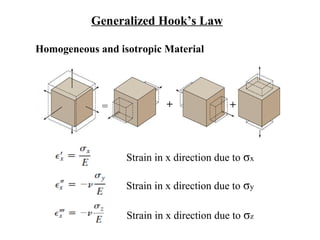

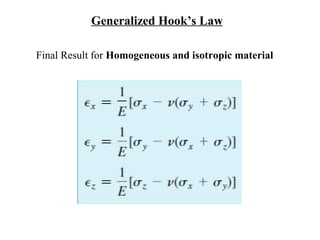

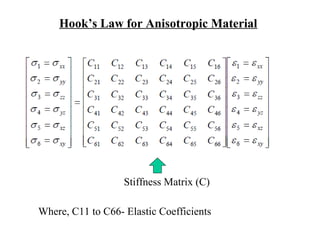

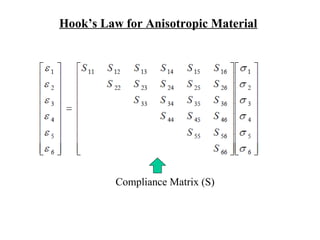

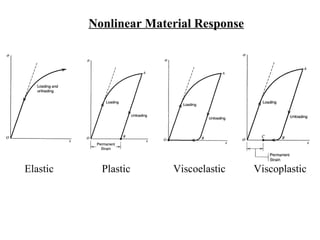

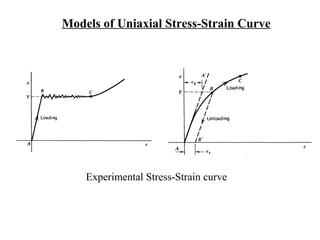

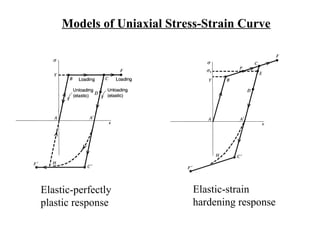

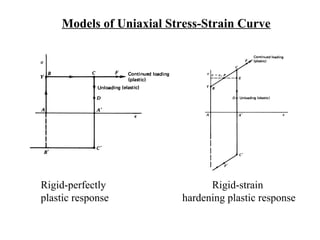

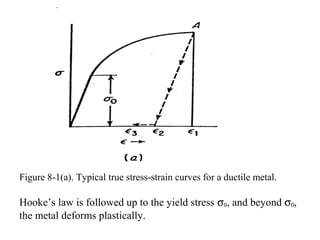

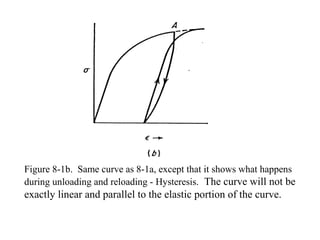

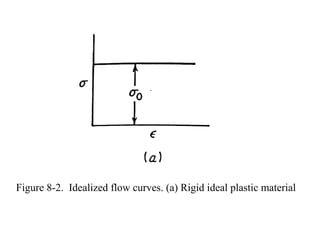

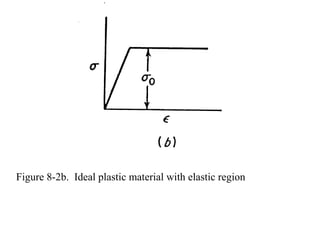

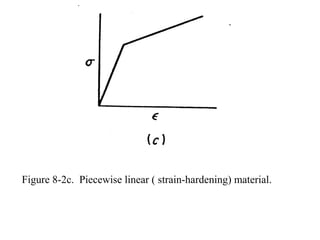

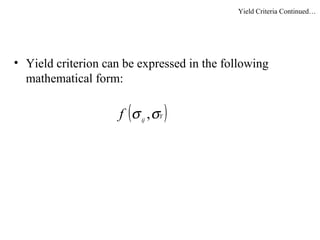

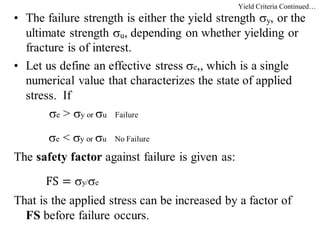

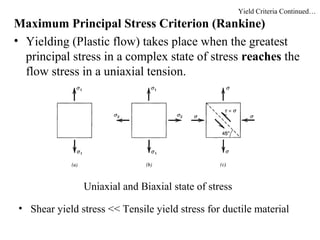

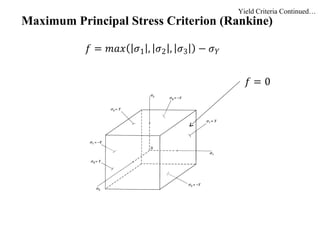

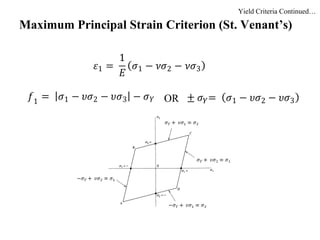

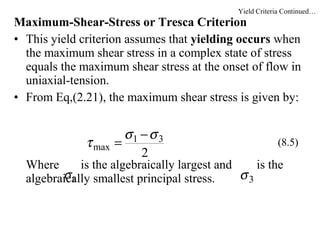

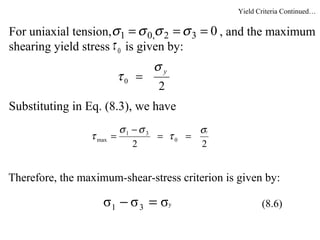

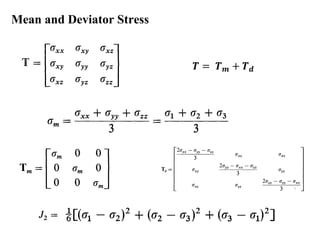

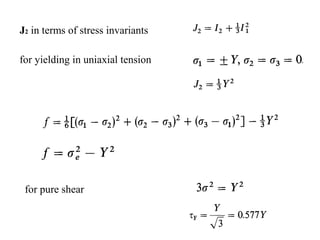

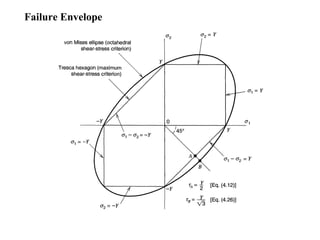

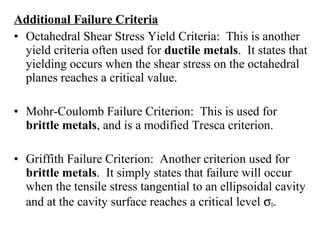

The document discusses plasticity theory and yield criteria. It introduces Hooke's law and its limitations under large strains. Generalized Hooke's law is presented for isotropic and anisotropic materials. Common stress-strain curves are shown including elastic-plastic and strain hardening responses. Several yield criteria are