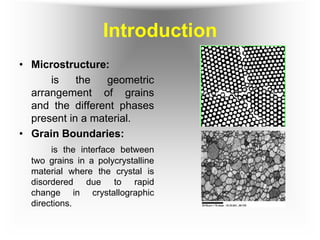

The document provides information on metallographic sample preparation and examination. It discusses objectives like studying microstructure and phases. It describes grinding, polishing, etching, and examining samples under a microscope. The goal is to reveal grain boundaries, phases, and microstructural features. Safety is important when handling corrosive etchants. Proper sectioning, mounting, grinding, polishing and etching allows examination of material properties at the microscopic level.