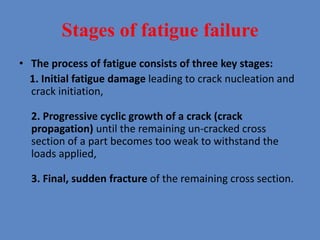

The document discusses fatigue testing and the phenomenon of material fatigue, which causes failure due to repeated cyclic stresses below a material's ultimate strength. It outlines types of fatigue failure, stages leading to crack propagation, and the importance of conducting fatigue tests to determine the fatigue limit. The fatigue limit, or endurance limit, is defined as the stress level that allows infinite loading cycles without failure.