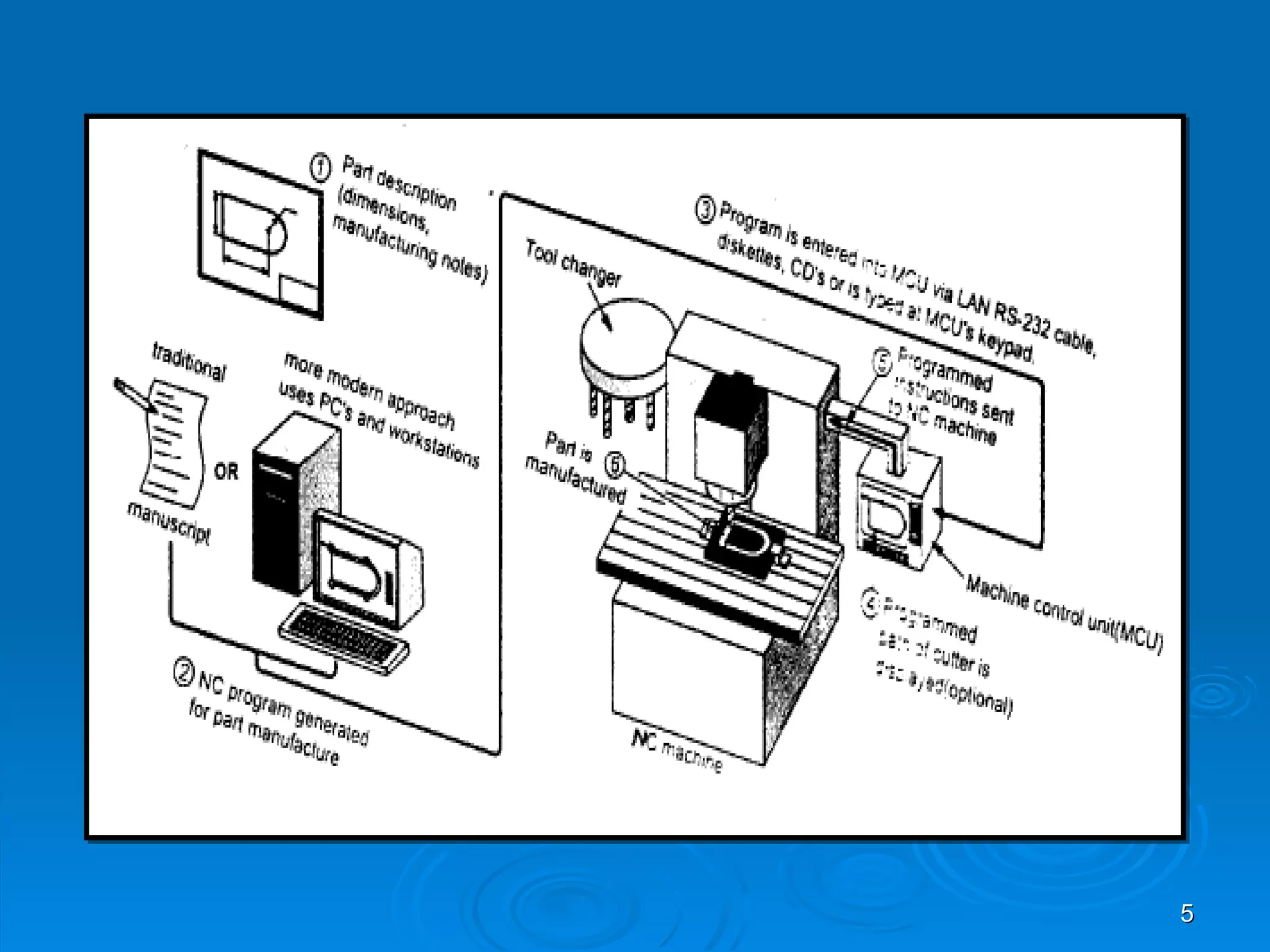

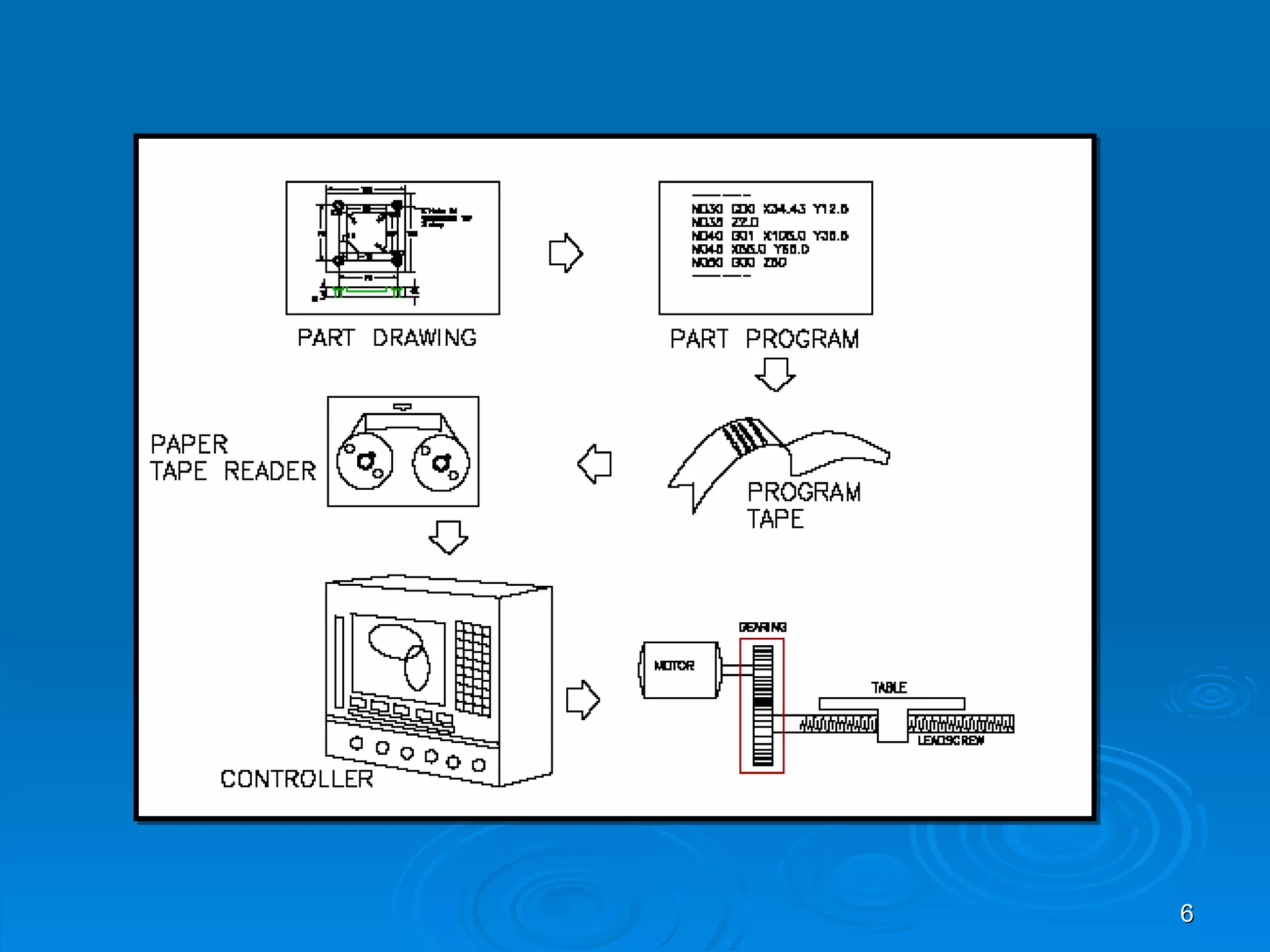

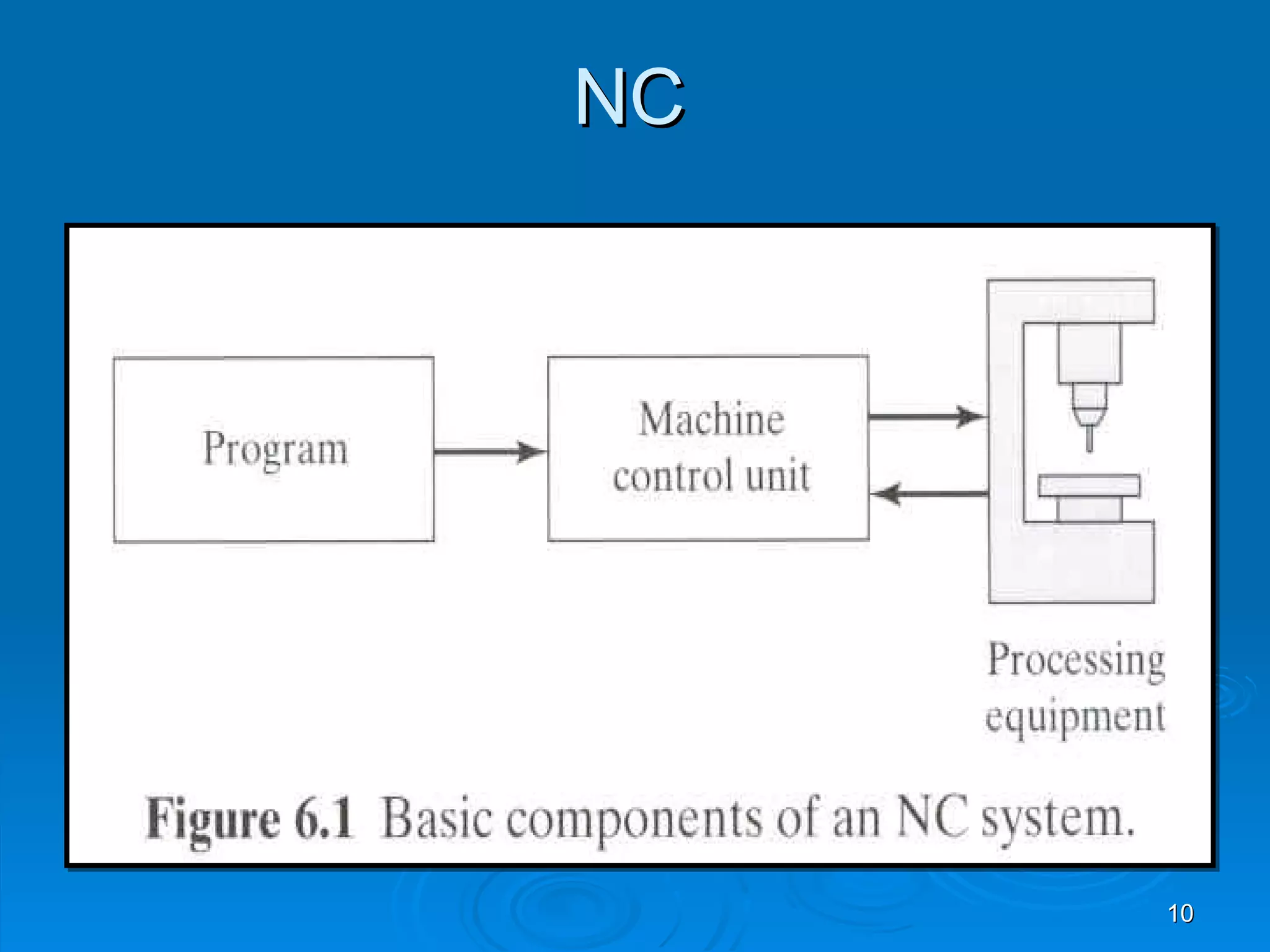

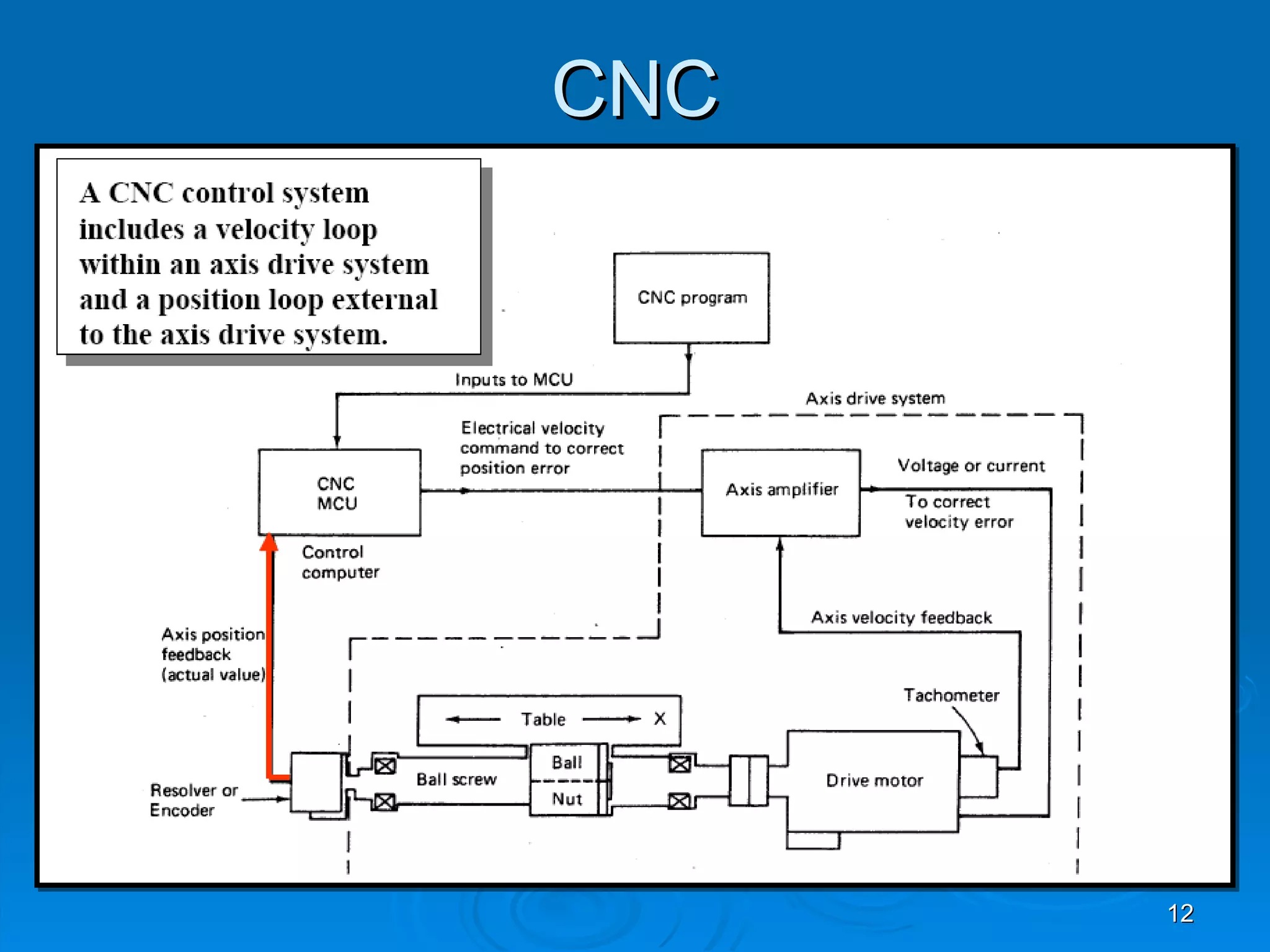