covered, including maximum principal stress, Tresca, and von Mises criteria. The von Mises criterion uses a second invariant of stress to predict yielding of ductile materials. An example compares predictions of yielding using Tresca and von Mises criteria for a given stress state in aluminum.

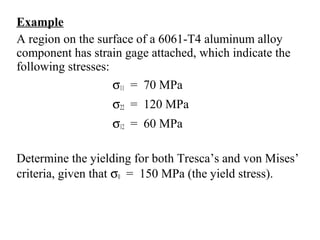

![von Mises’ or Distortion-Energy Criterion

• This criterion is usually applied to ductile material

• von Mises’ proposed that yielding would occur when

the second invariant of the stress deviator J2 exceeds

some critical value.

where

2

2 kJ =

( ) ( ) ( )[ ]2

13

2

21

2

322

6

1

σσσσσσ −+−+−=J (8.7)](https://image.slidesharecdn.com/unit2theoryofplasticity-180529055649/85/Unit-2-theory_of_plasticity-30-320.jpg)

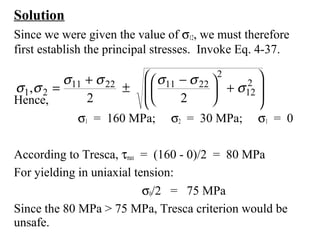

![The von Mises criterion can be invoked from Eq. 8-9.

The L.H.S. of the above Eq. gives a value of 175 MPa.

This criterion predicts that the material will not fail (flow),

unlike the Tresca criterion, which predicts that the material

will flow.

Therefore, the Tresca criterion is more conservative than

the von Mises’ criterion in predicting failure.

[ ] 2/12

13

2

32

2

21 )()()(

2

1

σσσσσσσ −+−+−=o](https://image.slidesharecdn.com/unit2theoryofplasticity-180529055649/85/Unit-2-theory_of_plasticity-38-320.jpg)