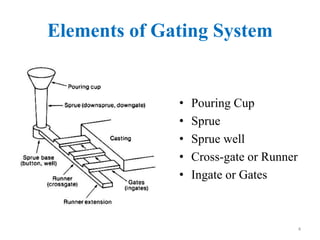

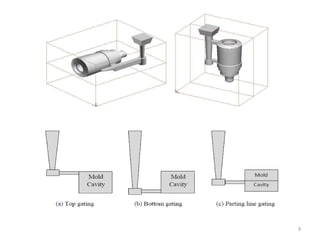

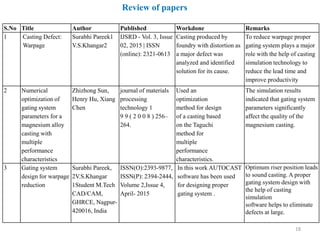

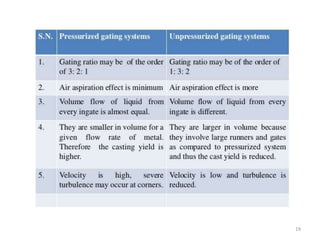

The document summarizes a seminar presentation on gating systems for metal casting. It defines the key elements of a gating system including the pouring cup, sprue, sprue well, runner, and gates. It describes the functions of a gating system to fill the mold cavity smoothly and prevent defects. It also discusses types of gates, pouring time, gating ratio, guidelines for design, and concludes that an optimized gating system can improve casting quality and yield by reducing warping. It reviews several papers on topics like reducing warping through gating system design, optimizing gating parameters for magnesium alloys, and using simulation software to design gating systems.