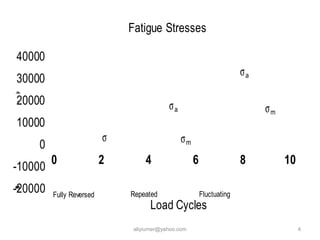

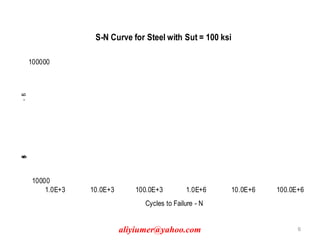

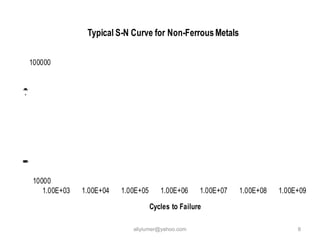

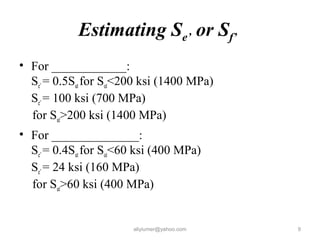

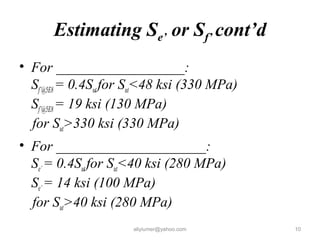

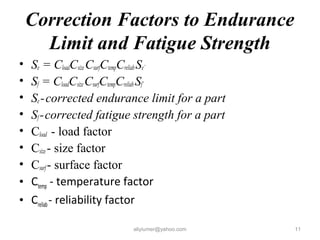

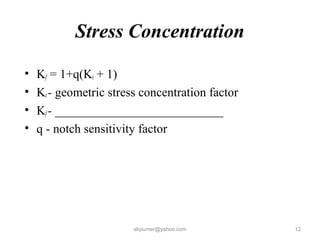

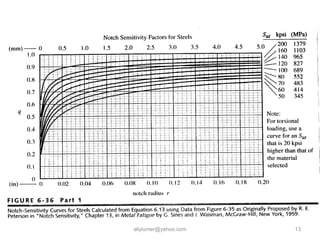

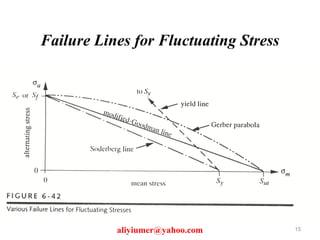

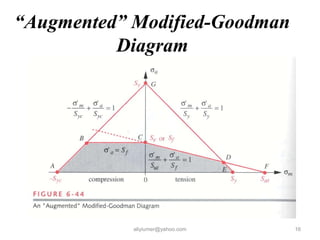

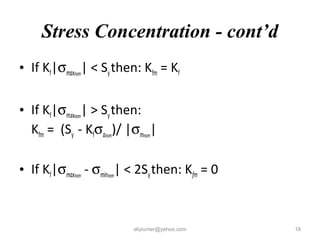

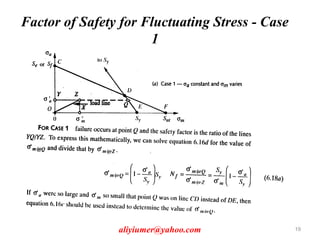

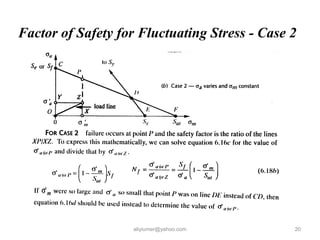

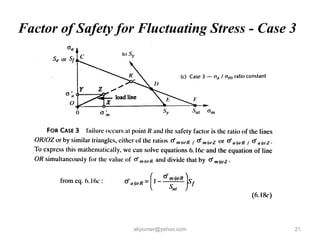

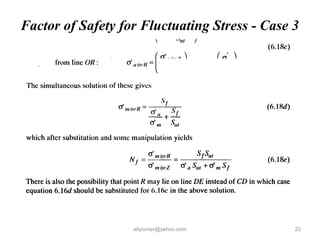

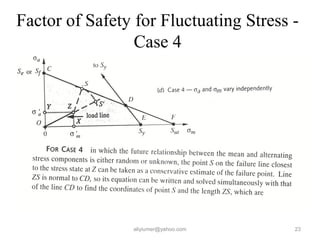

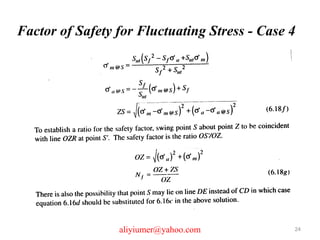

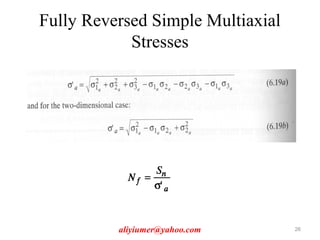

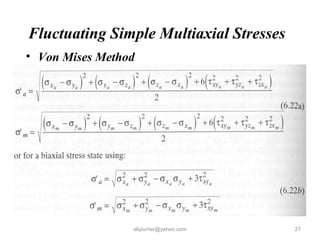

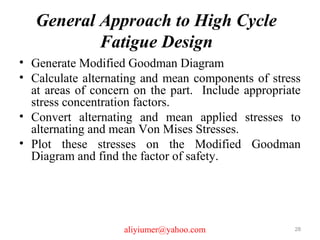

This document discusses various fatigue failure theories including stress-life and strain-life models. It describes how fatigue occurs due to cyclic stresses and starts with a small crack that propagates over time. It also covers fatigue strength, endurance limits, S-N curves, stress concentration factors, Goodman diagrams and multiaxial stresses as they relate to fatigue failure analysis. Estimation techniques are provided for determining fatigue strength and endurance limits of various materials.