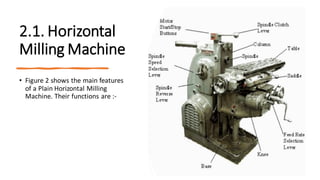

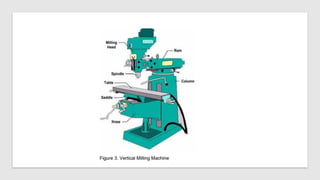

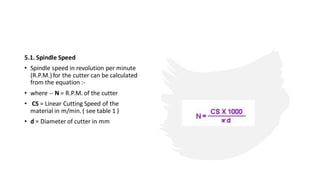

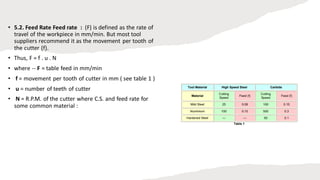

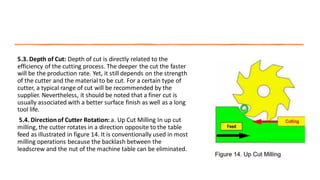

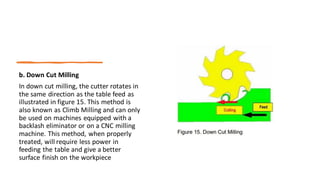

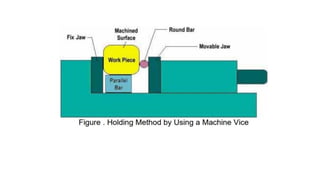

This document provides an overview of milling machines and milling processes. It describes the two main types of milling machines - horizontal and vertical milling machines. It outlines common cutting tools and industrial applications of milling. The key milling processes of spindle speed, feed rate, depth of cut, and cutter rotation direction are explained. Typical milling operations such as plain milling, end milling and gang milling are defined. The document also covers workholding methods and the importance of vice alignment and safety practices.