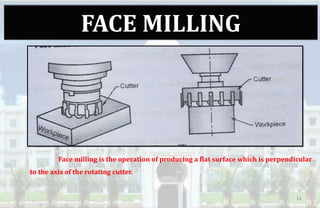

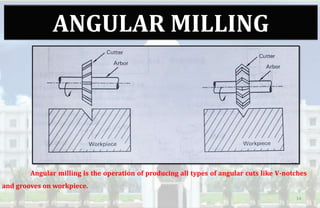

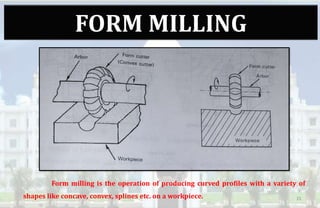

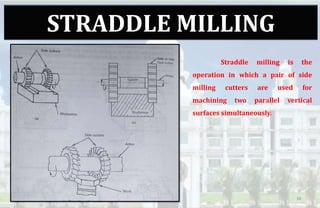

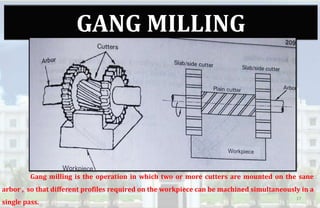

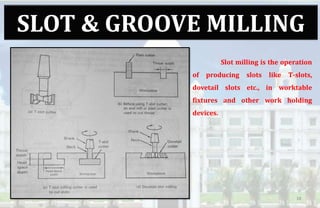

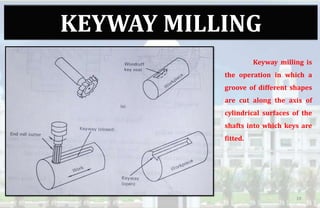

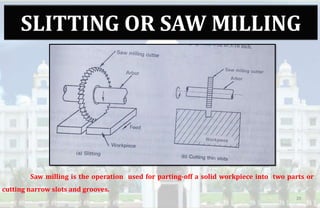

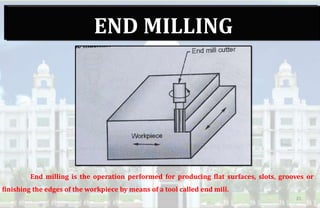

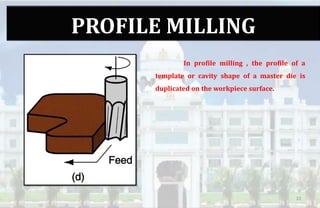

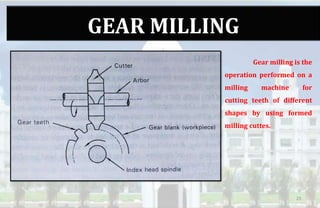

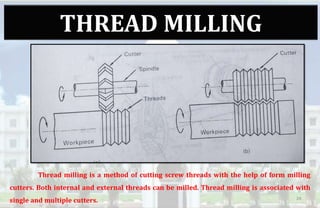

2. Milling operations such as plain milling, face milling, angular milling, form milling, straddle milling, gang milling, slot and groove milling, keyway milling, slitting, end milling, profile milling, gear milling, and thread milling. Definitions and purposes are given for each operation.

3. The document appears to be from a Mechanical Engineering class focusing on machining