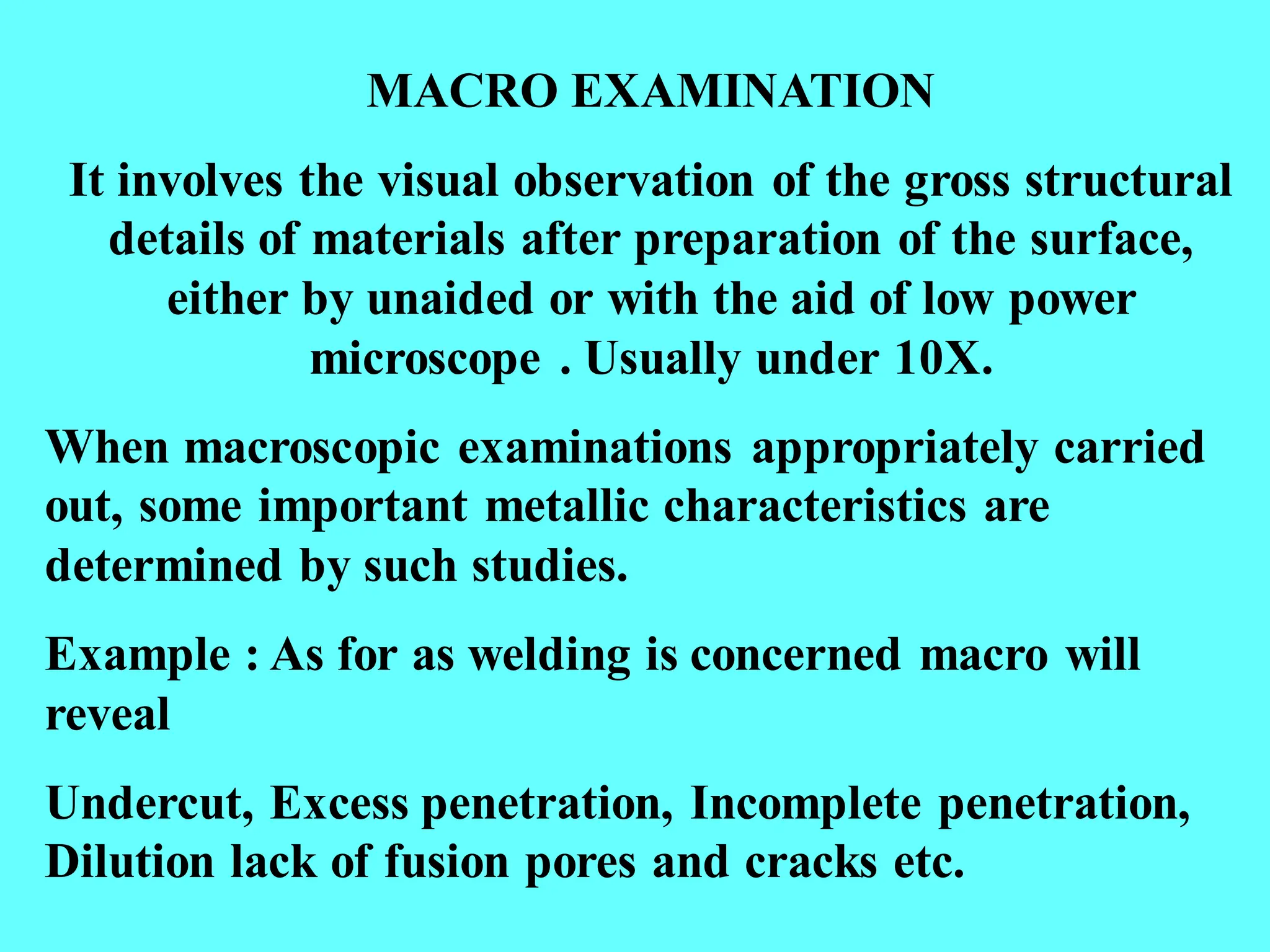

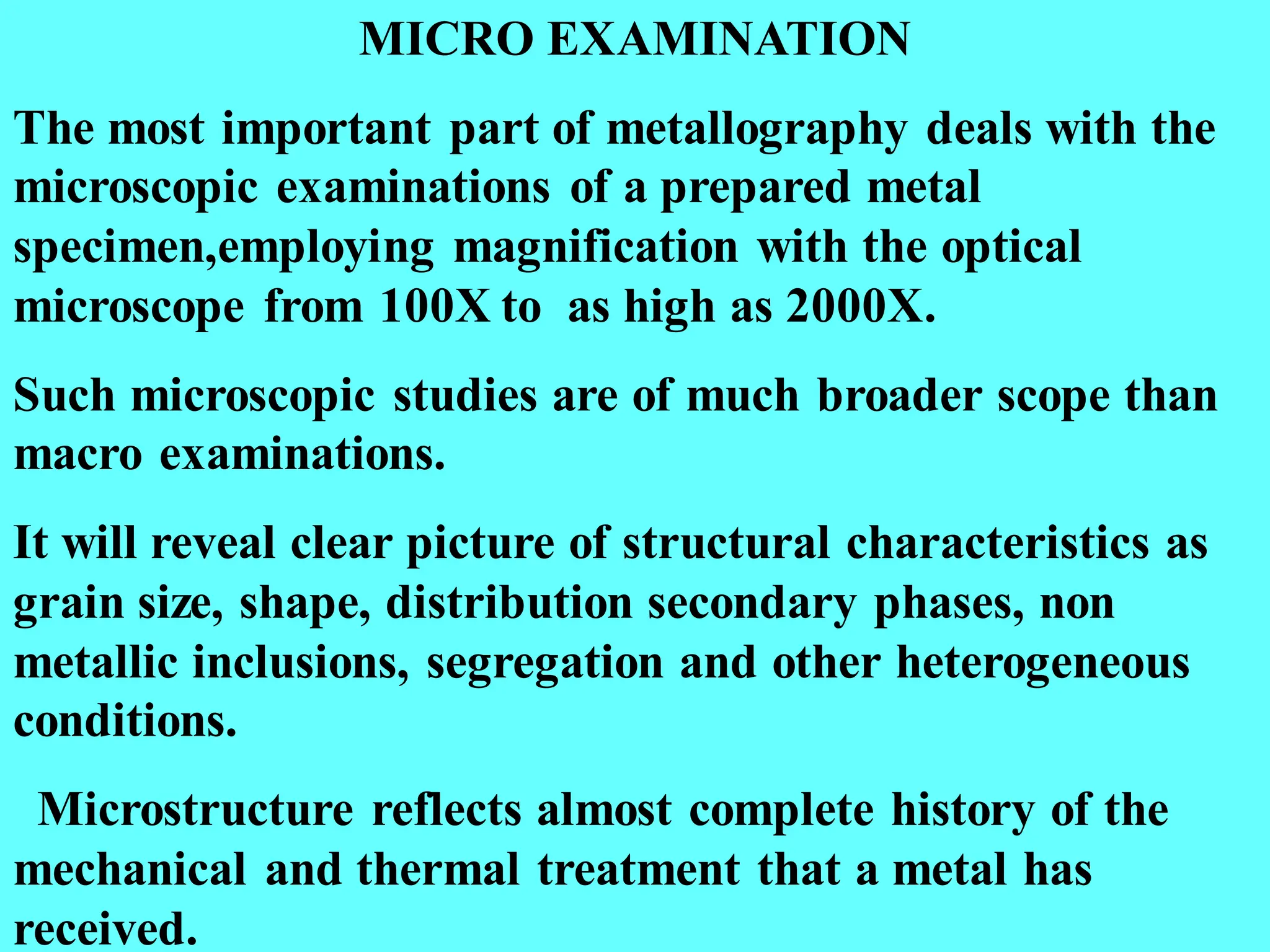

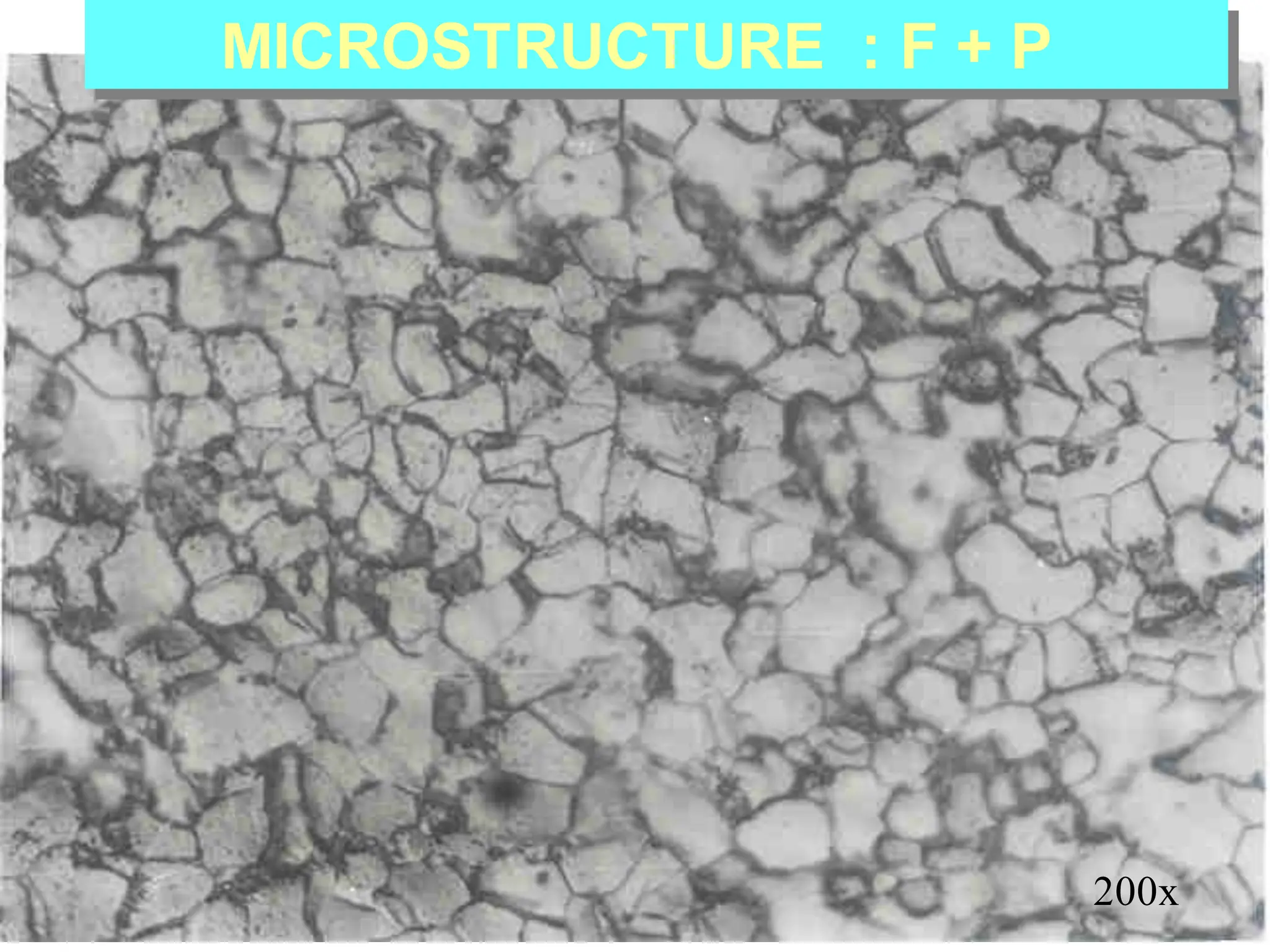

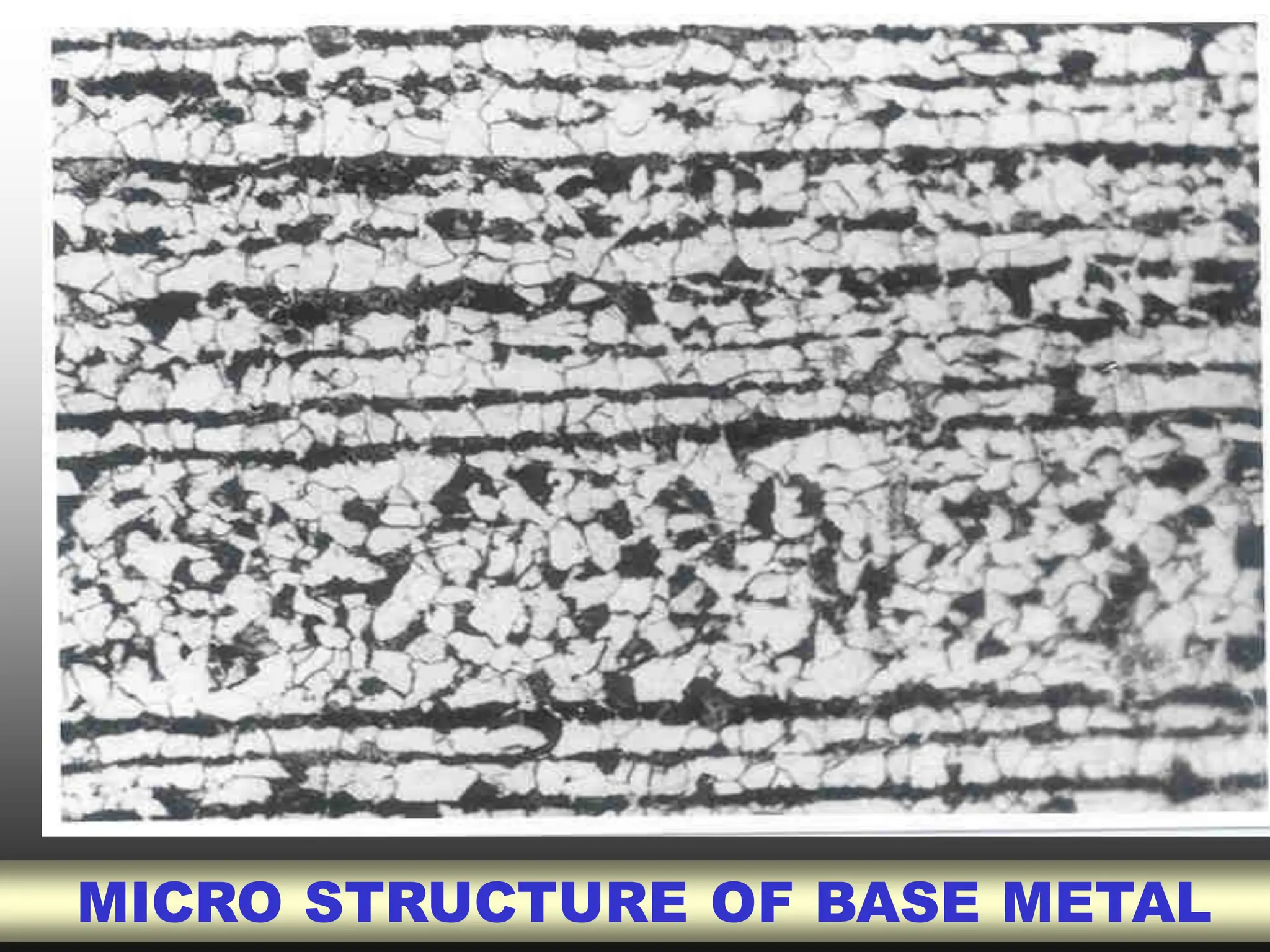

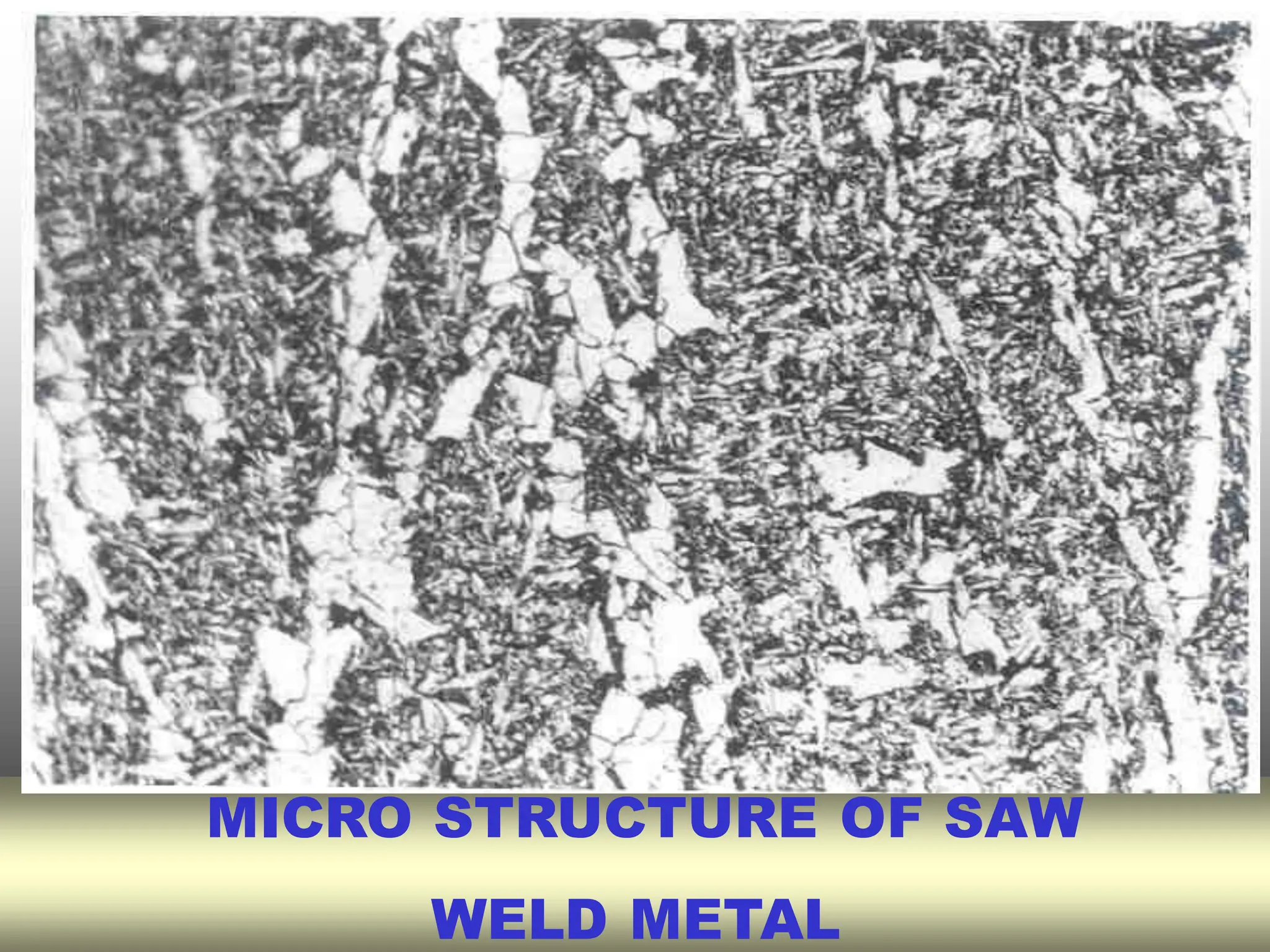

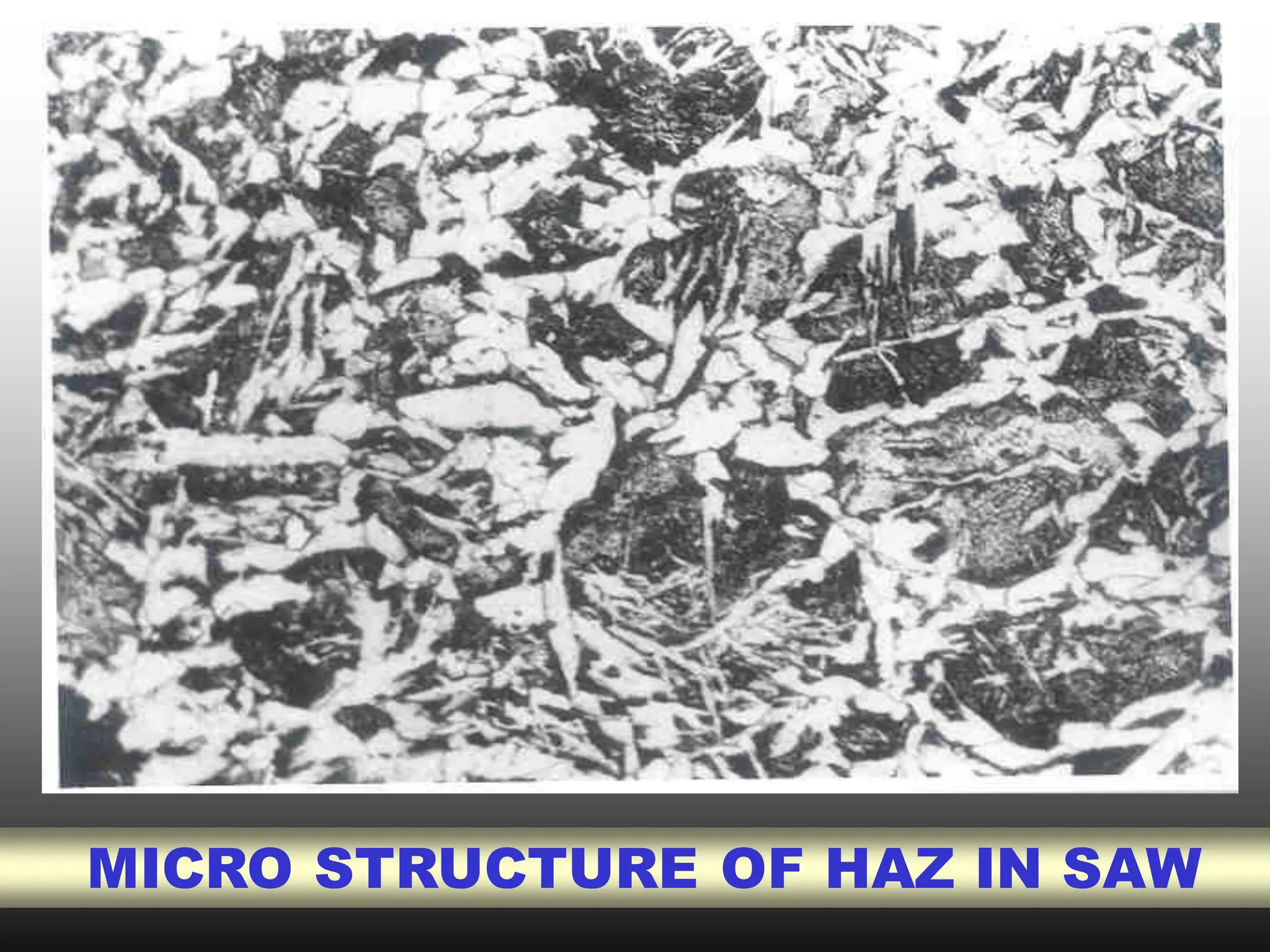

