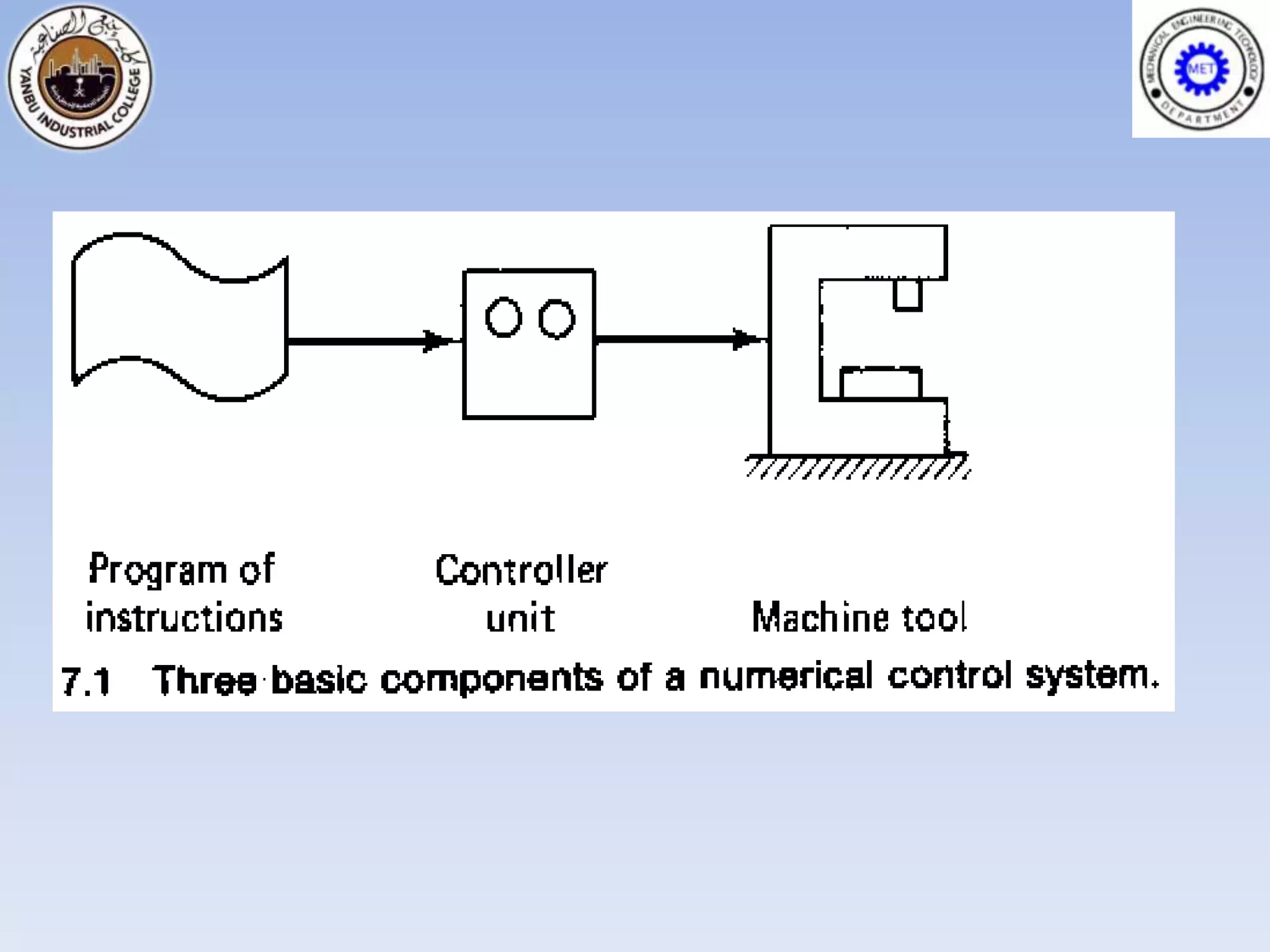

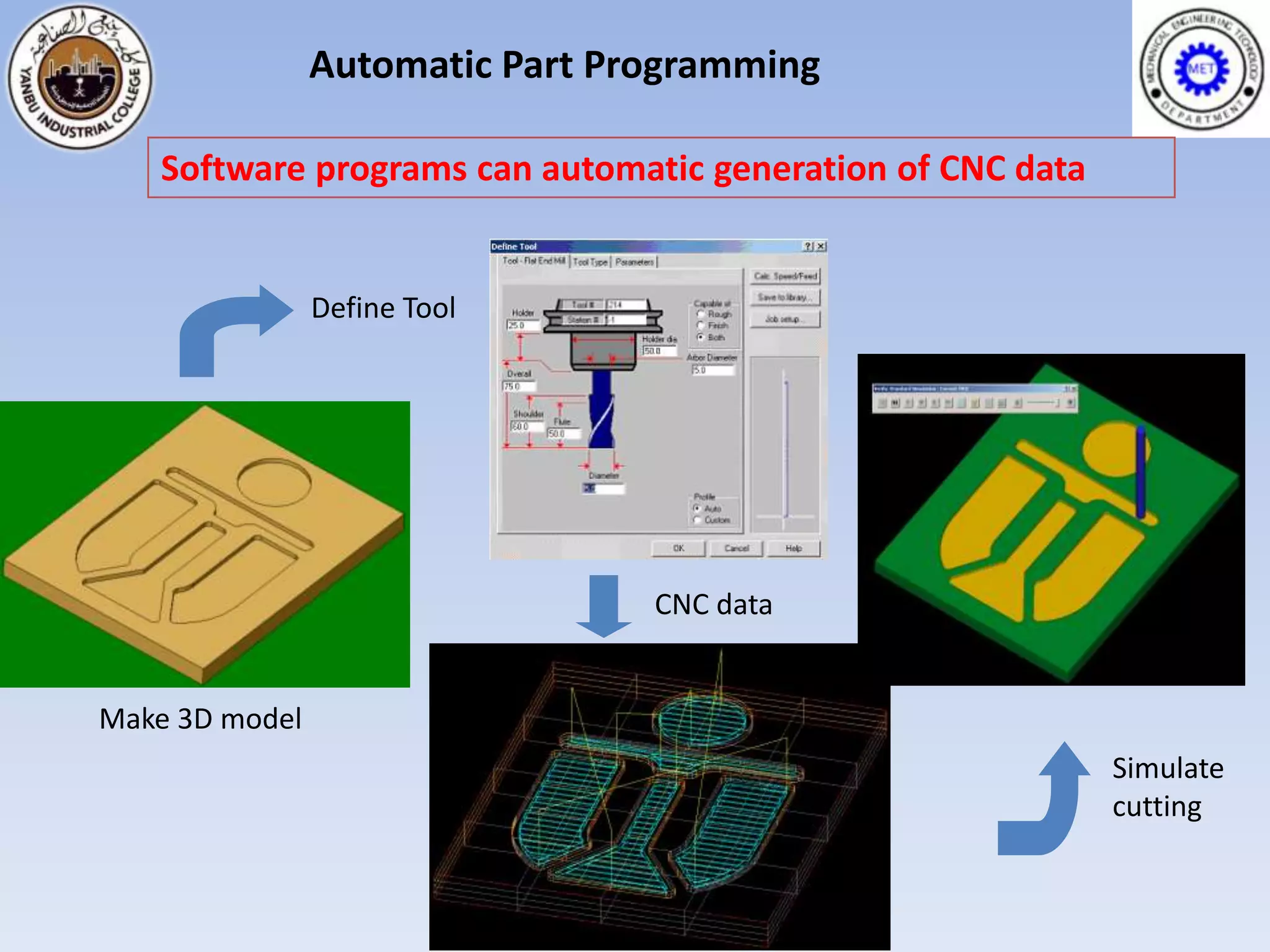

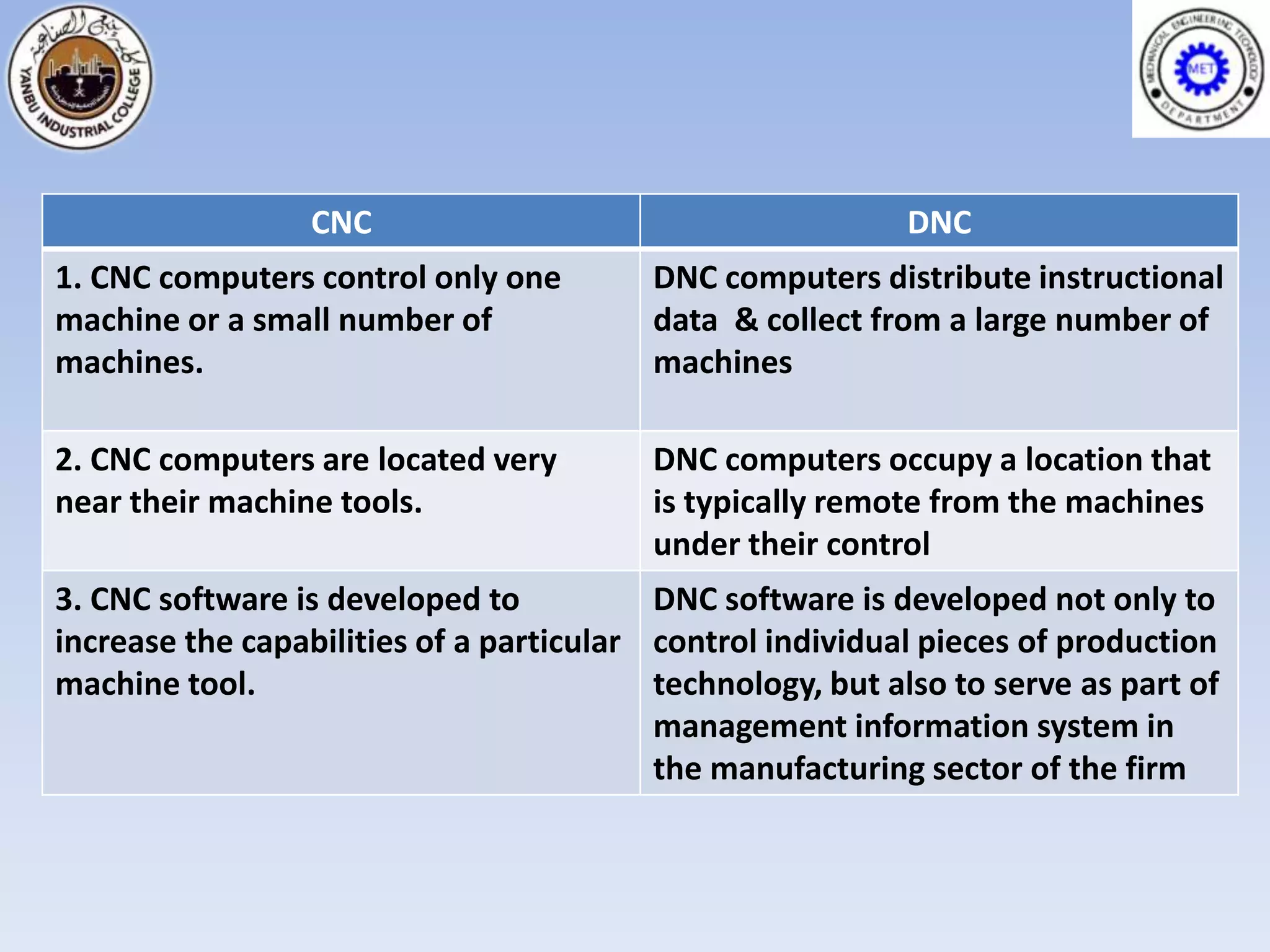

The document discusses numerical control, computer numeric control (CNC), direct numeric control (DNC), and automatic part programming. CNC uses computer programs to control machine functions like cutting speed, feed, and tool selection. DNC allows a central computer to control over 100 machines through direct connection. Automatic part programming software can generate CNC data by defining tools and making a 3D model of the part to be cut.