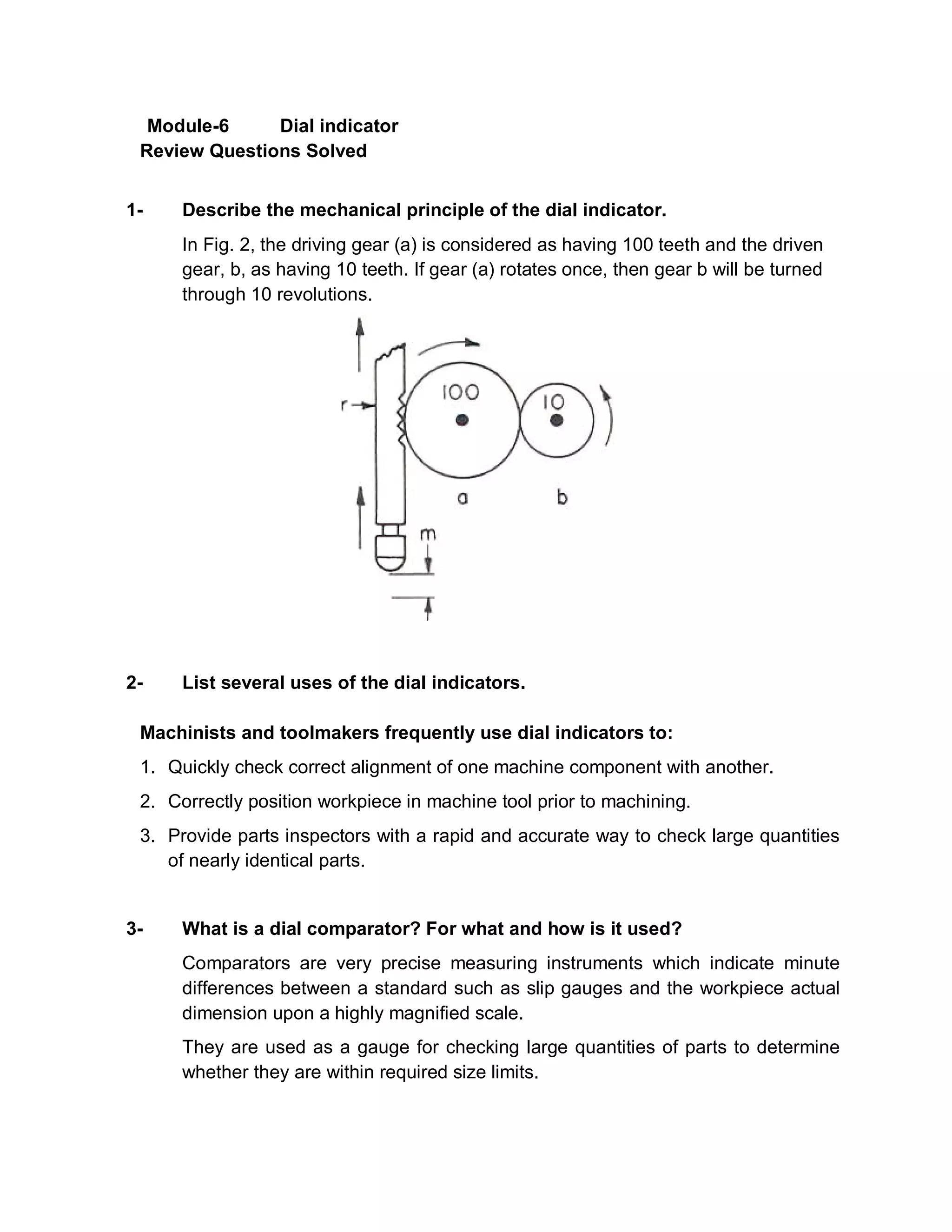

Dial indicators are precision measuring tools used by machinists and toolmakers. They have several uses including quickly checking alignment, correctly positioning workpieces, and inspecting large quantities of parts. Dial comparators are also precise measuring instruments that indicate small differences between a standard and a workpiece on a magnified scale. They are used to check that parts are within required size limits. Balanced dial indicators have figures in both directions from zero while continuous reading types are numbered continuously. There are several types of dial indicating gauges such as snap gauges, calipers, and hole gauges that are used to determine if parts meet size requirements.