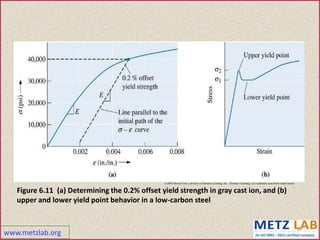

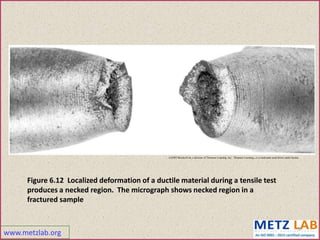

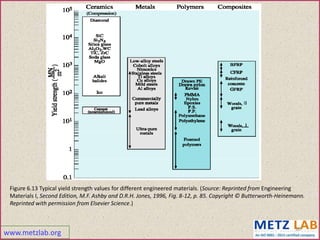

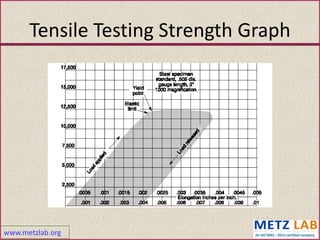

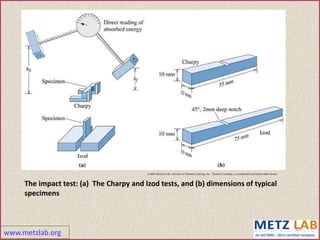

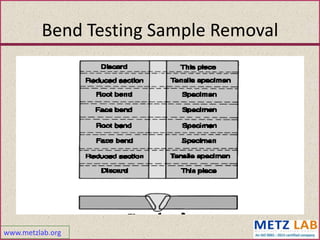

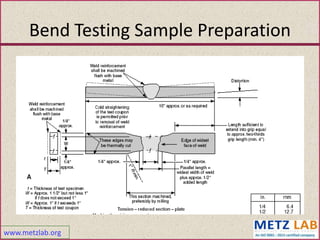

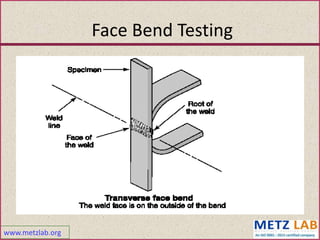

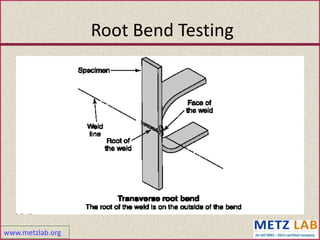

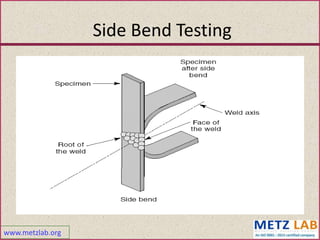

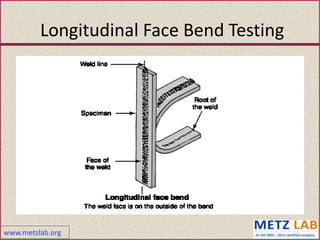

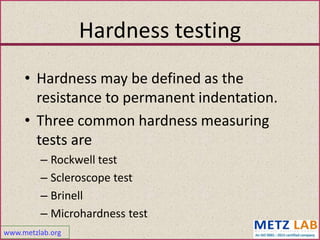

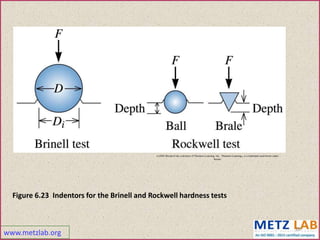

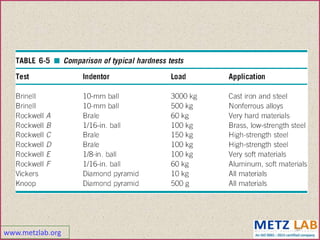

The document provides an overview of metallurgical testing methods including destructive testing, mechanical testing, chemical analysis, and metallography. It details specific testing techniques such as tensile, impact, bend, and hardness tests, outlining their objectives and methods. Additionally, it discusses the importance of these tests in assessing material properties and microstructure.