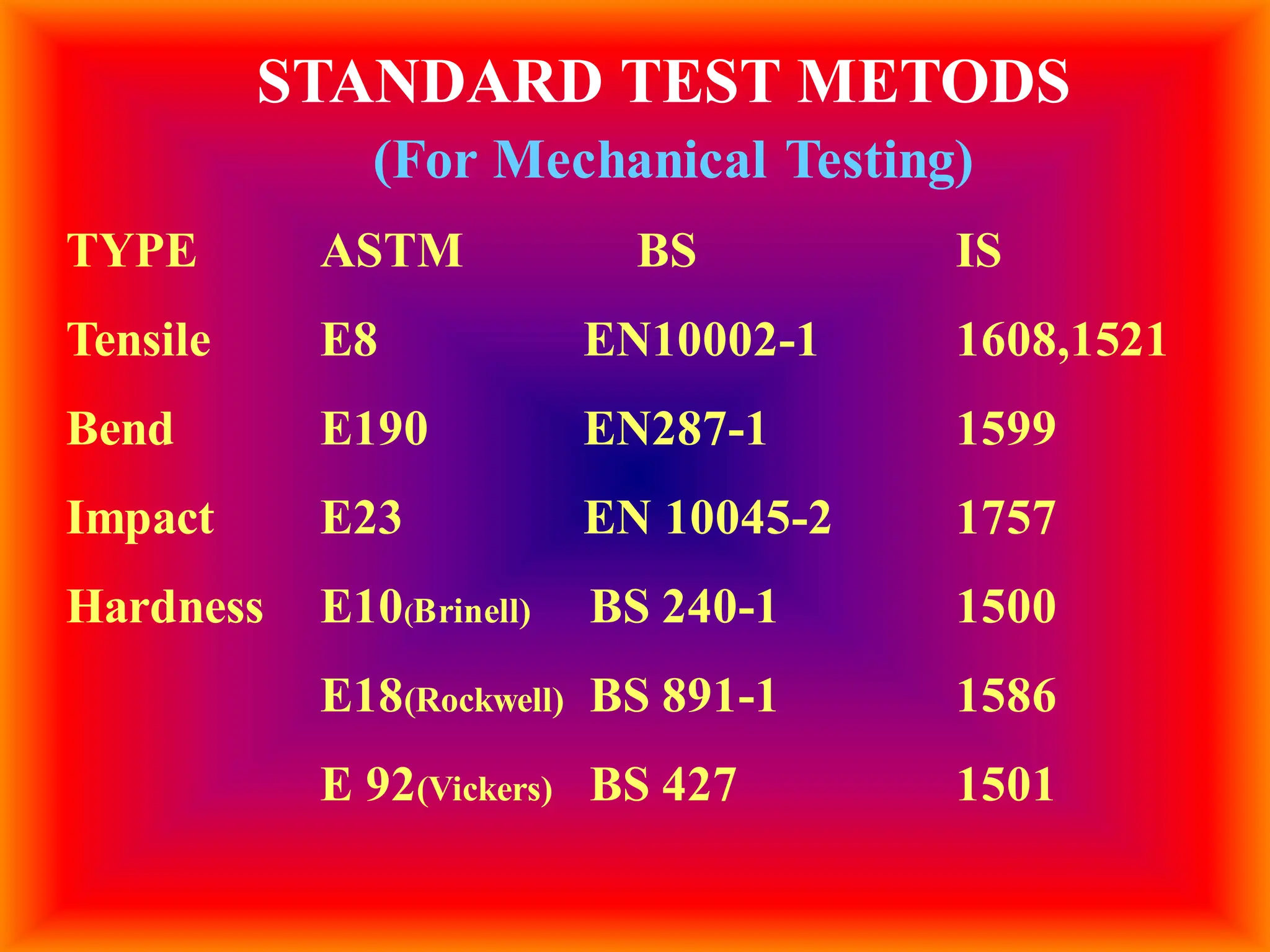

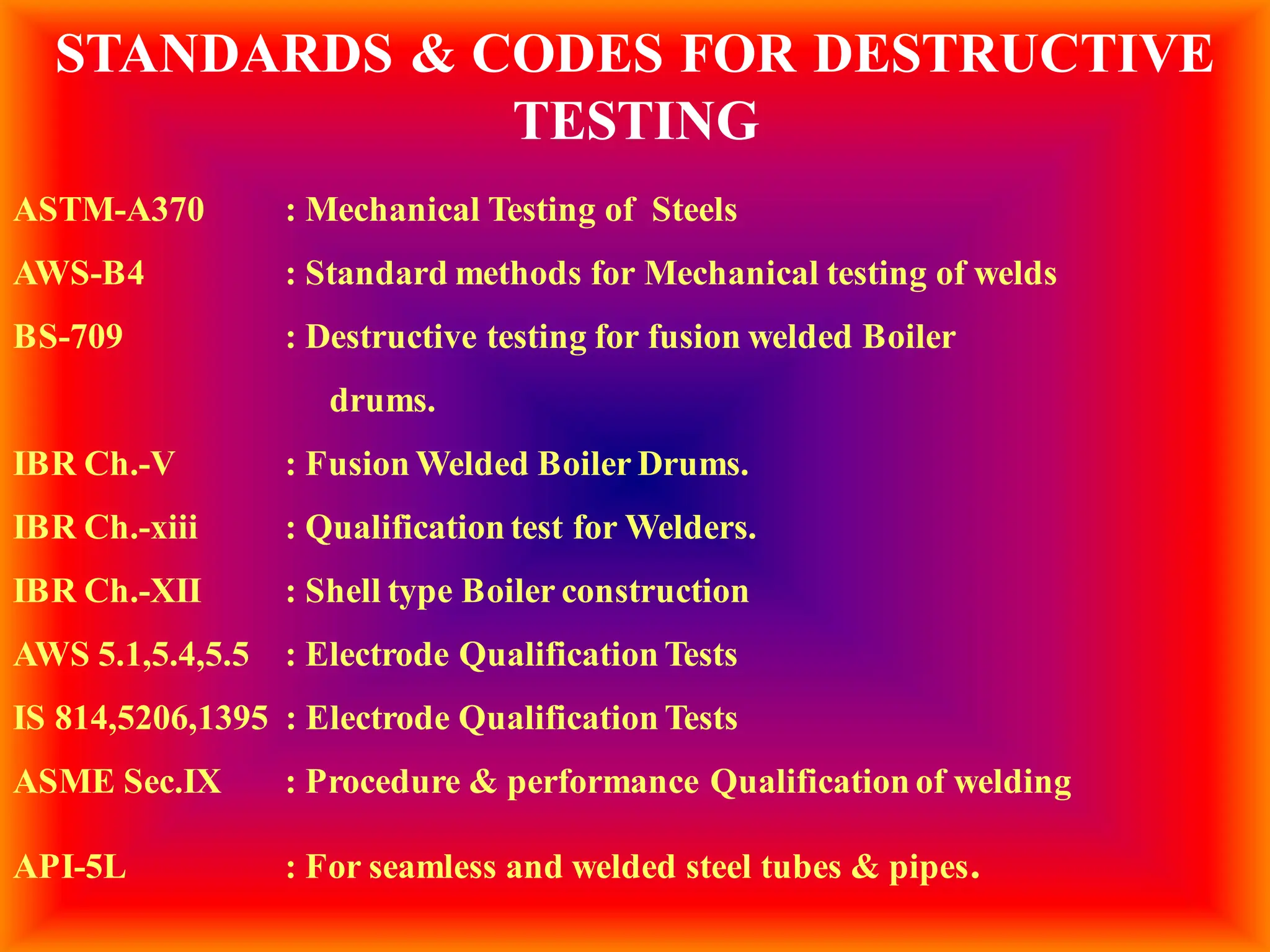

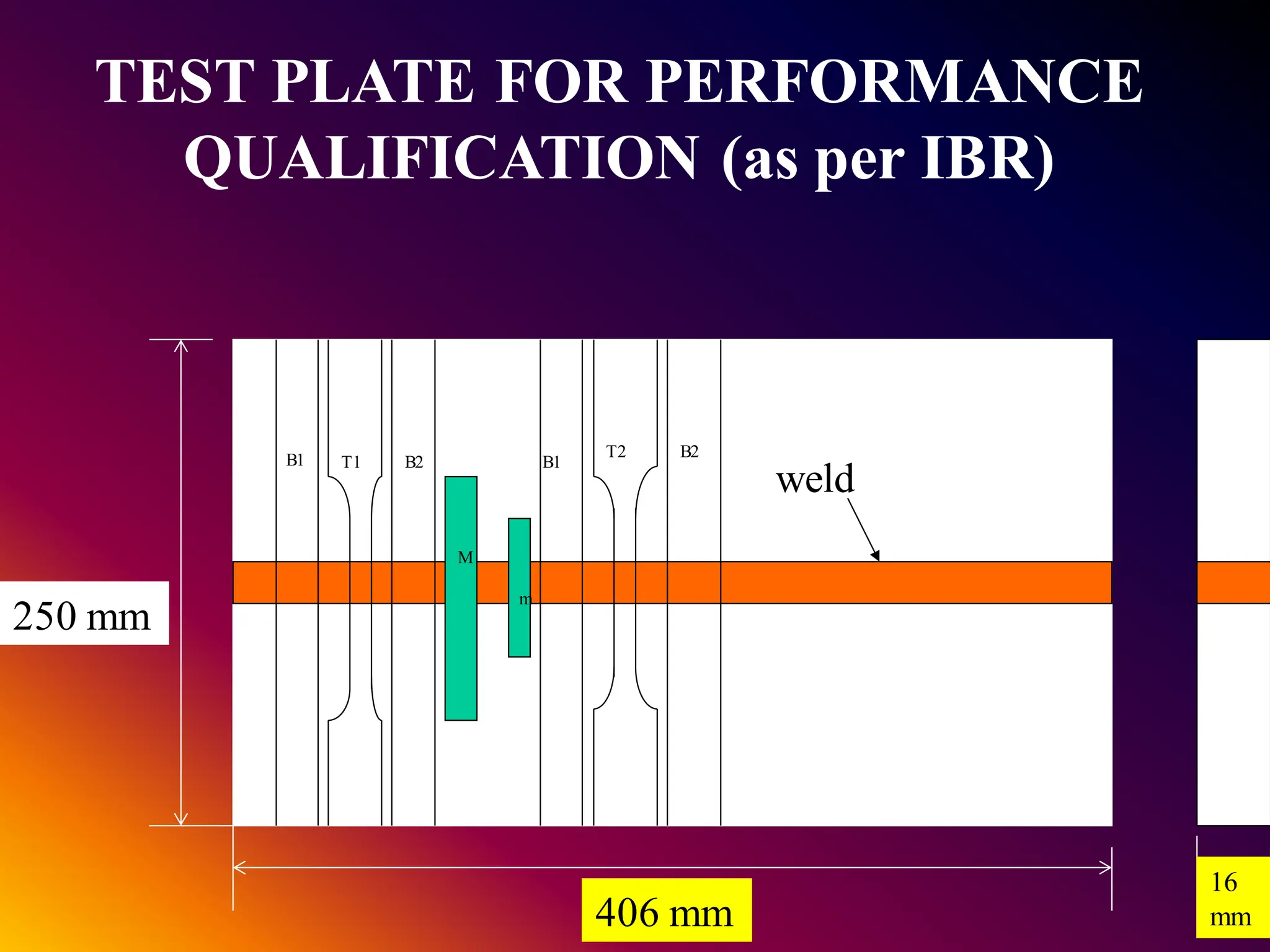

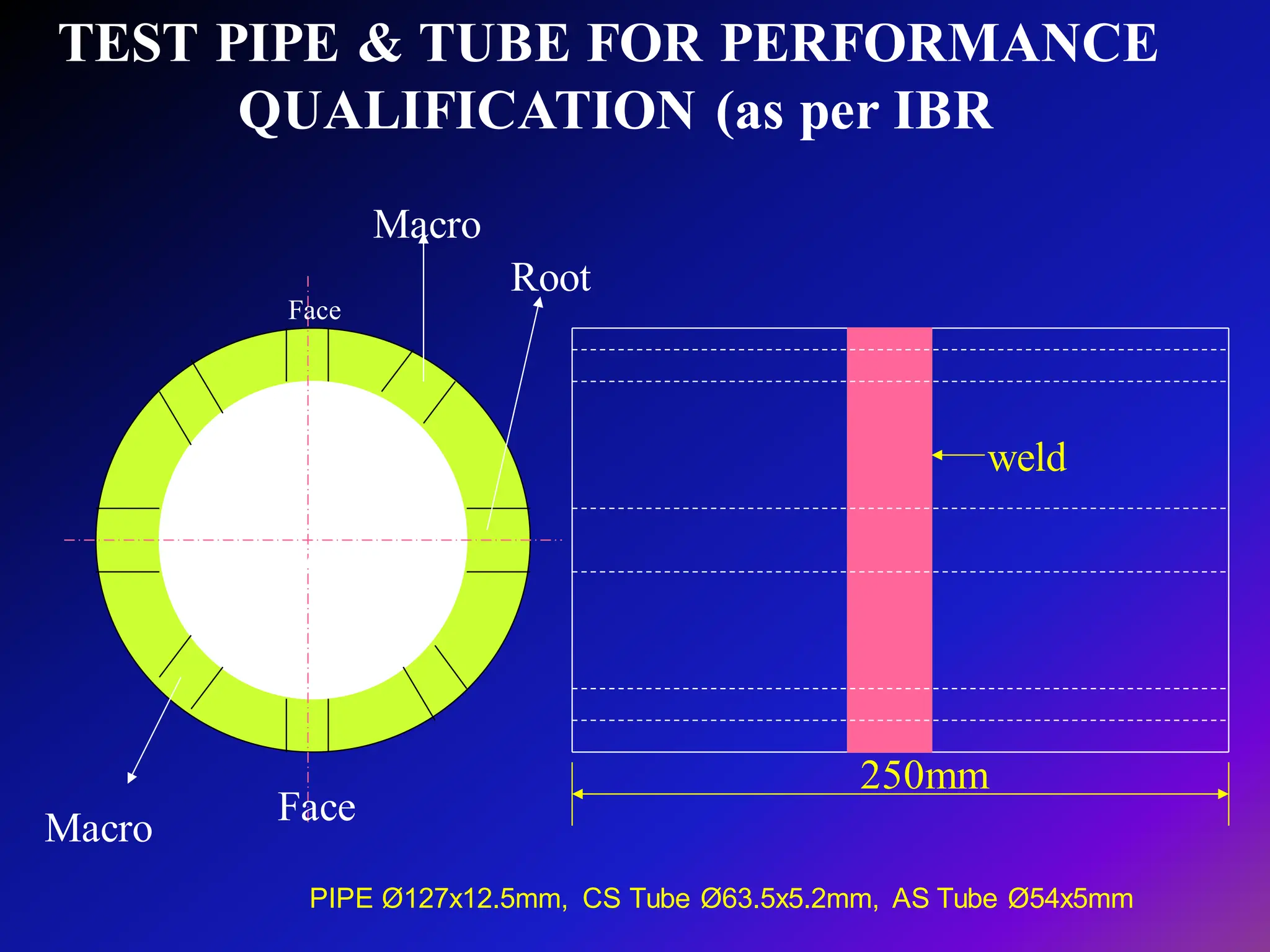

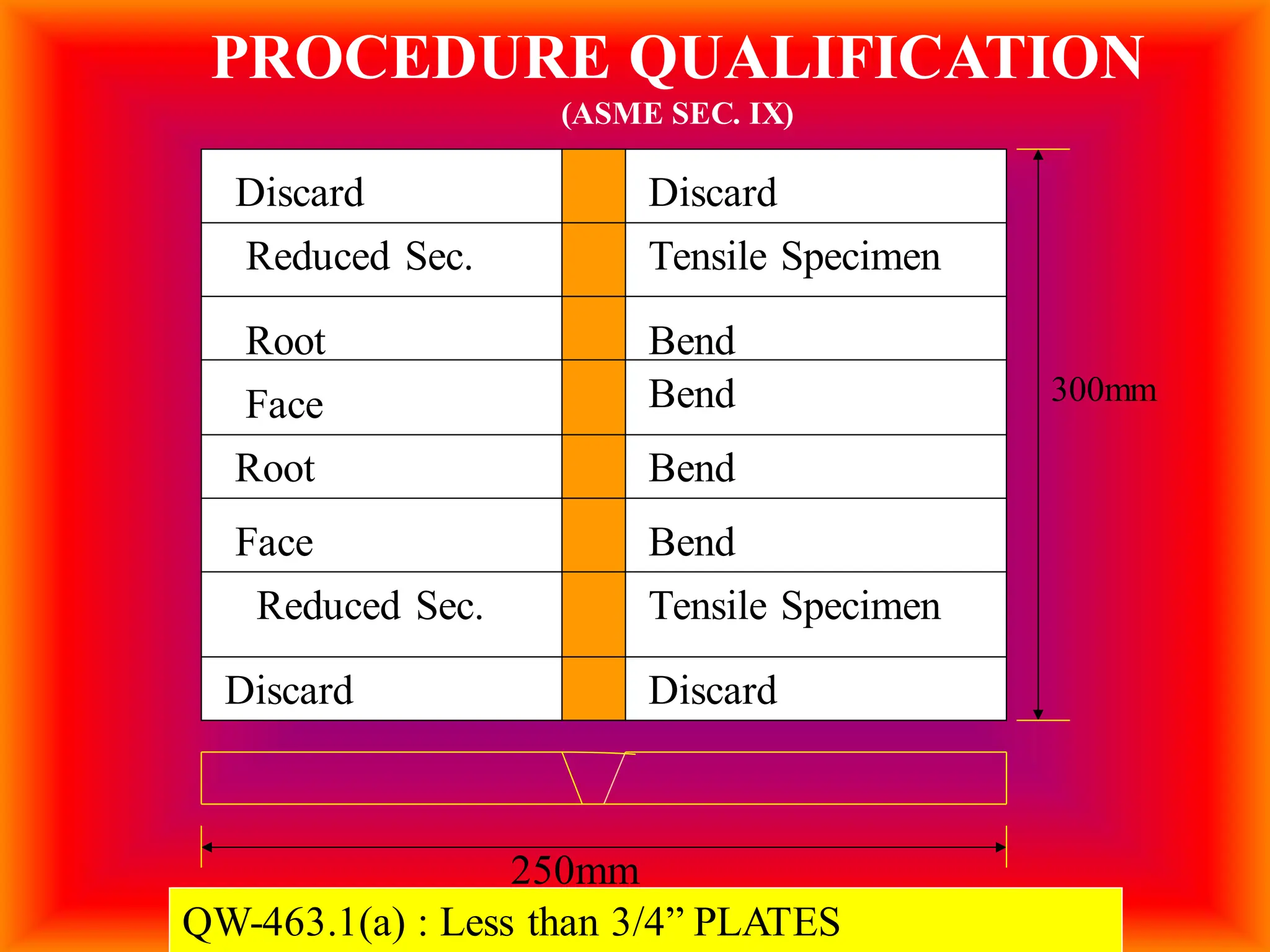

