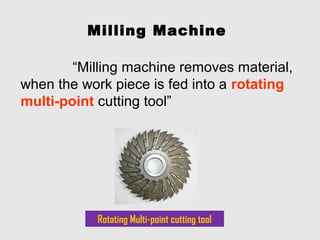

The document provides information on milling machines and gear generation. It discusses the different types of milling machines, milling processes like up and down milling, and milling cutters. The various milling operations like plain milling, face milling and gear cutting are explained. Indexing is described as the process of dividing the workpiece into equal parts and different indexing methods like simple indexing are covered. Gear types, gear forming, and mechanisms used for indexing like worm and worm gear are also summarized.