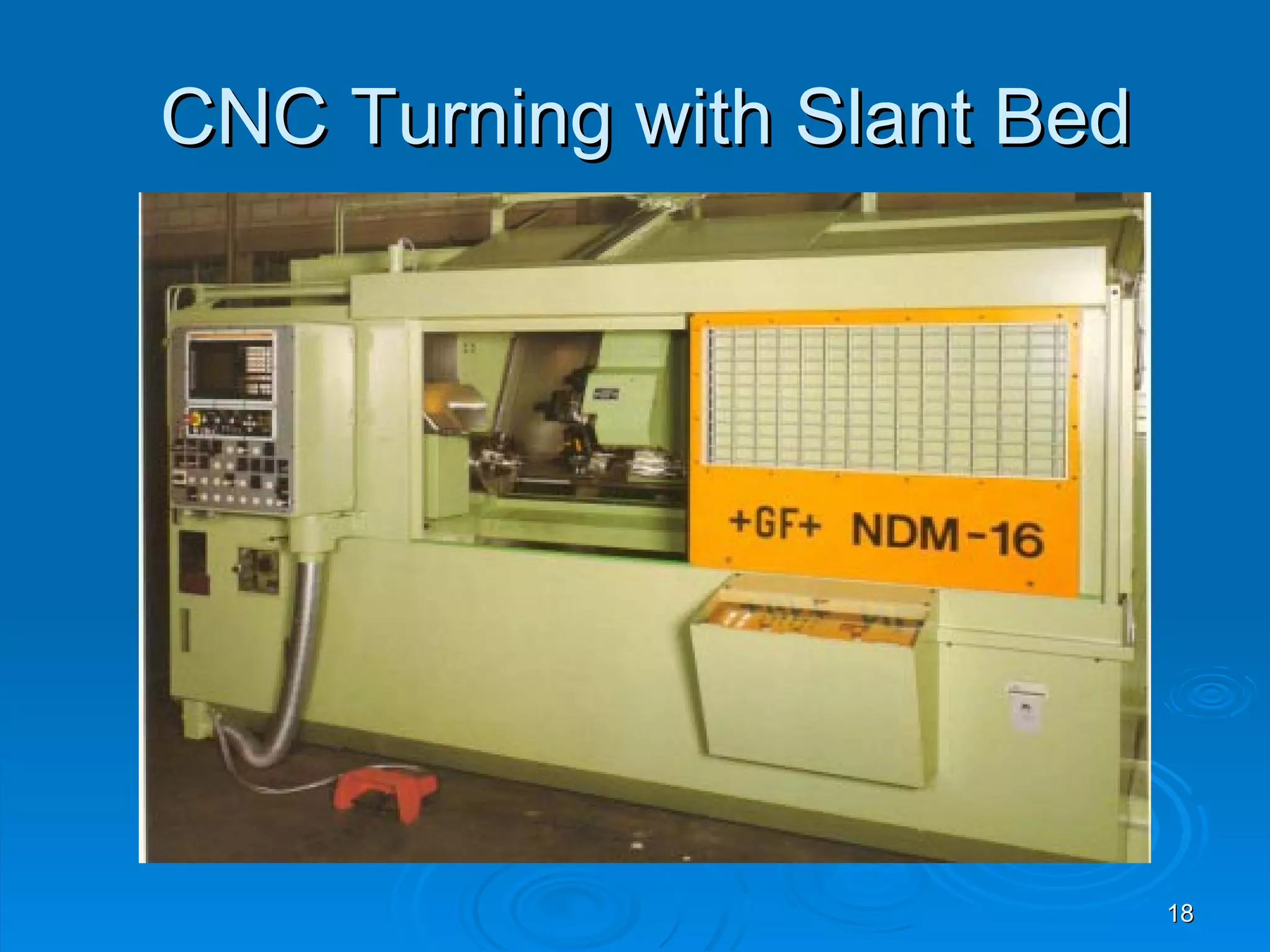

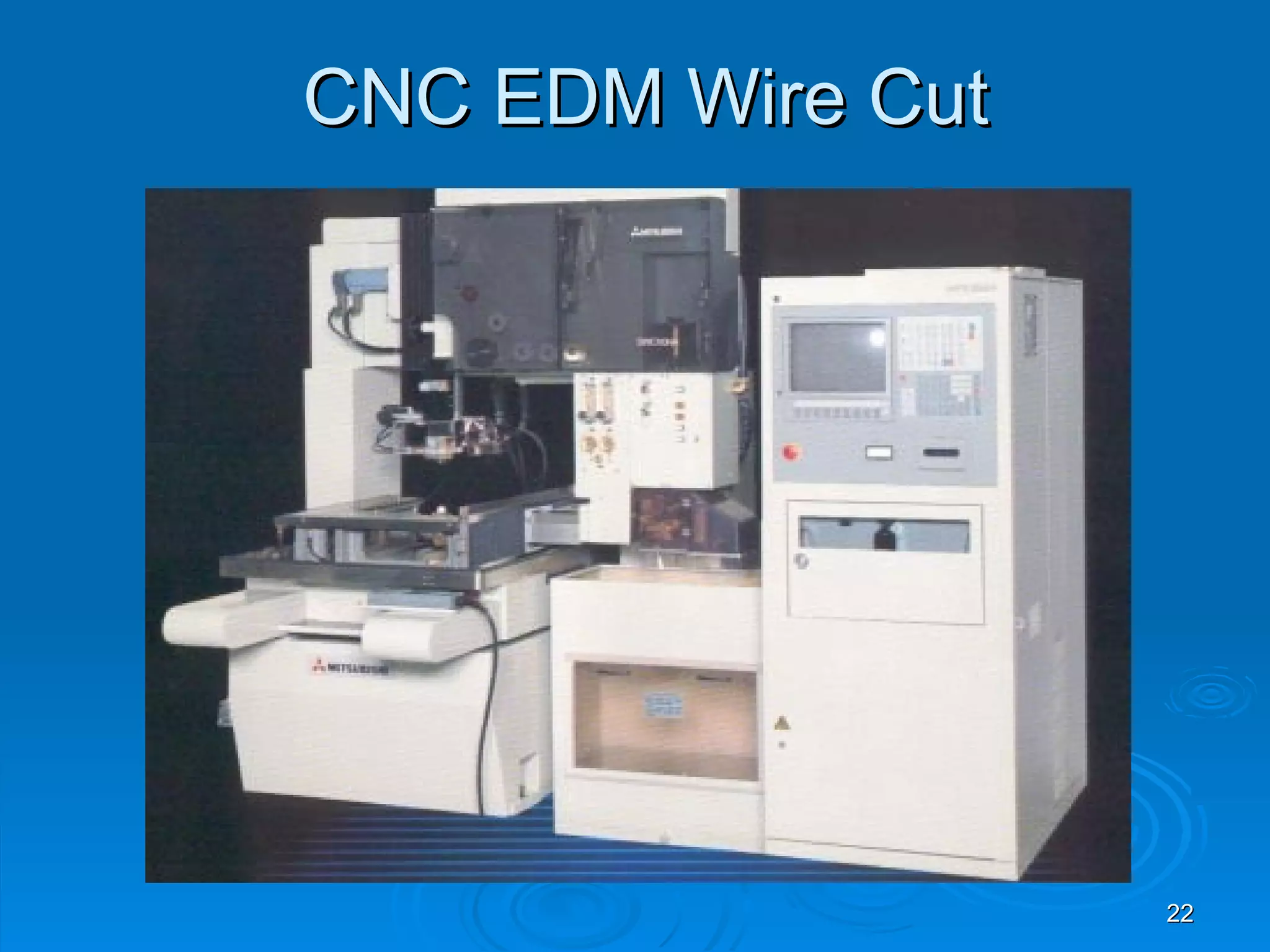

The document discusses the history and technology of computer numerical control (CNC) machines. It explains that CNC refers to computer-controlled machine tools that can be programmed to automatically perform tasks like cutting, grinding, drilling, and milling materials without manual assistance. The summary provides a high-level overview of the key points covered in the document in 3 sentences:

CNC uses computer software and hardware to control machine tools and automate the manufacturing process, allowing complex and precise parts to be machined without direct human assistance. The technology originated from numerical control systems developed in the 1940s-50s and has since evolved to include computer control of machine tools. CNC machines are now widely used across industries like automotive,