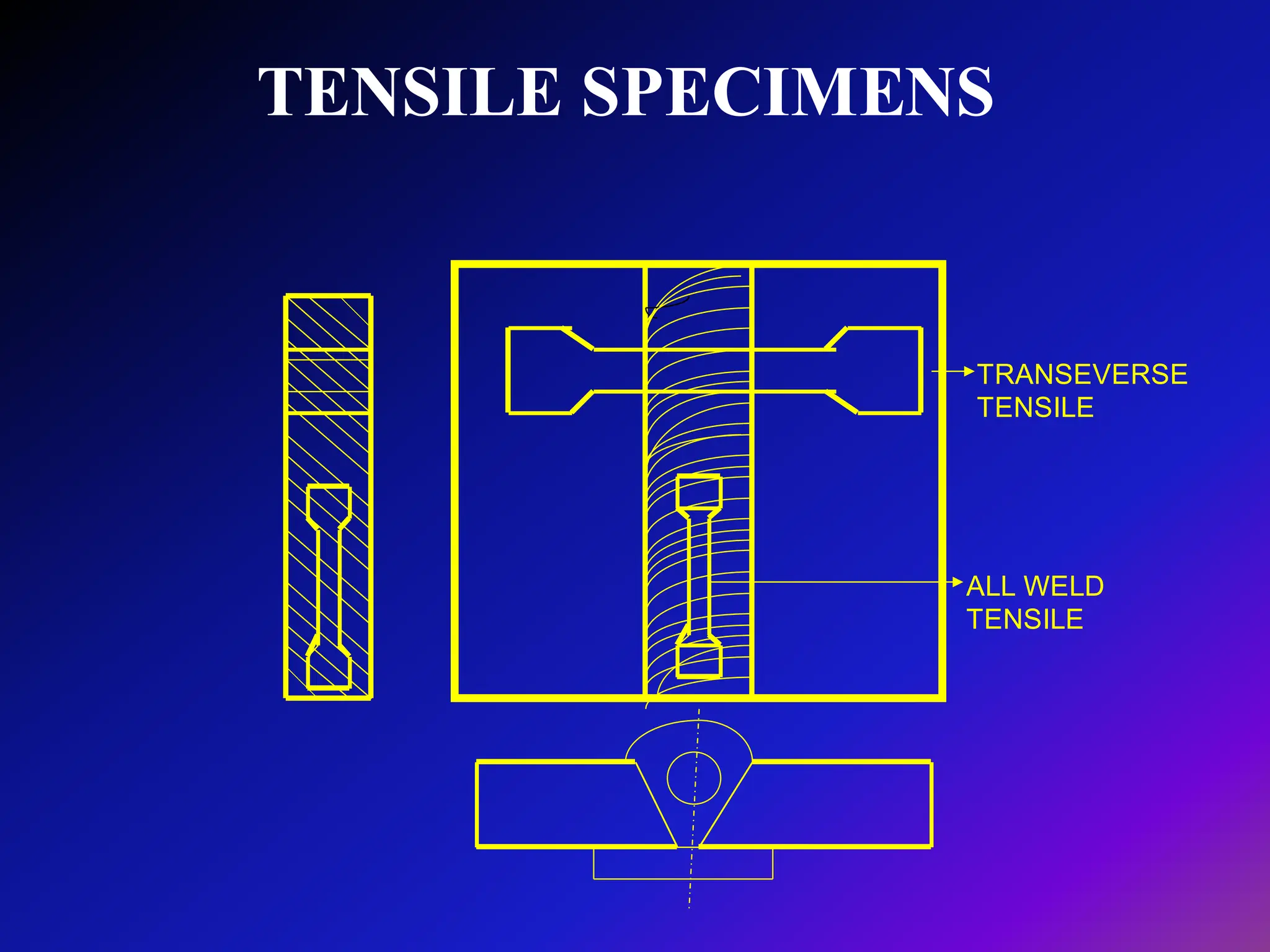

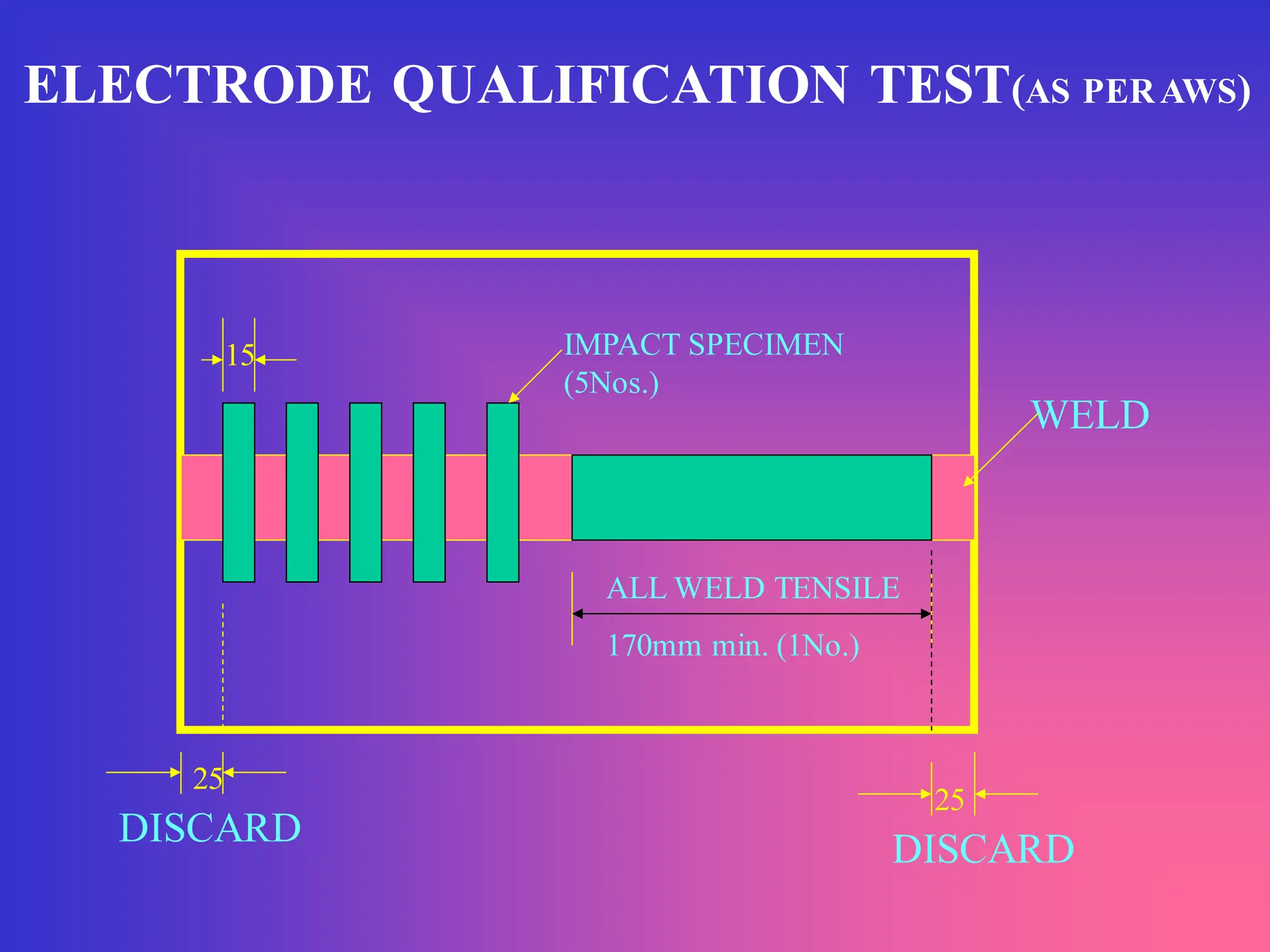

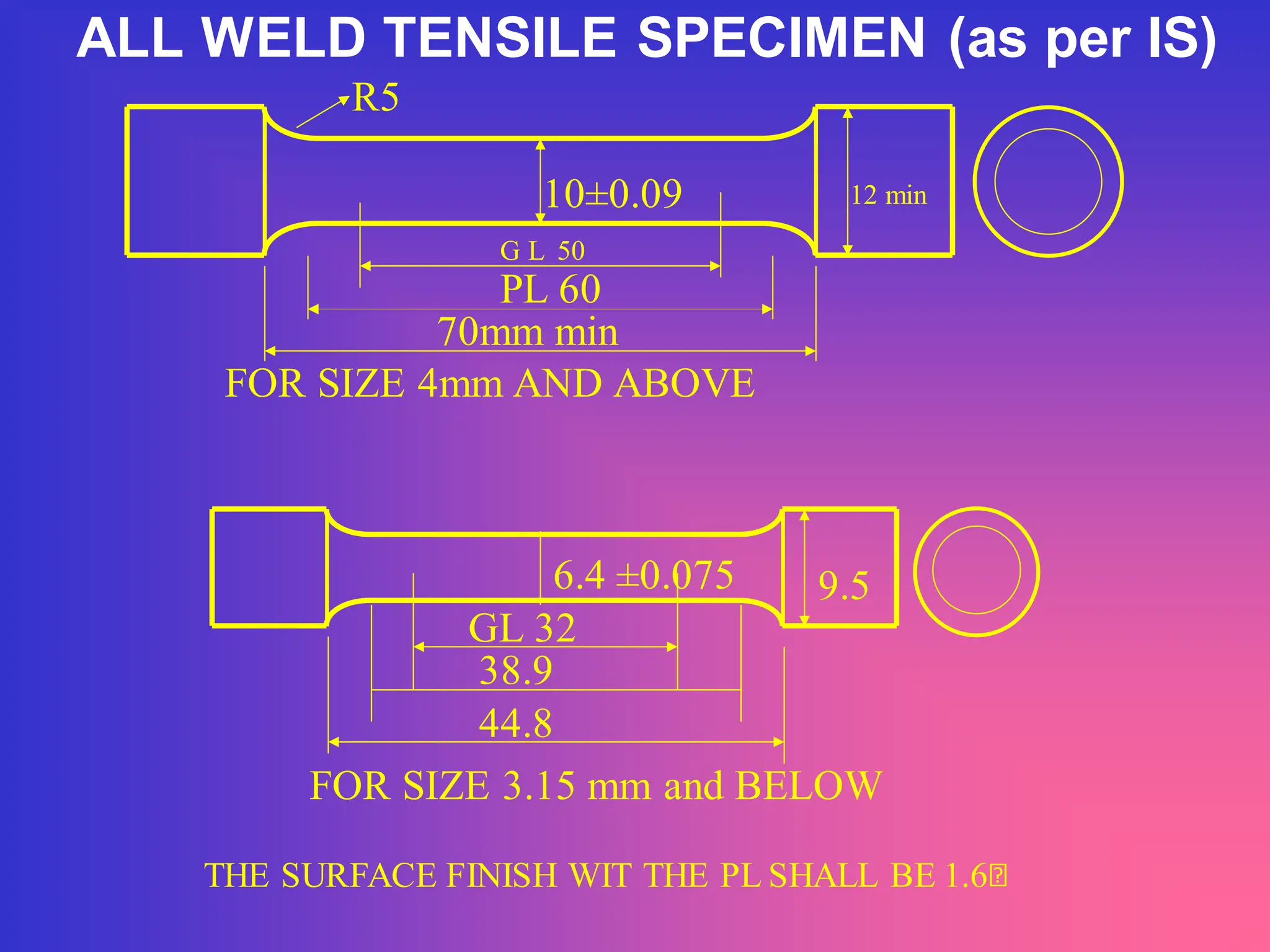

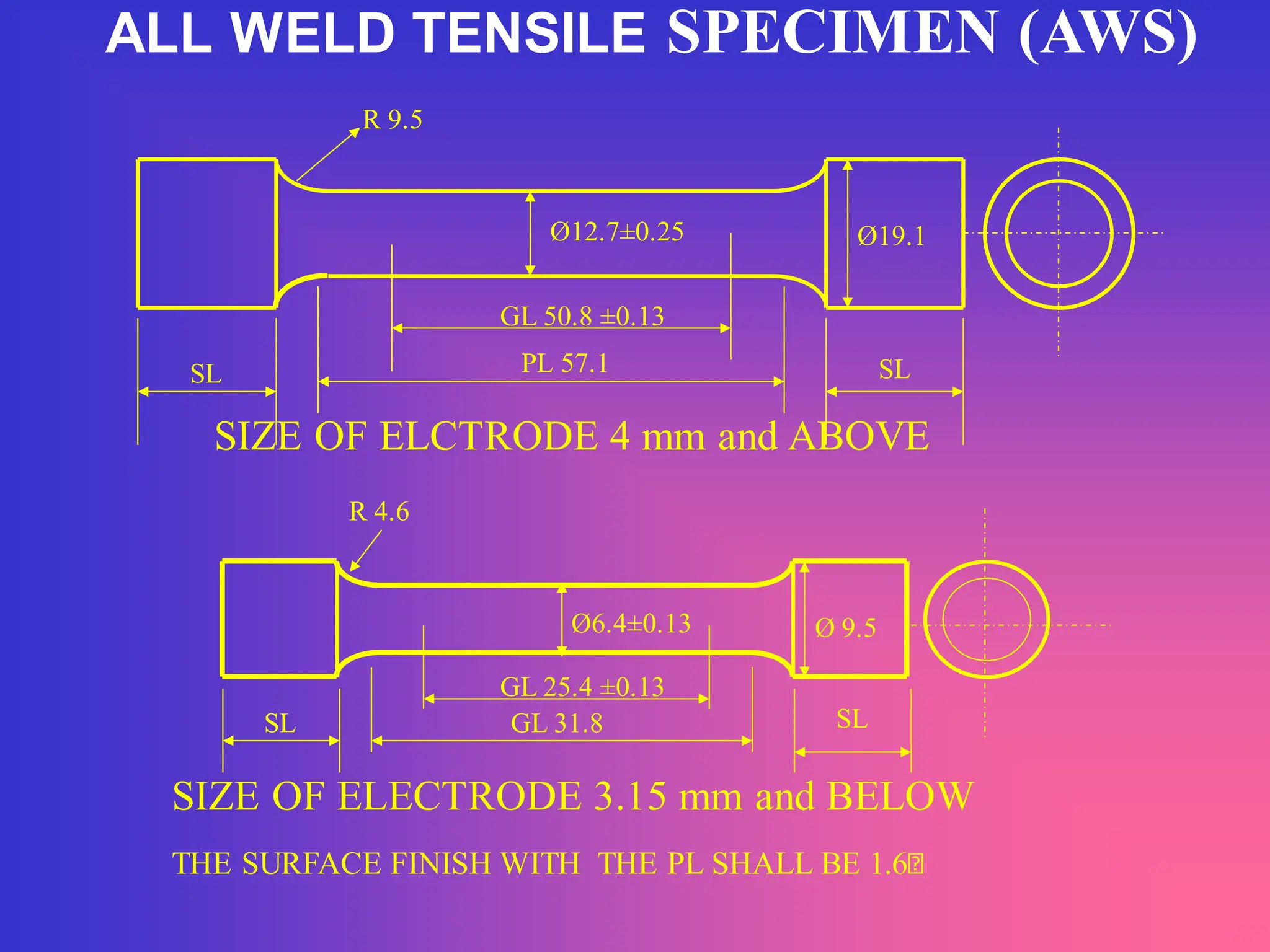

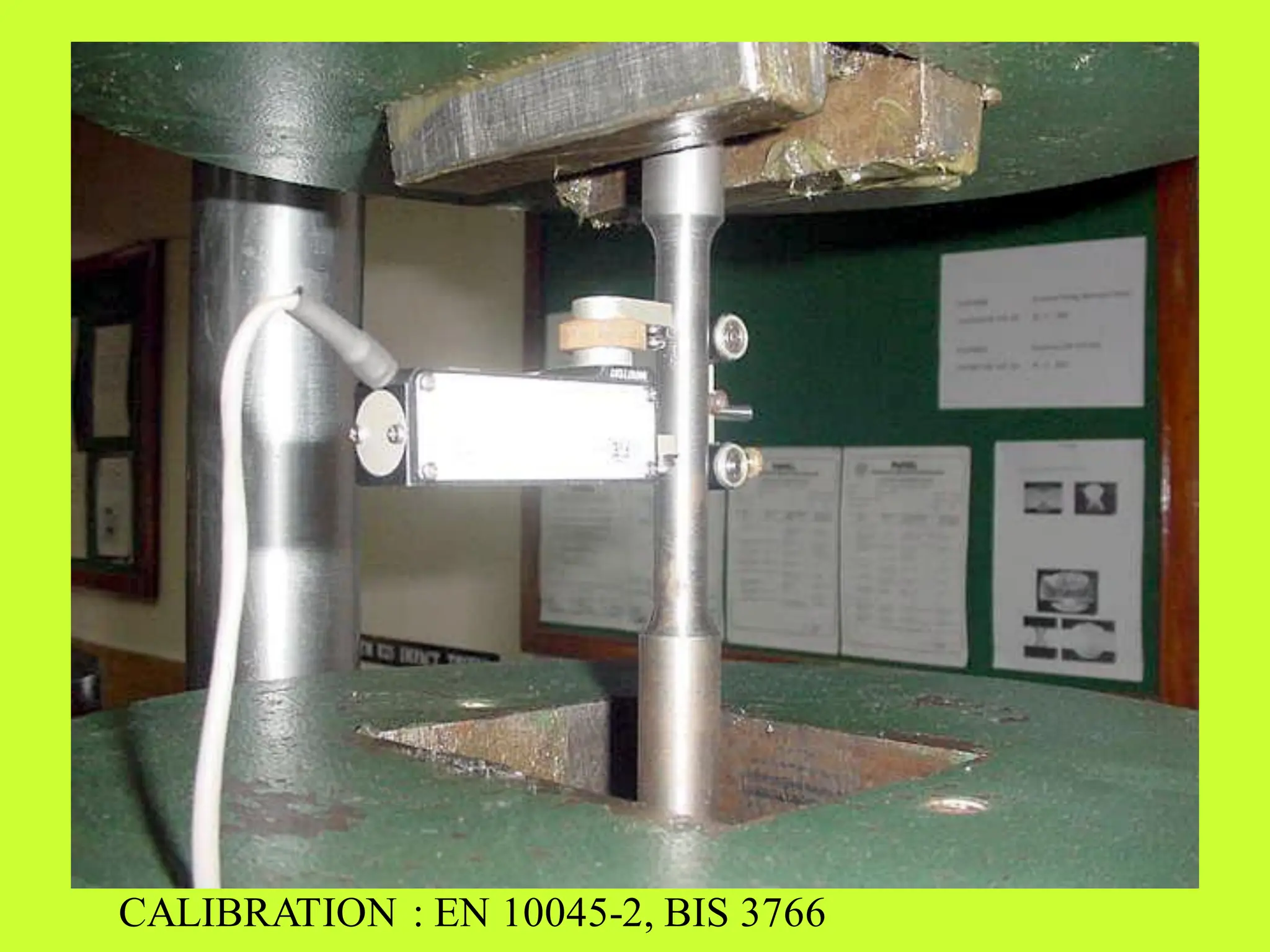

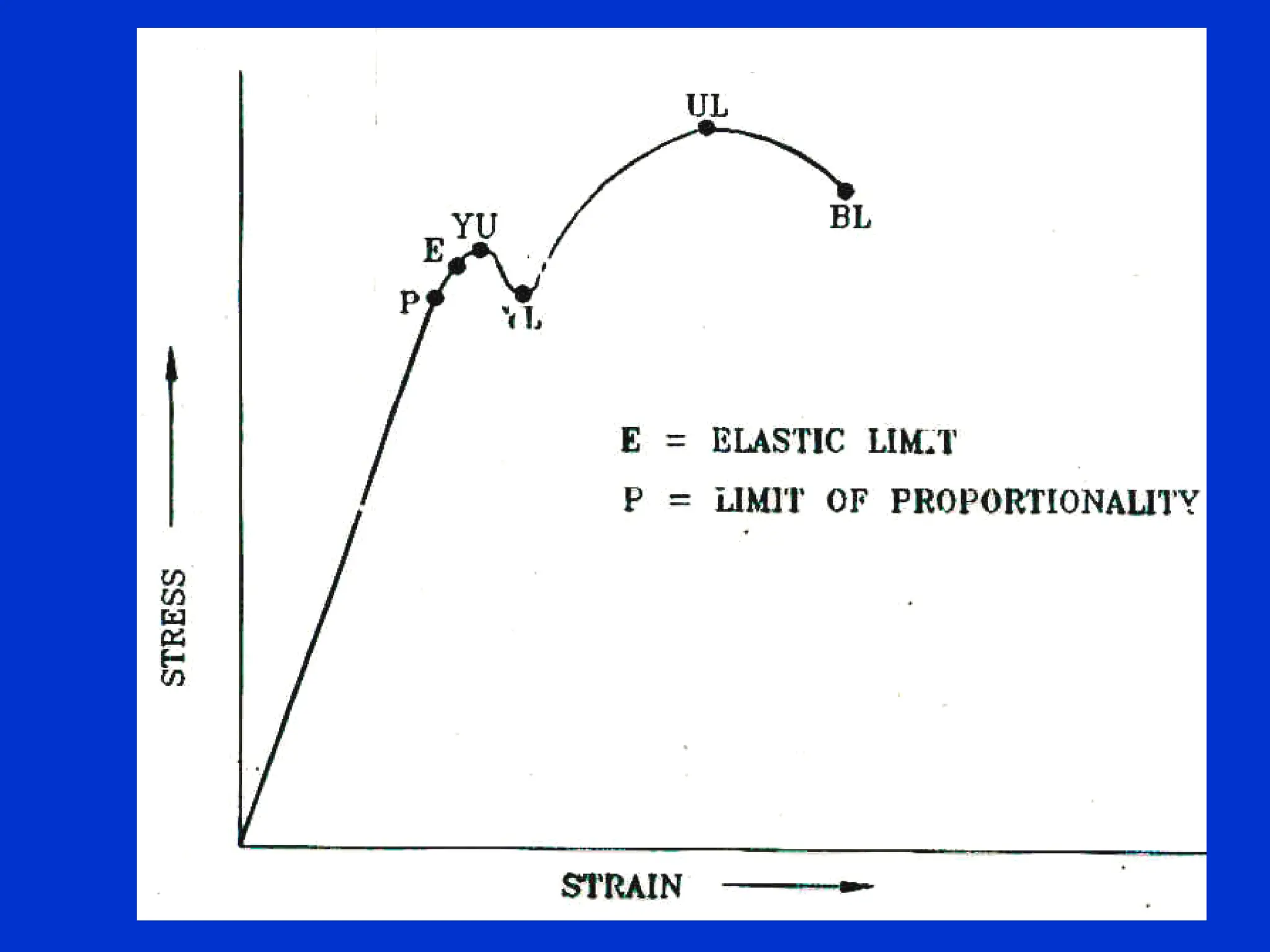

