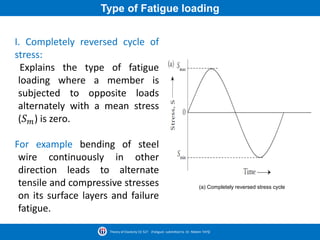

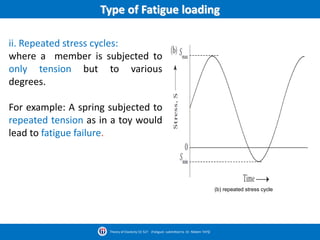

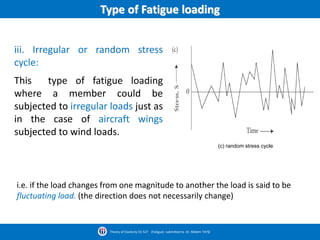

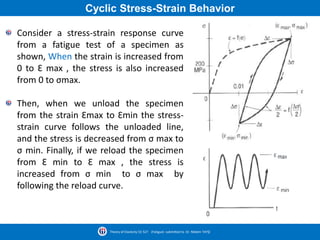

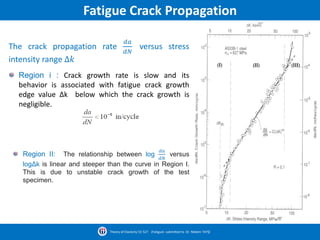

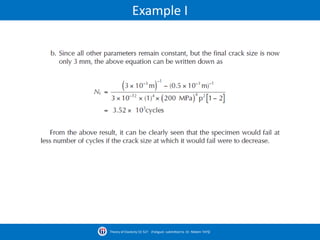

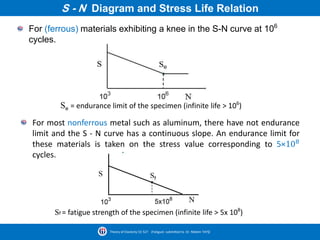

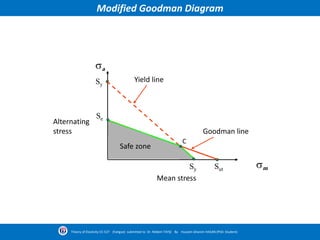

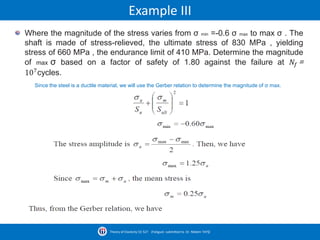

Fatigue occurs when a material is subjected to repeated cyclic stresses that cause cracks to form over time even when the stresses are much lower than the material's strength. The document discusses various types of fatigue loading and summarizes key concepts like fatigue life diagrams, factors that influence fatigue crack growth rates, and methods for analyzing fatigue failure. It provides examples of calculating stress levels to avoid fatigue failure based on a given number of cycles.