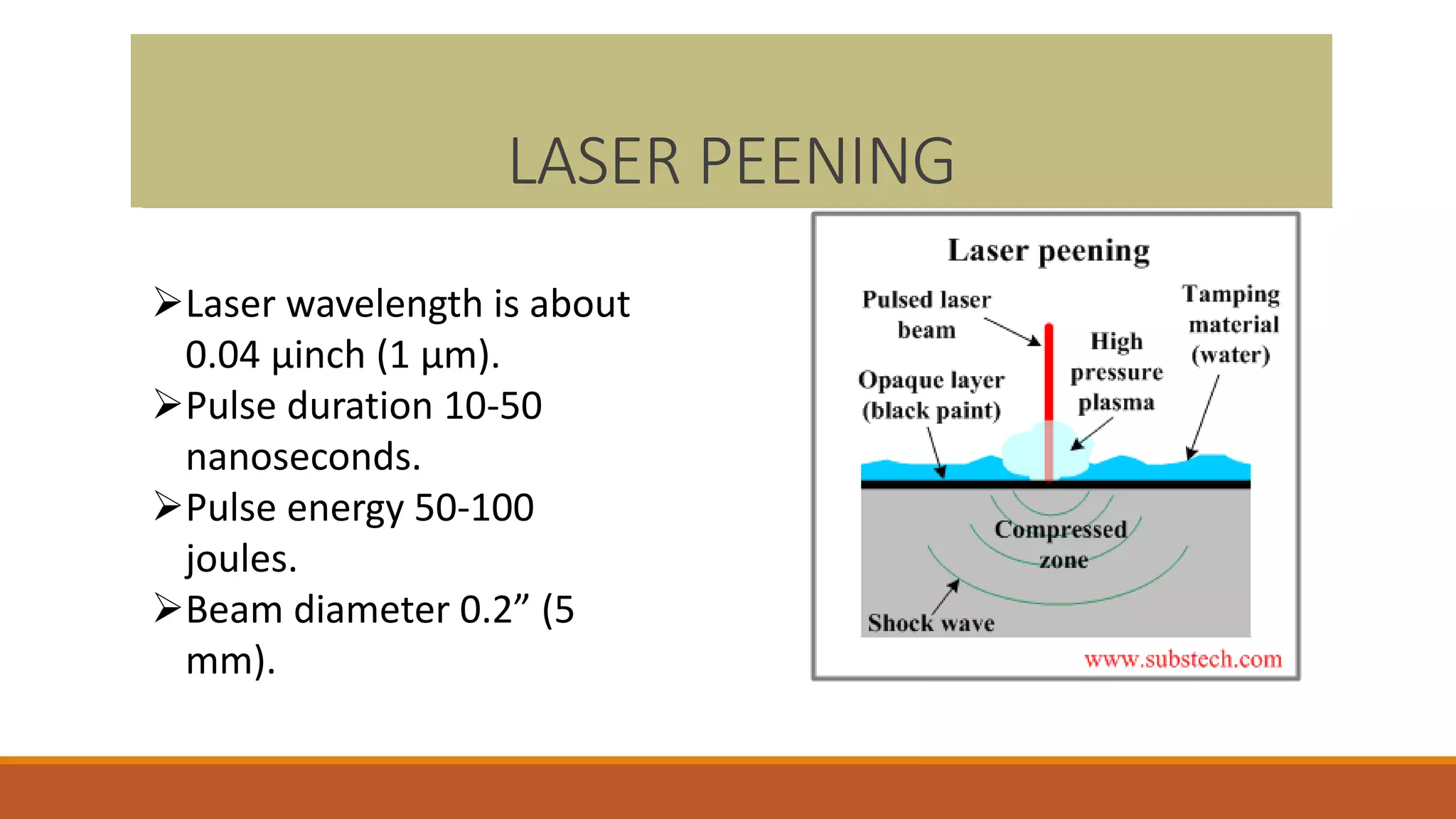

This document discusses residual stresses, which are stresses that remain in a solid material after the original cause of stress is removed. Residual stresses can be desirable or undesirable. Common sources of residual stresses include casting, welding, machining, heat treatment, and plastic deformation during bending, rolling, and forging. Two methods for imparting beneficial compressive residual stresses are laser peening and shot peening. Various techniques for measuring residual stresses are also outlined such as X-ray diffraction, ultrasonic methods, and the hole drilling strain gage technique.