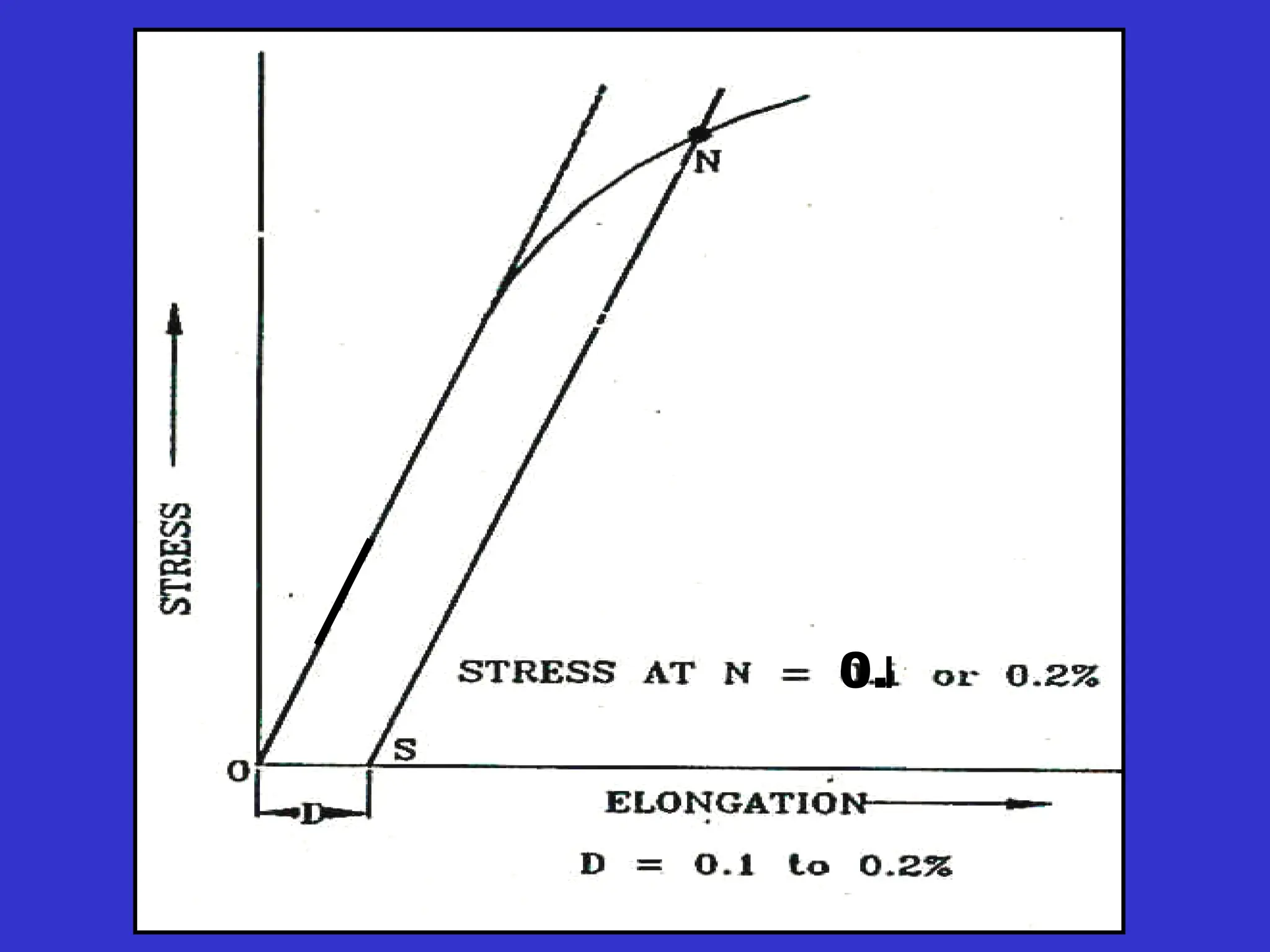

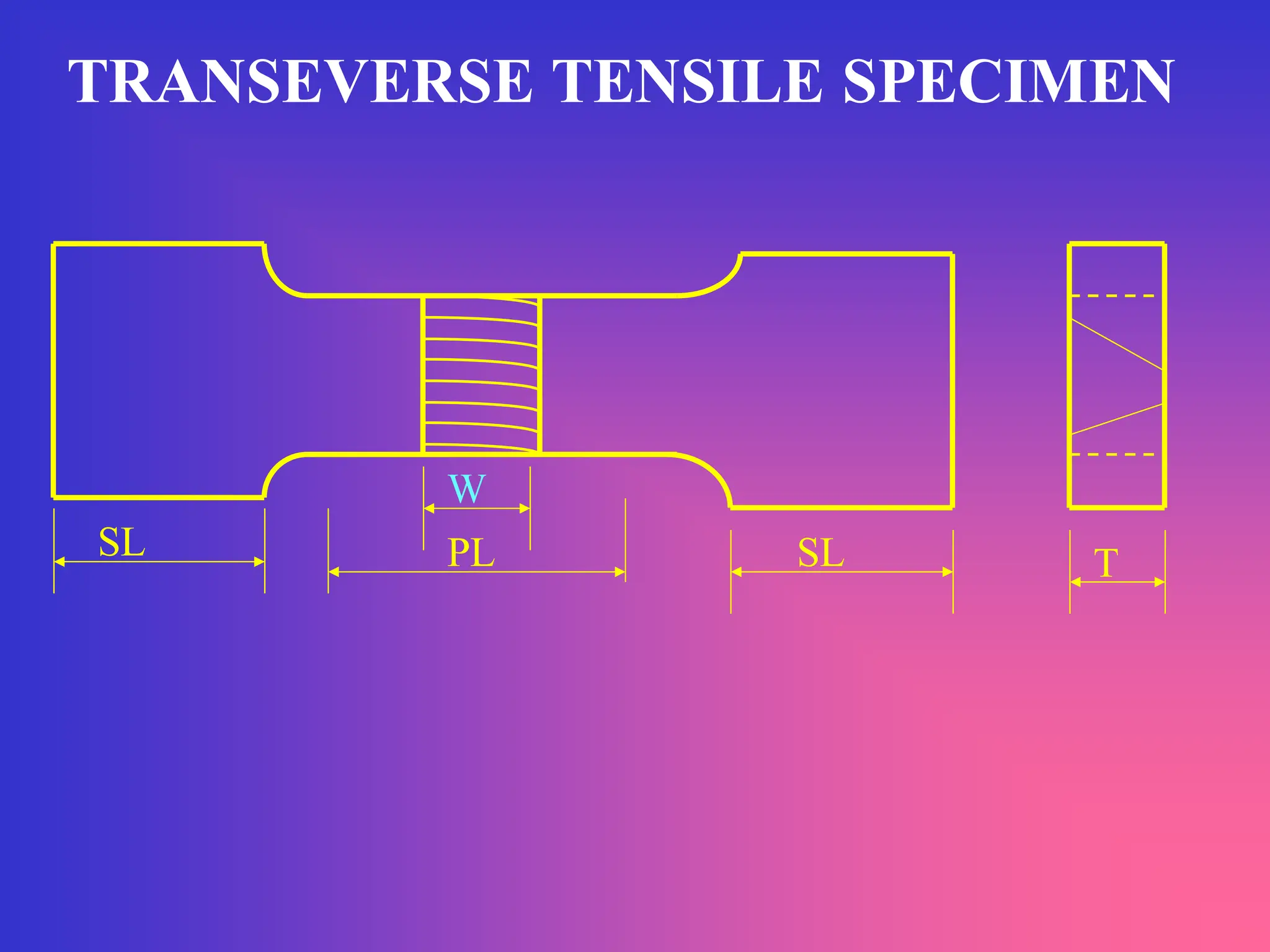

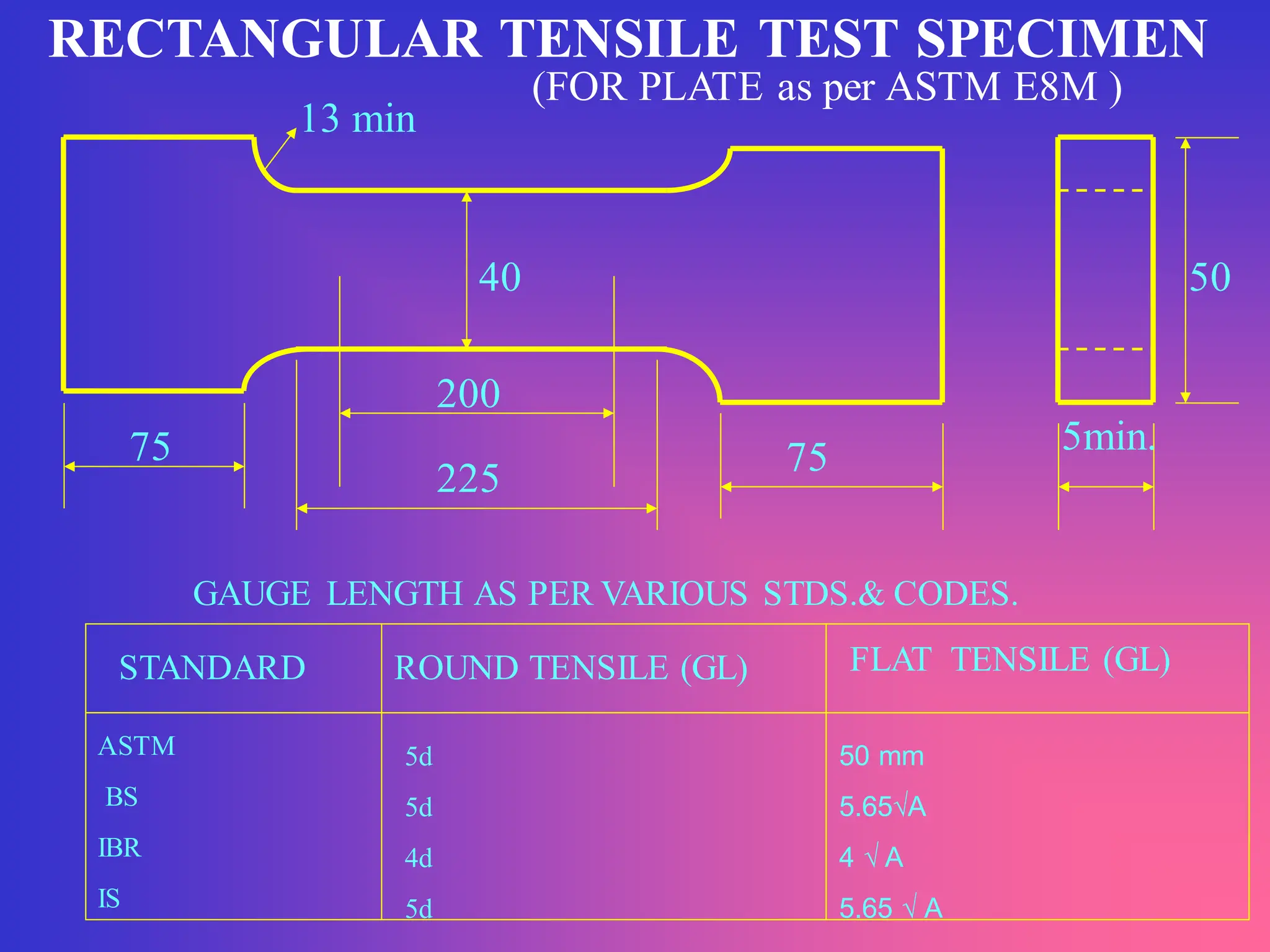

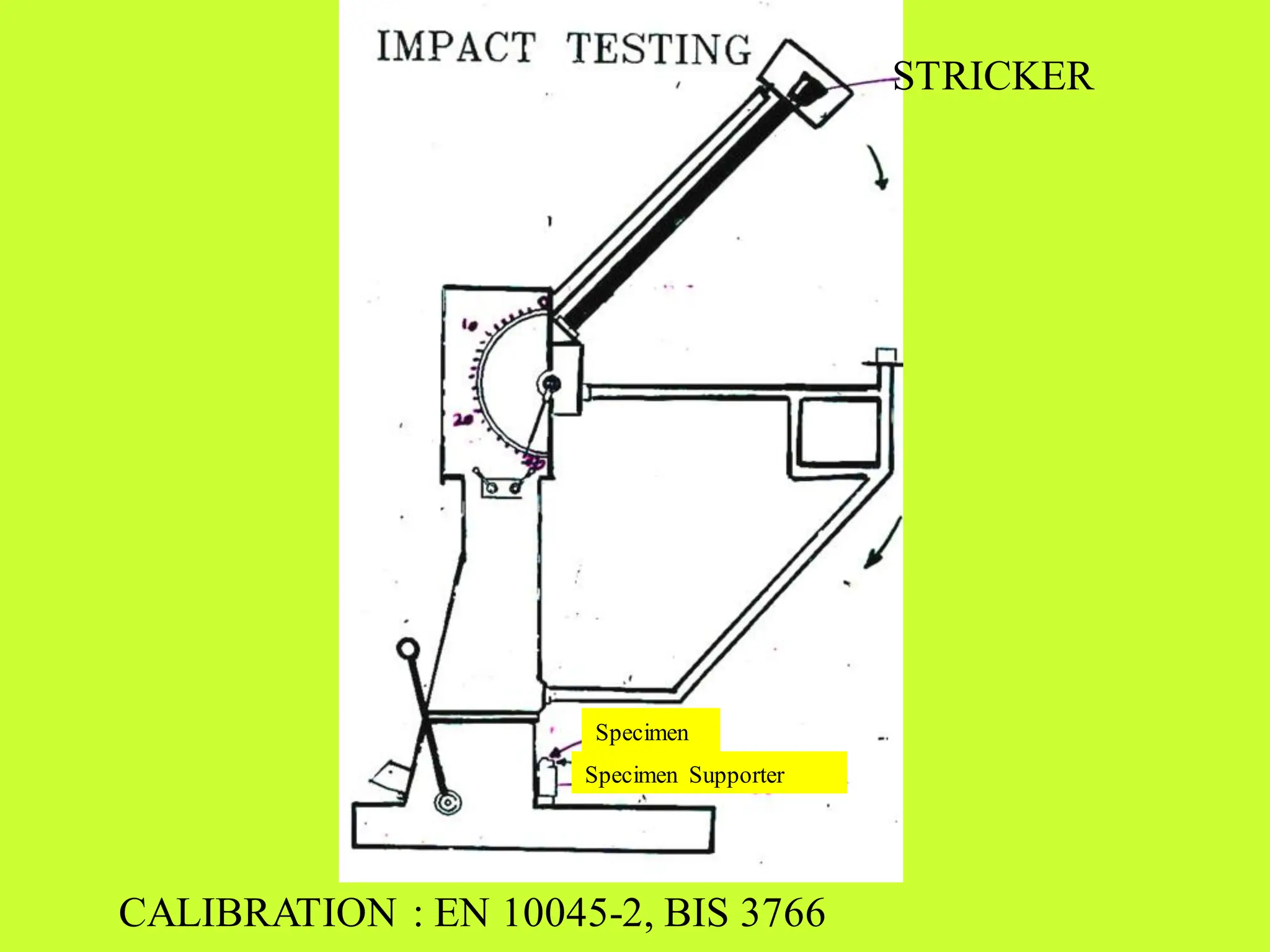

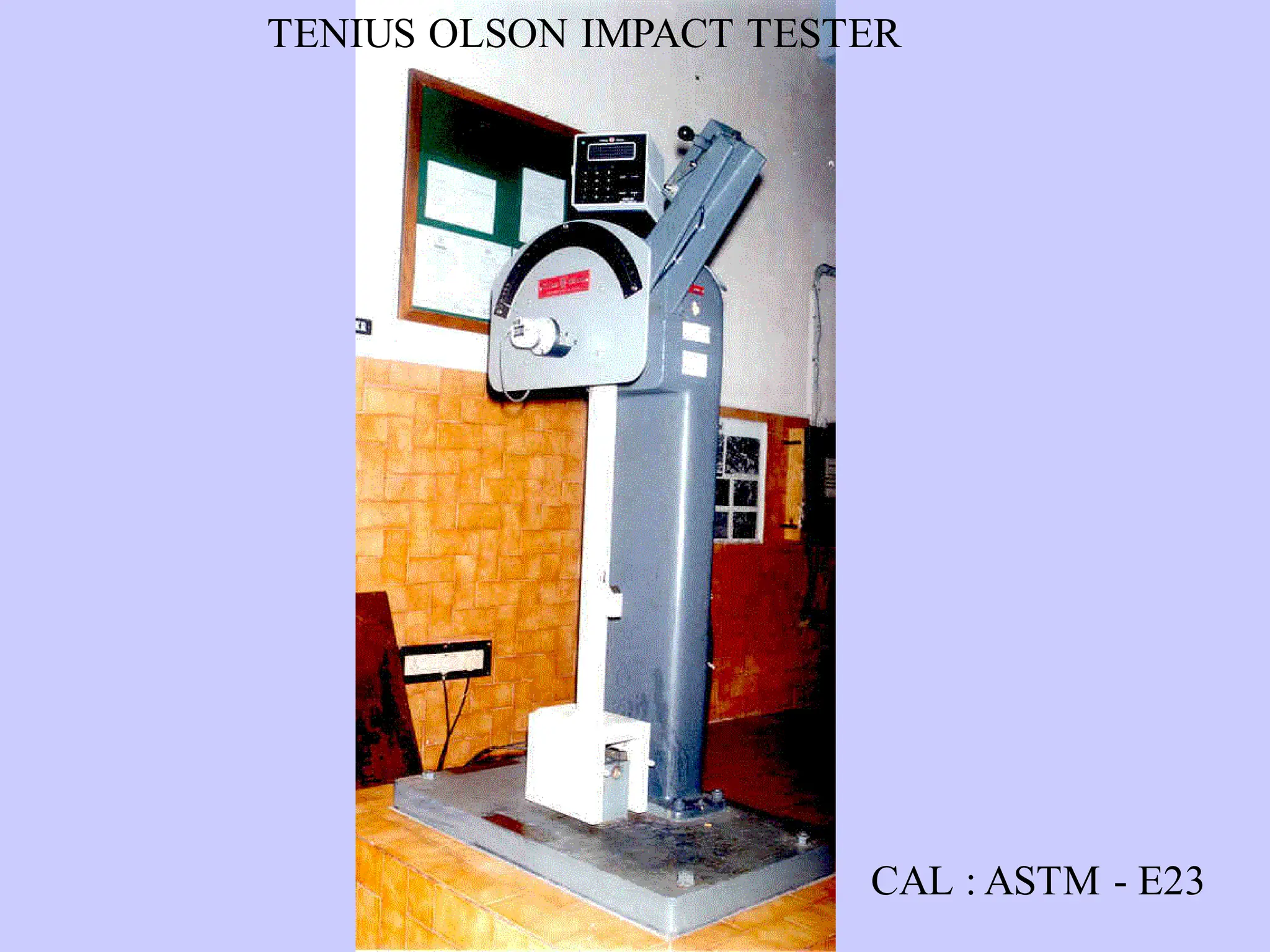

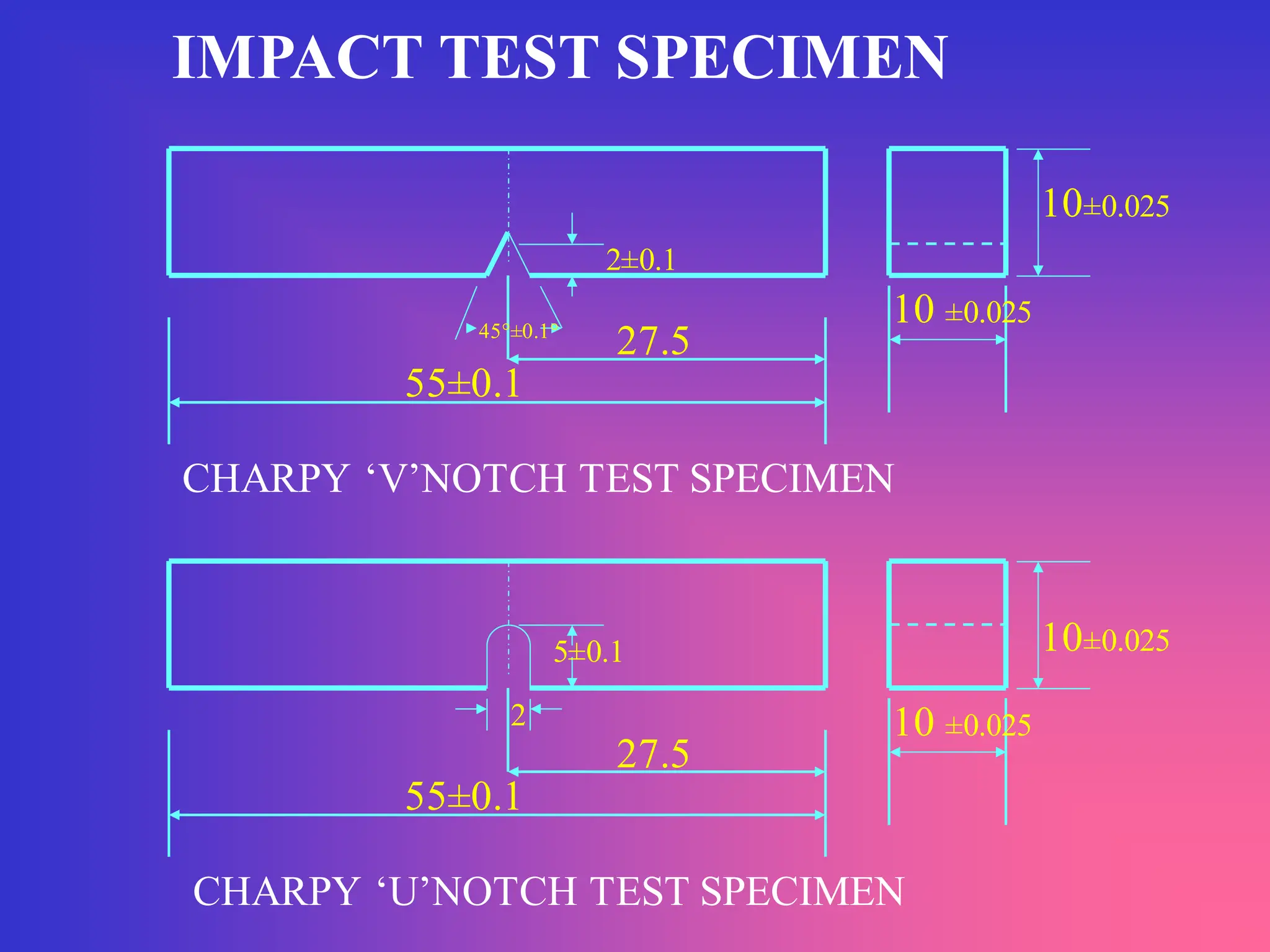

