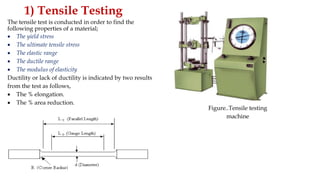

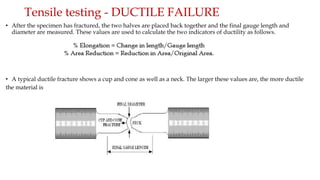

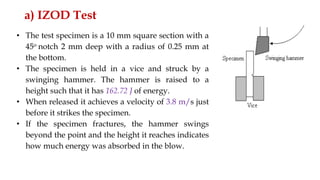

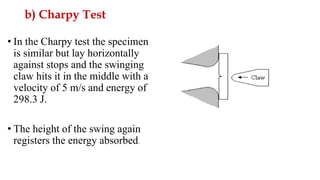

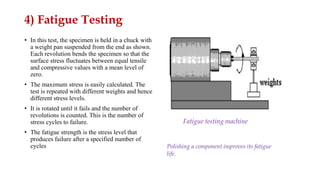

This document discusses various material testing methods, including destructive and non-destructive tests. It describes tensile testing to determine properties like yield strength and ductility. Other tests covered include impact testing for toughness, hardness testing using Brinell and Vickers methods, fatigue testing to determine cycles to failure, and creep testing to examine material extension over time under stress. The effects of temperature on material properties are also discussed.