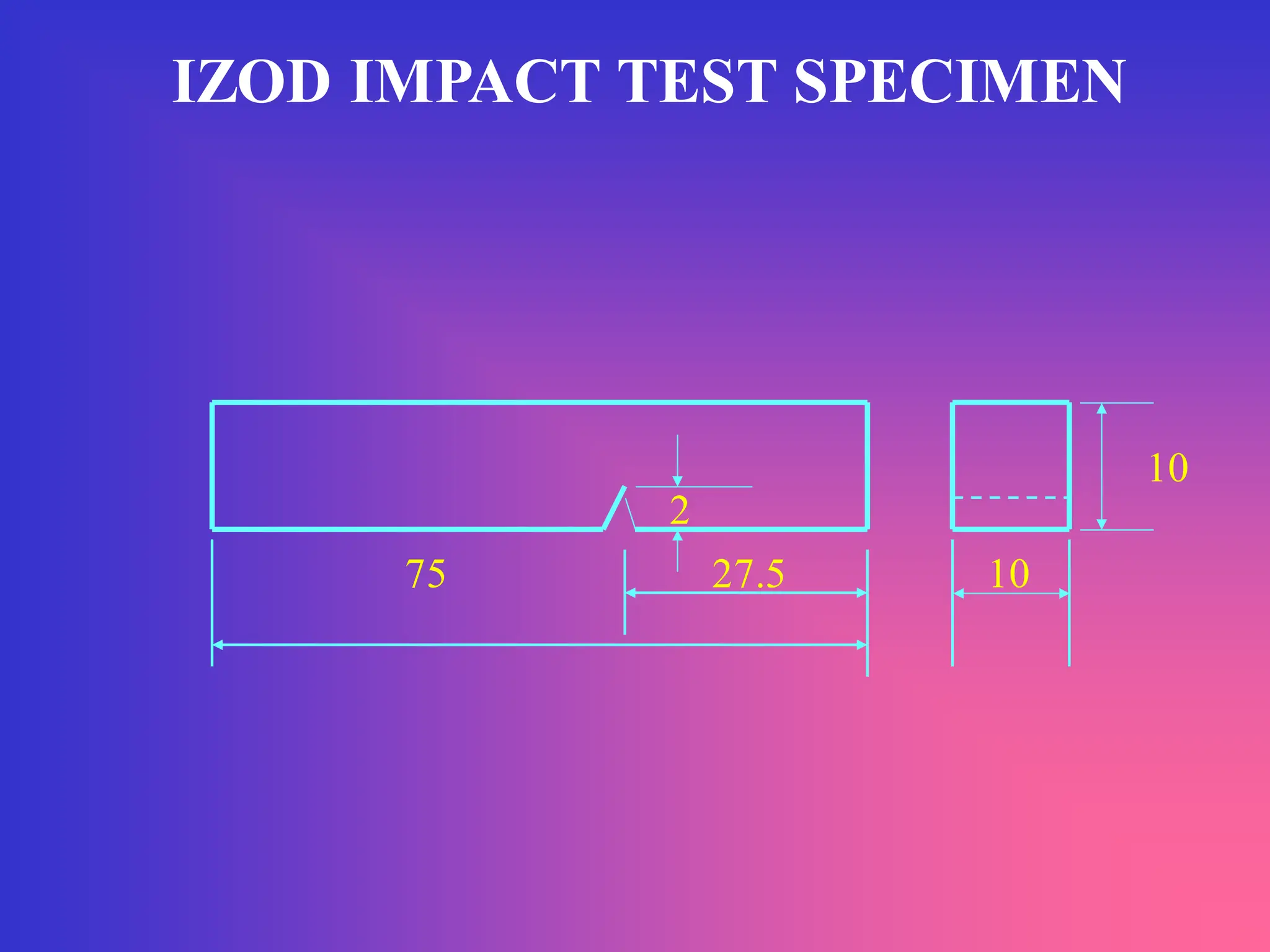

The document details the various destructive testing methods used in mechanical and chemical analysis, including tensile, bend, impact, and hardness tests, along with their purposes. It outlines the standards and codes for mechanical testing, welding qualifications, and the calibration of testing equipment. Additionally, it covers the significance of macro and micro examinations in understanding the structural characteristics of metals and the impact of testing on manufacturing techniques.

![BHN=APPLIED LOAD/AREA OF INDENTATION

BHN=P/[( D/2) X (D- D2 - d2)]

WHERE P=LOAD IN Kg,

D=DIAMETER OF STEEL BALL IN mm, d= DIAMETER OF THE INDENTATION IN mm.

APPLICATION

FOR C.STEEL, CAST IRON,COPPERALLOYS, ALUMINIUM ALLOYS, LEAD AND TIN ETC.

POLISHED SURFACE](https://image.slidesharecdn.com/destructivetestingoverview1717035747-240629193453-585c0186/75/Destructive_Testing_overview_1717035747-pdf-41-2048.jpg)